Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

One anodizer can make shiny parts, one can't

April 18, 2011

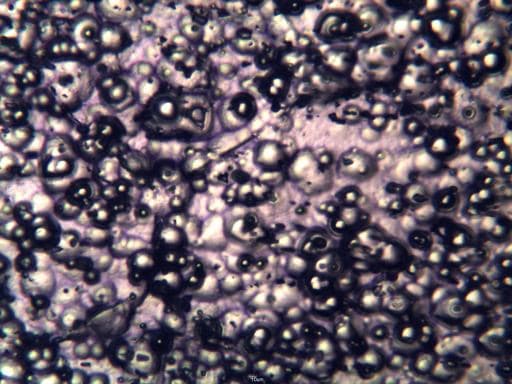

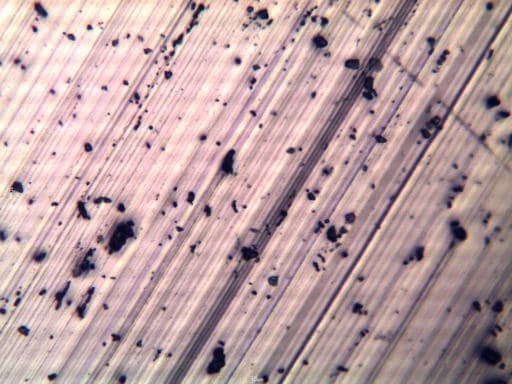

We've got an anodizing mystery -- two anodizers, one makes beautiful, clear, shiny parts, the other's parts are dull and lifeless looking.

Both get the same stock 6063-T4 extrusion, they are both plating to the same spec (MIL-A-8625F Type II Class 1, 12-16 µm thick).

I've included 1000X pictures of the dull surface and the shiny; hopefully this will look familiar to someone and we'll be able to provide feedback to the misbehaving vendor.

Engineer - Fremont, California, USA

Roger

I would suspect the pretreatments are different. You could ask both suppliers to pull a part off the rack immediately prior to anodize and examine.

- Colorado Springs, Colorado

First of two simultaneous responses -- April 19, 2011

Two different shops can "meet" the Mil Spec but have different (1) free acid and/or (2) different temperature, and/or (3) different current density, (4)etch differences (this is probably yours judging by the lines in the pictures,) and several other factors. If cosmetics is an issue, the supplier should be furnished a sample finish to "shoot for" and be sure to tell him the tolerances on the machine parts.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Second of two simultaneous responses -- April 19, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread