Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Powder coating is thick at sharp corners, and none along the edges

September 25, 2011

Dear all,

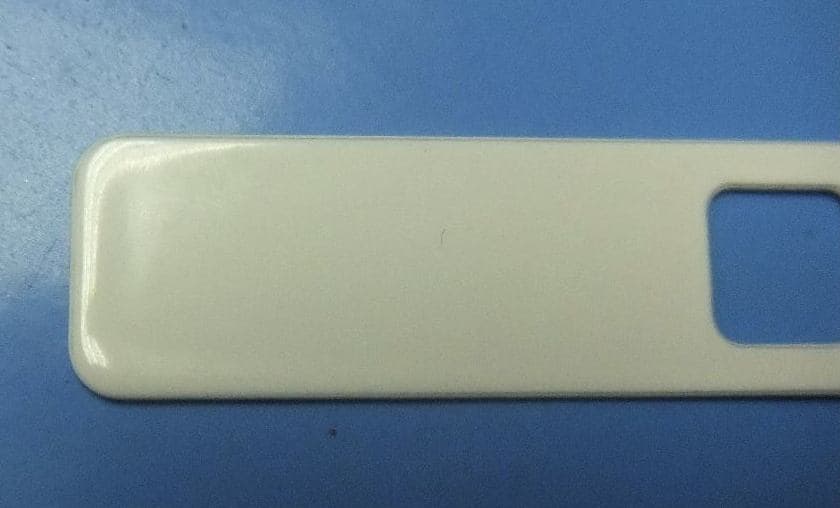

We face a problem about applying powder on a metal surface and hopefully someone with better knowledge can help us on this. Attached are some photos of our current state --

1.) We applied some powder on 0.80 mm stainless steel pieces, and tried to bake two times (1st time 0.05 mm; 2nd time 0.10 mm thick of powder). They turned out to be having thick coating at the 90 degrees corner and at the same time they don't seem to have it along the edges (can see the stainless steel itself), we filed the edges already but it seems the same.

2.) The finished piece of metal have to be in good condition without popping surface after staying in a 65 C distilled water for 7 days. We have some popping after about 48 hours.

What can we do to avoid this outcome and get a even and smooth surface finishing? Please suggest anything possible since this is kinda urgent.

Thanks a lot.

Chris

buyer - Hong Kong

I would surmise that the powder -- possibly polyester, has too much flow and requires some modification to the formula. It is the image you provide that led me to that conclusion-- build up at the lower edge from the hooking point and pull away from other edges.

Terry HicklingBirmingham, United Kingdom

First of two simultaneous responses -- September 27, 2011

Second of two simultaneous responses -- September 28, 2011

It would appear from Photographs that the coating has "sagged"

during cure.

I originally observed this tendency with the introduction of non TGIC powders many years ago.

I suggest you revise your Powder Spec. If you are constrained to non TGIC resin powders you could also introduce a high boost of thermal energy early in the cure schedule.

This could be achieved with an IR Booster in advance of your (assumed) gas fired oven.

That translates to set it quick and cure it routinely.

If that option is not available, you could always preheat the substrate and achieve the same effect.

Hope this helps.

Regards,

Bill

Trainer - Salamander Bay, Australia

Q, A, or Comment on THIS thread -or- Start a NEW Thread