Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

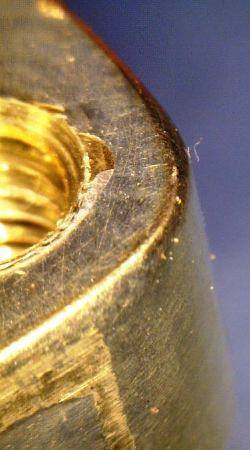

Clear cadmium over Electroless Nickel blisters at masked thread holes

January 31, 2012

Q. Aluminum alloy 6061 T6 shell is experiencing blistering at the thread hole edge that was...

1) masked prior to plating.

2) plating consists of clear cadmium per SAE-AMS-P-416, Type II, .0003" to .0005" thick

3) over electroless nickel per SAE-AMSC26074, Class 4, .0005" to .0008" thick

4) shell is then subject to 151° C heat cure of ink marking for two hours.

Blistering causes plating to flake off when pierced.

Does the masked thread hole expose plating layers after the masking is removed?

If so, do the exposed layers of plating contribute to the blistering effect?

Will heat treatment (temperature/time) of the marked shell violate any SAE-AMS-P-416 or SAE-AMSC26074 requirements ? If so, please state paragraph where requirements will be violated.

Quality Assurance - Irvine, California, USA

Most surely your problem comes from the masking tightness or effectiveness. Chemical plating solutions almost always interfere with the next one. That is why rinsing (and proper masking) are so important.

G. Marrufo

Monterrey, NL, Mexico

February 5, 2012

You have two possibilities.

1: the masking is not solution-tight and thermal differences of solutions might be sucking in some of a colder solution.

I would try putting it in a hot rinse tank for two minutes, followed by two minutes in a clean cold rinse tank. Then plate as normal.

The second possibility is that you are not rinsing adequately. This normally means using considerable agitation in each rinse tank.

Surface tension tends to hold a film of solution on the lower side of the masking.

Threaded holes are not easy to mask. If they are blind holes, I normally used neoprene plugs. Insert with twisting and pressure.If they are thru holes, you can not beat proper silicone pull plugs.

- Navarre, Florida

February 7, 2012

Q, A, or Comment on THIS thread -or- Start a NEW Thread