Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

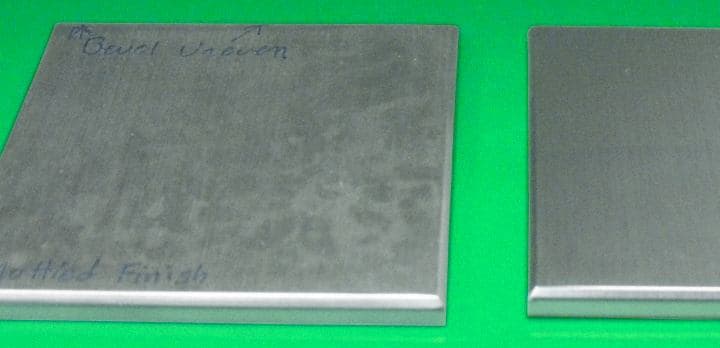

Blotchy Decorative Electroless Nickel

November 29, 2010

I am a design engineer. This is an electroless nickel finish. I have had this same issue of blotchy finish with multiple suppliers.The plate on the right is the desired finish. The plate on the left is blotchy.

Where should I be focusing my attention to find the root of this problem? Cleaning, rinsing, brightener, etc.? Any help in understanding the cause and cure for this would be greatly appreciated.

Product Designer - Bally, Pennsylvania, USA

Let's start with the base metal, what is it? Then what is the alloy?

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

First of two simultaneous responses -- November 30, 2010

Your blotchy panel looks exactly like an aluminum that got water in between the sheets and had a surface corrosion. It does not matter how much you clean or etch it,it will look like your panel. Sometimes you can sand it with an orbital sander using progressively finer grits and have it look decent.

If you can stand a matte finish, glass beading might work, but if this panel has any size to it, it will take a very rare operator to not have patterns from the minor differences in angle/distance and speed of the gun.

- Navarre, Florida

Second of two simultaneous responses -- December 1, 2010

The base material is 260 cartridge brass.

Joseph Nichols- Bally, Pennsylvania, USA

December 2, 2010

Ok, but it still looks like corrosion. Possibly the entire part is not active. Possibly, you are not putting on enough EN, even 'tho the parameters appear to be similar to those in the past. How are you testing for thickness?

Durney's book, says to look for something that changed when a problem shows up for a first time. There are lots of places to look in a plating line. Vendor quality is a place that I normally start with, especially if I changed products that are " identical".

- Navarre, Florida

December 3, 2010

December 7, 2010

Since you looked at numerous suppliers and see the same thing, cloudy deposits, it is not an EN issue but a cleaning issue.

The brass probably has an anti-tarnish chemical on the surface and you will probably have to etch the surface to remove it.

George Shahin

Atotech - Rock Hill, South Carolina

December 16, 2010

I hope your first layer is a nickel strike.

Do not plate EN directly on brass with no strike

Sara Michaeli

Tel-Aviv-Yafo, Israel

Q, A, or Comment on THIS thread -or- Start a NEW Thread