Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Removing carbon layer from mild steel

⇦ Tip: Readers want to learn from Your Situation 🙂

many readers skip abstract questions.

[editor appended this entry to this thread which already addresses it in lieu of spawning a duplicative thread]

Q. How to clean carbon ? deposits or are they ... I really hope someone can help searching on Internet bicarbonate of soda but don't work.

- Peretborough cambs [Peterborough UK]

February 2, 2024

A. Not knowing what these deposits are on, or how they got there, I can't hazard a guess as to whether they are carbon or not.

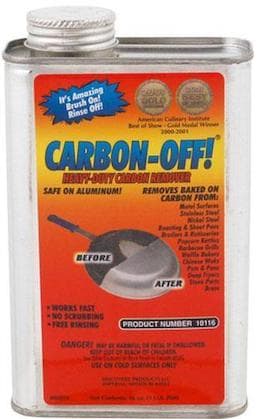

But there is a commercially available product called "Carbon-Off"

⇦ this on

eBay

or

Amazon [affil links]

. Note that it contains 40-70% methylene chloride plus some other nasty materials, so gloves

⇦ this on

eBay or

Amazon [affil links] , goggles

⇦ this on

eBay or

Amazon [affil links] and excellent ventilation are required. Personally, I can't recommend spraying or aerosolizing methylene chloride, so I'd suggest the liquid version and working outside, from upwind.

I don't think bicarbonate of soda will do anything as a chemical solution. But people might have been talking about using a soda blaster [soda blaster on

eBay

or

Amazon [affil links]

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi you have to excuse me, not very tech savvy. I've read some of your stuff so I know you know what you are talking about. I'm trying to clean these in picture.

They're off top of cooker made of cast aluminium, and need cleaning they are black with burnt on oil splashes or carbon? Hope you can help.

Bobhope gill [returning]- Peretborough cambs [Peterborough UK]

February 3, 2024

A. Hi again. If you don't like the Carbon-Off idea, or it isn't available to you, Thread 41066 has several entries about aluminum cooktop burners. Among the suggestions were Silvo metal polish

⇦ this on

eBay or

Amazon [affil links] and Brillo

⇦ this on

eBay or

Amazon [affil links] .

But doing this manually with metal polish or a Brillo pad sounds like it might take forever. I'd suggest trying a polishing buff on a Dremel

⇦ this on

eBay or

Amazon [affil links] or a Mothers powerball mini

⇦ this on

eBay or

Amazon [affil links]

on a low-power battery-operated drill, using a compound like Mothers Aluminum & Magnesium Polish

⇦ this on

eBay or

Amazon [affil links]

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

⇩ Related postings, oldest first ⇩

Q. Sir please help me to remove a hard black carbon layer from ms plate by using any alkaline based treatment.

Hemant Sharmaowner of company - Faridabad, Haryana, India

December 14, 2010

A. Dear Mr. Sharma,

You can try the following steps:

1. Hot Degreasing

2. Anodic Cleaner (I)-High Alkaline

3. Acid Pickling - HCl 40% v/v + inhibitor or and accelerator

4. Anodic Cleaner (II) - High Alkaline

5. Acid Dip

6. Next treatment.

We tested and got good result.

Try and you can see the result.

Good luck.

Best regards,

- Jakarta, Indonesia

January 21, 2011

A. A high pressure water jet can be very effective. Don't try it on small parts - it will throw them all over the shop.

Geoff Smith

Hampshire, England

January 22, 2011

A. Dear sir

first what kind of metal finishing you will make in the surface of this carbon steel ?

if you will make any kind of electroplating you must work in the following sequence

1- hot soak chemical degreaser

2- cold rinsing

3- hot cathodic degreaser

4- rinsing

HCl 40% by volume at room temperature

5- rinsing

6- hot anodic degreaser

7- cold rinsing

7- complete the sequence of electroplating

if you will painting it you must make the following sequence

1- hot soak or spray pre-chemical degreaser

2- hot soak or spray chemical degreaser

3- hot (50- 65 °C ) sulfuric acid 8 - 10 %

4- cold rinsing

5- cold rinsing

6- alkaline passivation

7 hot dryer

best regards

metal finishing - Egypt

February 17, 2011

A. Lots of ways and options. Put a picture of the part on to enable select the right one for you.

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

March 19, 2011

A. In addition to one of the pre-treatment sequences already mentioned, the use of an ultrasonic transducer in the first rinse after the sequence should help to remove any residue that is still on the steel.

Lyle Kirmanconsultant - Cleveland Heights, Ohio

March 23, 2011

A. The advice given is good. Just one final comment. Are you sure it is carbon? It could very well be iron oxide.

Guillermo MarrufoMonterrey, NL, Mexico

March 29, 2011

A. Remove carbon from steel, steps:

1.soak

2. Ultrasonic.

3. Rinse

4. 40-50% Hydrochloric acid

5. rinse

6. 40% hydrochloric acid

7.rinse

Popatbhai B. Patel

electroplating consultant - Roseville, Michigan

May 14, 2024

Q, A, or Comment on THIS thread -or- Start a NEW Thread