Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Fine polishing, mirror finish with automatic grinder/polisher

January 25, 2012

Q. Dear All,

I would like to address my question to you, because I know majority of you have a great experience in polishing.

I will explain what I am doing and post a technique I am using below.

I am polishing round samples with a diameter of 1 cm. I trying to achieve as best polishing result as possible, for further experiments in injection moulding.

My samples are Steel samples hardened and tempered to 50 RC.

Equipment: Buehler Motopol 8 automatic polishing machine.

Technique:

1) grinding with Carbimet SiC(800) disc 9 min

2) grinding with Carbimet Sic (1200) disc 5 min

3) polish with Texmet1000 with 1 'nm suspension 4 min

4) polish with ChemoMet with 0.05 'nm suspension 3 min

Problem appears when I am trying to do last step i.e. polish with ChemoMet.

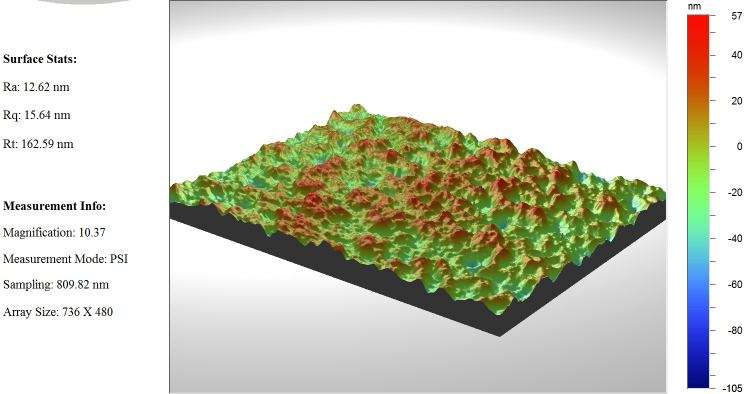

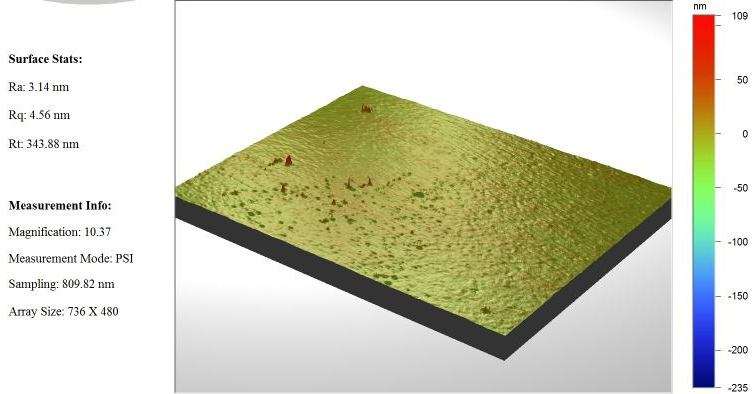

Polishing with Texmet1000 gives me roughness of 3-4 nm Ra.

After polishing with ChemoMet Roughness is approx. 15-20nm Ra.

I thought surface would improve after polishing with ChemoMet, but it actually is not.

Surface looks like it is over-polished and orange peel appears on the surface.

I do know that it could be over-heating or over-carbonisation.

Finally my question, did anyone have the similar problem and what did you do?

I would really hope for your advice.

Regards,

Student - Bradford, West Yorkshire, UK

I am not familiar with the equipment you indicated in your process. The only thing I can be sure of is the appearance you are getting on your parts is a result of too much energy or force of the media against the part. Most machine systems you can adjust energy. Also, need to know if machine system is a mass finishing system and is it done with a liquid?

AF Kenton

retired business owner - Hatboro, Pennsylvania

January 26, 2012

January 26, 2012

Thank you very much for your reply.

This is how Buehler automatic polisher looks like:

www.metallography.co.uk/cms_media/images/500x500_fitbox-buehler_motopol.jpeg

As you can see this is not a mass finishing system.

Grinding is done with liquid.

As for polishing, suspension is mixed with distilled water and applied on a polishing cloth.

I hope this makes more sense.

Regards,

- Bradford, West Yorkshire, UK

January 28, 2012

Thanks for visual. I still am not familiar with system; however. I assume the round table moves and a liquid lubricates the media on the table. Depending on the amount of liquid and abrasives I do not see how the pressure is transferred to the media and the parts. If there is a centrifugal action, my guess is that there is not enough liquid in the system or there is not enough lubricity in the liquid.

AF Kenton

retired business owner - Hatboro, Pennsylvania

January 31, 2012

Hi Max

Speak to Beuhler. You will find them very helpful in assisting you to get the best out of their equipment.

Geoff Smith

Hampshire, England

To achieve good surface finish , why don't you use diamond polishing wheels?

- Shimla, Himachal Pradesh, India

February 14, 2012

Q, A, or Comment on THIS thread -or- Start a NEW Thread