-----

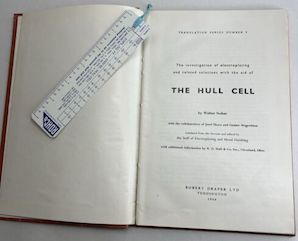

Hull cell: 267 ml vs. 1000 ml size

Q. My company electroforms large diamond turned and structured panels, off of electroplated copper plates passivated with electroless nickel. I am in the process of trying to get our MacDermid bath under better control, and will be implementing some bi-weekly testing procedures using a Hull Cell

⇦ huh?

and some other protocols. What I was wondering what size Hull cell I should purchase for this testing. I am leaning towards the larger 1000 mL cell, but I don't have a great reason other than that it allows me to do a little more testing before the small bath goes off. Our plating bath is relatively large, 350+ gallons.

For now I plan on purchasing a heated Hull cell, with air agitation, titanium basket that I can put S-rounds in, and anode bags. I just need to decide on the size of the bath itself.

Any thoughts?

Engineer - Philadelphia, Pennsylvania

August 30, 2010

A. Dear David Casale,

I have no experience with the 1 liter cell and a lot with the 267 ml one.

I can only imagine myself that the larger scale makes the handling a bit more difficult, especially in cases where you try to modify your electrolyte to the optimum conditions (based on the visual impression of the HC-panels) and have to try out different additions and not in incrementing amounts, however I don't know if this is a situation which you will often have. If using the 267 ml. cell, a good practice is to produce only one Hull cell per "electrolyte shot" and empty and refill for the next HC. In your place I would also think about e.g. thin base material as cathode and look at the deformation of this panel after the HC plating too.

Furthermore I have no important arguments pro and contra and I'm curious to learn arguments in favour of the 1 ltr cell.

Other considerations is if the HC still fits in a scientific approach where you can (and maybe should) analyse your electrolyte via CVS, ICP-MS

⇦ on

eBay

[affil link]

, Polarography, HPLC etc. The HC will only indicate appearance changes and you should hope it does before you have already trouble in you're electroforming process.

I know that I probably will arouse a lot of people with this remark, but I really think that the analytical capabilities are severely improved since the times of Mr. R.O. Hull, as such I would use the Hull cell only to determine limits for certain (appearance influencing) contaminants / breakdown products, or use it for the "determination" of brightener(s) needs if the brightener(s) cannot be analysed.

Best regards,

Harry van der Zanden

consultant - Tilburg, Netherlands

A. The 1 Liter size allows for a more convenient and intuitive conversion if you control your tank solution in g/L. That is the only reason for the larger size. The 267 mL cell was based on a convenient oz/gal conversion. Most people still just use the much more common 267 mL cell and they do the necessary math conversion before making adjustments to their process tank.

Jon Barrows, MSF, EHSSC

Kansas City

Q, A, or Comment on THIS thread -or- Start a NEW Thread