Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Welded galvanizing kettle will have a short extra joint

for Engineers, Shops, Specifiers

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from Amazon

"User's Guide to Hot Dip Galvanizing for Corrosion Protection in Atmospheric Service" by NACE (1997 only rarely avail.)

avail from AbeBooks, or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

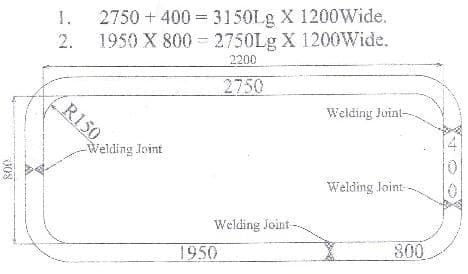

SIR, I AM A HOT DIP GALVANIZING PLANT OWNER IN NASHIK India, I HAVE PLACED AN ORDER FOR A FRESH KETTLE WITH 50 MM PLATE - STEEL - DSQ QUALITY PLATE.

AS PER THE DRAWING BY THE MANUFACTURER, HE HAD ORDERED THE PLATE AND ACCORDINGLY HAD STARTED THE CUTTING.

AS PER OUR DISCUSSIONS BEFORE FABRICATION - THE KETTLE MANUFACTURER HAD COMMITTED A 2 JOINT KETTLE.

HOWEVER POST CUTTING OF PLATE IT SEEMS THAT HE HAD CHANGED THE PLANS FOR TWO JOINTS, INSTEAD OF WHICH HE IS PROVIDING 4 JOINT KETTLE.

NOW CONFUSION ON OUR DECISION MAKING PART IS THAT OUT OF THE FOUR JOINTS IN THE KETTLE - 2 JOINTS ARE COMING AT A SHORT DISTANCE OF 400 MM ONLY.

OUR QUESTION ON THIS PART IS THAT - AS PER MANUFACTURER'S COMMITMENT ABOUT SEAMLESS JOINT -- WE WANT TO MAKE SURE WHETHER MORE JOINTS IN THE KETTLE - WILL EFFECT THE LIFE SPAN OF KETTLE - OR WHETHER THERE IS ANY BENCH MARK REGARDING THE MANUFACTURING OF SUCH KIND OF SHORT PLATE

IF YOU HAVE ANY INPUTS KINDLY DO LET US KNOW -

REGARDS

industrialist - Nasik, Maharashtra, India

February 15, 2011

Sir:

What are the kettle dimensions including depth? Is the furnace high-velocity end-fired or flat-flame side-fired?

Regards,

Galvanizing Consultant - Hot Springs, South Dakota, USA

Dear MR. Sagar

It seems your manufacturer had made joints as per available size of plate with him to reduce the wastage, instead of having two joints nearby , it's better to be have either two joints or four joints with all four corners and it should be around 350 - 400 mm from the end.

regards.

Gunatit Builders

Manjalpur, Vadodara, Gujarat

I think the most important question is burner type and location (as per Dr Cook's question).

If the welded joint is downstream of any high velocity burner flame then reject the proposal. The flame area in high velocity burner kettles is the sensitive area.

Geoff Crowley

Crithwood Ltd.

Westfield, Scotland, UK

Dear Sir..

Generally in India , we have long flame burners as we don't have high velocity burners availability especially for Galvanizing plant, and Burners which we are using are suitable for Furnace oil, one kind of thick crude oil and that's why we prefer four joints or two joints kettle, depending on available size of steel plate.

As per given size by mr. Sagar, it seems this kind of kettle can be fabricated with two joints or four joints..

regards

Gunatit Builders

Manjalpur, Vadodara, Gujarat

Q, A, or Comment on THIS thread -or- Start a NEW Thread