Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

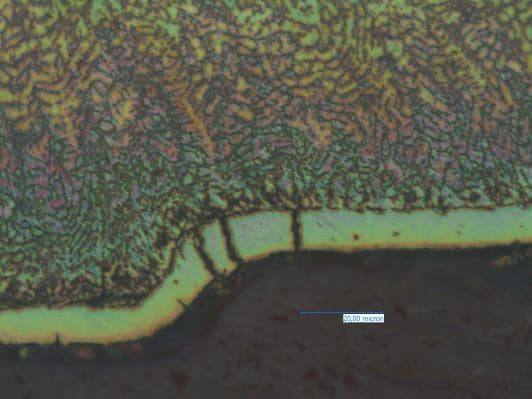

Zinc Plating is Cracking

We apply a layer of electroplated zinc (about 10-15 microns thick) on zinc-aluminium castings. Once the items are working (automotive structural parts) sometimes transversal cracks are observed through the layer (no corrosion evidence at all). Could they come out from wrong electroplating parameters (temperature, chemistry) causing tensile residual stresses inside the coating?

R&D - Carpi, Italy

September 15, 2010

Hi,

What is the chemistry of the zinc plating process? Acid base can cause more internal stress in the layer than the alkaline base process.

Saludos

Jobshop - SLP, Mexico

September 28, 2010

Hi,

WHAT TYPE OF PASSIVATION IS ON YOUR ZINC PLATING? WHAT IS THE TEMPERATURE OF DRYING? LOWER THE TEMPERATURE OF DRYING. HIGH TEMPERATURE WILL CRACK THE CONVERSION COATING BY DEHYDRATION.

- KOLKATA

October 9, 2010

Q, A, or Comment on THIS thread -or- Start a NEW Thread