-----

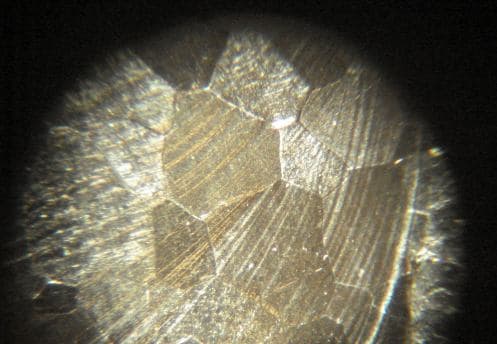

Polygonal Surface Cracks on Alpha Beta Titanium Welds

WE are trying to weld Grade 5, 6AI-4V Titanium and using similar filler material. We have constructed a glove box assembly which is used to purge out room air using argon. We are also using Argon as the inert welding gas for the GTAW process. Upon completion and inspection of the weld under 3X magnification we are experiencing surface cracking issues in the shapes of 5-6 sided polygons. What is causing this? Cooling the weld to fast? Overheating during welding? The cracks do not seem to propagate all the way through the joint but are several thousandths of an inch deep.

Design Engineer - Golden, Colorado, USA

March 14, 2011

It has been a very long time, but I think that it was caused by too much heat in the part.

To prevent the blue alpha case, you really need to purge the welding area with a gas-vacuum -gas-vacuum-gas sequence.

Since you are working on 6-4, I assume that this is an aircraft part.

Large crystal like formations can cause the part to shatter when it is dropped or hit with a hammer.

- Navarre, Florida

March 15, 2011

We purge the entire box using a vacuum-gas-vacuum-gas method to escape most or all impurities in the purge box environment, using 99.9 pure argon. We have an oxygen meter to verify o.o% oxygen is present in the environment. The welds come out very clean and silver with no brown or blue discoloration of the metal on either side of the weld.

So contamination has to be to a very minimal if any at all judging by those factors. I guess now it has to be like you suggested there heat change is to quick for Ti.

I did some calcs on how much heat were putting per inch and on average were putting in 16704 J/in. I don't know if it is important but possibly? Does anyone know if there is a good range temp or joules to be putting into a 0.100 thick butt weld?

- Golden, Colorado, U.S.A.

March 18, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread