Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

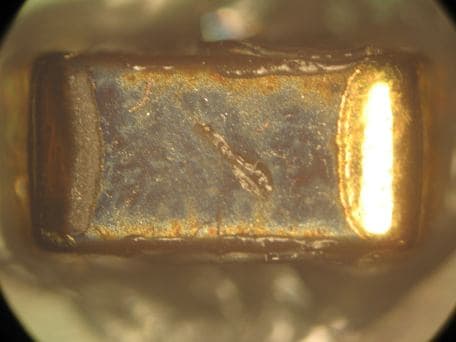

Gold Plating Lifting from Nickel on Ceramic Capacitors

April 11, 2011

Hello, I'm a process engineer for Gold Electroplating on MLCC. I recently have some lifting or peeling termination from our ceramic capacitors , we applied a tape test after 8 hours steam age, the gold plating layer and in some cases the Nickel layer and Silver base metal are lifting too. I tried the tape test with Nickel layer only and there is no lifting . I need some help to understand what could be wrong with Gold Plating Bath or process , current controls are pH, specific gravity , temperature and gold concentration.

Thank you for your time and help.

Plating PE - Monterrey, Mexico

April 23, 2011

See attached paper

Electroless nickel plating onto bare ceramic (except AlN)

It is possible to plate directly onto a ceramic surface without first "metallizing" the surface with a "painted on" or screened metal frit. Preparation for plating directly on a ceramic surface takes many forms. The basic requirements are: proper cleaning, a means of developing micro-porosity in the surface to produce maximum adhesion, a means of making the surface catalytic to an electroless plating solution, and a suitable electroless plating process.

Ideally, a slightly porous surface (where interlocking of plating in the pores with the surface deposit can occur) will produce maximum adhesion. The adhesion is comparable with the bond strength achieved by fired-on metallization coatings. The bond strength diminishes to bonds of 1 to 5 pounds pull (1 inch wide strip), as the porosity becomes less than ideal. Resin and organic and organic coatings as preparation materials have produced bond strength of from 2- 15 pounds pull. Porosity in the ceramic surface can be controlled somewhat by the conditions under which the ceramic device is produced. The composition of the ceramic also plays a role in whether or not porosity of a suitable nature can be produced. Where there is a little or no porosity in the ceramic surface, it can sometimes be developed by etching in mixtures containing fluorides. Ninety seven percent alumina is an example of a ceramic that can be etched in fluorides to develop micro-porosity. Lumina cannot be etched effectively to develop micro-porosity suitable for plating. An alternate procedure is to immerse the ceramic in a 10% solution of KOH followed, by heat treating at 450° C for 10 minutes.

PLATING ONTO ALUMINA CERAMIC

1. Alkaline clean to remove fingerprints and other soils. Ultrasonic energy aids cleaning and helps remove ceramic fines entrapped in the pores.

2. Rinse ( ultrasonic is preferred_)

3. Etch in a fluoride-containing solution such as ammonium bifluoride 60-120 g/L or hydrofluoric acid or a mixture of the two, for 2-20 minutes depending on the nature of the ceramic. The addition of 100 g/L NaCl can enhance the adhesion of the subsequent deposit.2 ( see also above for KOH etching using heat treating)

4. Rinse (ultrasonic is preferred)

5. Sensitize in a dilute solution of stannous chloride (10 g/L plus 10 ml/L HCl) 1 to 2 minutes at room temperature.

6. Rinse in DI water

7. Catalyze in a dilute solution of palladium chloride (1 g/L plus 10 ml/L HCl) 1-2 minutes at room temperature.

8. Rinse in DI water

9. Electroless nickel plate

10. Rinse

11. Electroplate (optional)

12. Rinse and dry.

PLATING BARIUM TITANATE CERAMIC

1. Alkaline clean (see above method)

2. Rinse ( ultrasonic)

3. 3 Etch (see above method)

4. Rinse in DI water (ultrasonic)

5. Sensitize in stannous chloride (see above)

6. Rinse in DI water.

7. catalyze (see above method)

8. Rinse in DI water.

9. Electroless nickel plate

10. Rinse

11. Electroplate (optional) Use copper, gold, silver or rhodium or as required

12. Rinse and dry.

Note: other ceramic materials have been plated using these processes and modification thereof. Examples or other ceramics plated are: Yttria, stabilized zirconia, lead zirconate, (acetic acid

⇦ this on

eBay

or

Amazon [affil links] is added to the etching solutions), garnet ceramic, zirconium oxide, lithium noibate and ferrites.

Don Baudrand

Consultant - Poulsbo, Washington

(Don is co-author of "Plating on Plastics" [on Amazon or AbeBooks affil links]

and "Plating ABS Plastics" [on Amazon or eBay or AbeBooks affil links])

Thank you for your response Don , I forgot to mention that we first apply silver metallization paste , then we plate Nickel and then Gold . The peeling termination is a result of a tape test after 72 hours aging . If we perform the tape test after Nickel plate we don't experience the defect .

Rigoberto Galvan- Monterrey, Mexico

May 9, 2011

The nickel is obviously passive (oxided). You must find a way to re-activate (reduce) the nickel surface. I recommend a nickel chloride strike (2#/gal Nickel Chloride, 2 pints per gallon HCl, Rolled Depolarized Nickel Anode (not S-rounds). Sometimes, if the nickel has been "fired", you want to dip in hot HCl ahead of the cold nickel chloride strike. Also, you need a gold strike; talk to your gold supplier.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

May 10, 2011

All the answers are very good for your testing.

Try to re-fire the silver (Fire it 2 times at 850 deg c), then go to Ni plating, if it did not help then you need to reduce the Ni thickness or run 2 to 4 hours annealing (for the Ni) after plating.

- mission viejo, California

December 14, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread