-----

Anodizing trouble with aluminum alloy 1050

February 22, 2011

Hi I'm Joe M R. I'm an industrial and Systems Engineer.

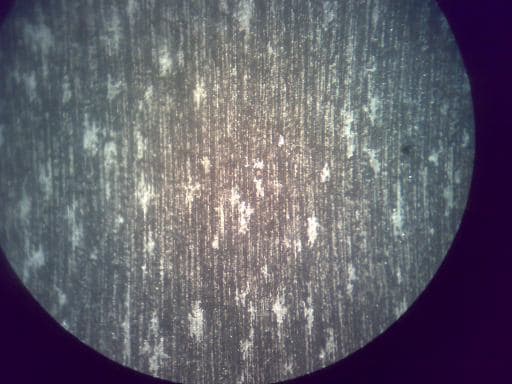

I'm anodizing aluminium alloy 1050 in natural shiny finish, my trouble is before the anodize, in polish step because here appear marks like very short pits. It happened in one or two pieces of 20 that be in the same rack but why appear just in some pieces? If I anodize this pieces the marks continue there and give bad finished product.

The alloy guarantee uniform pieces so why only some pieces be affected ?

In other proof I use the same alloy of two different manufacturers and just one of them comes to be affected, in the same way. It's an acid percentage problem? (sulfuric, phosphoric, nitric)

or is it some element of the alloy? please give to me some guide. I'm sending some photos of damaged pieces.

Joe Mendez Rocha

OEM company - Mexico City, Mexico

Anodizing typically highlights any flaws that are in the material prior to coating. If you are noticing these after your polishing steps, then that's where your problem lies.

I'd look closely at your polishing process, insuring that you aren't embedding anything into the aluminum. If you're using sandpaper, make sure it's aluminum oxide based.

Marc Green

anodizer - Boise, Idaho

February 24, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread