Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Cleaning Copper Bus Bar

Q. I'm trying to find a way to prevent tarnish on the copper busbars that we are cleaning for our factory. I'm using a soak clean, an e-clean and an acid bright dip (sulfuric acid 10%) with a rinse station after each of them. The parts looks good right after unloading from the line but several day after you can see some stains all over the parts. Does anybody have an idea to prevent this issue?

Carlos RodriguezPlating Engineer - Juarez, Chihuahua, Mexico

2007

A. Hi, Carlos. They can be kept bright for a good while with a dip in benzotriazole ⇦ this on eBay or Amazon [affil links] or they can be lacquered. Obviously, lacquer must be kept off the joint area, and is only appropriate if the busbars stay reasonably cool -- but I've seen it done in plating shops with very good result.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

Q. We are having problem cleaning copper bus bar, we have tried using: soak cleans, electrocleans, and also bright dipping. None of these are working for our process. We are silver or tin plating the bars after cleaning. Parts range from 1/8" x 1" x 12' to 3/4" x 8" x 12' can anyone help use with this issue.

Also, we are having a problem with our silver plating peeling. We noticed since we been having this problem that our anodes in both strike and plating baths are gassing and the stainless steel anodes we use have plating on them. Does anyone have any ideas of what is going on with this?

Thanks,

Amanda Noles-McLainElectroplater - Manvel, Texas, USA

August 17, 2011

August 17, 2011

A. Hi, Amanda.

I assume that you've tried soak cleaning and/or electrocleaning followed by a bright dip?

What does the bus bar look like after cleaning and bright dipping? Is it a nice, uniform, bright copper color?

Although insoluble anodes are often used in strike tanks, most silver plating tanks (I believe) use silver anode material.

Insoluble anodes are expected to gas: The rectifier pulls electrons from the anodes and pumps them to the cathode where the surfeit of electrons on the cathode can reduce the Ag+ in the solution to metal plated onto the work. But there must be a way for the anodes to gain/accumulate those electrons from the solution, or current would not be able to flow. When you use soluble silver anodes, the silver dissolves from Ag0 metal to Ag+ generating those necessary electrons. When you use insoluble anodes, the only way for the necessary electrons to be freed at the cathode is by pulling 0-2 from the H2O of the water and converting it to O or 02 which is the gassing you are seeing.

May we also assume that the strike and plating baths have their own rectifiers and there is no chance of the current having been reversed? Because silver is more noble than copper, it can immersion deposit non-adherently on the copper, so the strike tank has to not only be present but to really be working correctly as a strike -- so you might check that.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. We are using separate rectifiers on the strike and plating. The bus bar after bright dipping has a uniform color. We have tried bright dipping some of our smaller parts, just not the 12' ones which we do the most of. The only problem with a bright dip is that it's not safe for the environment. The TCEQ in Texas will not allow the large bright dip due to environmental issues. So we are looking for something safe with the same or better results for cleaning this bar.

Amanda Noles-McLainplating - Manvel, Texas, USA

September 27, 2011

A. Hi, Amanda.

What bright dip chemistry are you using? There are many different chemistries available for bright dipping copper, and a sulfuric acid plus hydrogen peroxide bright dip process may be "environmentally safer" than the bright dip you are presently using, although the bright dip isn't supposed to be in the "environment", it's supposed to be properly kept out of the environment :-)

Vent mode on: I'm against limiting industrial practice to what schoolchildren can safely do at their kitchen table; and it is so foolish to believe, as the TCEQ apparently does, that you can concede the difficult jobs to China but keep the easy stuff. I know a nameplate manufacturer who absolutely did not want to move to China, but the companies he supplied moved to China for their tough stuff, wouldn't put up with waiting for nameplates to come over from the USA and so on -- so the employees all lost their jobs and China got some more. Trying to retain just the easy jobs is the guaranteed way to all of the jobs :-(

Good luck!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

September 2011

Cleaning Copper Bus Bars

Q. I am trying to clean some solid and also some laminated copper buss bars to use in an EV restoration. I know it would be better to use plated ones today but these were original equipment. How did the manufacturer finish them so they stayed nice so long. My attempts with various kitchen chemicals prompts immediate oxidation.

Chris Murphy- Roseland, New Jersey, US

August 16, 2019

A. Hi Chris. I don't know what products you included in testing "various kitchen chemicals", but did you try copper cleaners like Brasso ⇦ this on eBay or Amazon [affil links] , Barkeepers Friend ⇦ this on eBay or Amazon [affil links] , or Twinkle Copper & Brass Cleaner ⇦ this on eBay or Amazon [affil links] ? Any of these products should work to at least some degree. If not, we can suggest industrial approaches.

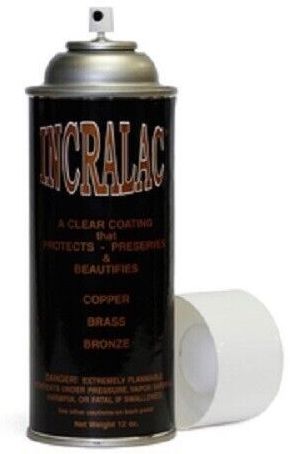

Keeping the copper bright for longer periods involves either a dip in benzotriazole or application of brass lacquer ⇦ this on eBay or Amazon [affil links] or preferably both. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

August 2019

Q. So, using the stand by of vinegar ⇦in bulk on eBay or Amazon [affil links] and salt which gets copper spotless, would rinsing and drying be necessary? I would think so. At what concentration would you use this product for a final dip?

Chris Murphy [returning]- Roseland, New Jersey, US

August 28, 2019

A. Hi again Chris. Despite it being cheap & effective, and safe for people, vinegar plus salt does have some disadvantages. If it's working well on your high purity copper bus bar, fine; but it is quite corrosive and discolors some copper/brass alloys, leaving them raw colored instead of warm. I would say, yes, you should do a good job of rinsing that vinegar and salt off of them.

Benzotriazole is used as a 0.1% to 2.0% solution in dipping applications like this. People don't usually buy it as a laboratory chemical, but as a proprietary from companies like Cobratec or from metal finishing process distributors where you get a technical data sheet for its use in your application. Alternately you can apply a brass lacquer like Incralac which includes benzotriazole -- unless your vinegar plus salt causes the copper to tarnish before you can do so.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

August 2019

Q, A, or Comment on THIS thread -or- Start a NEW Thread