-----

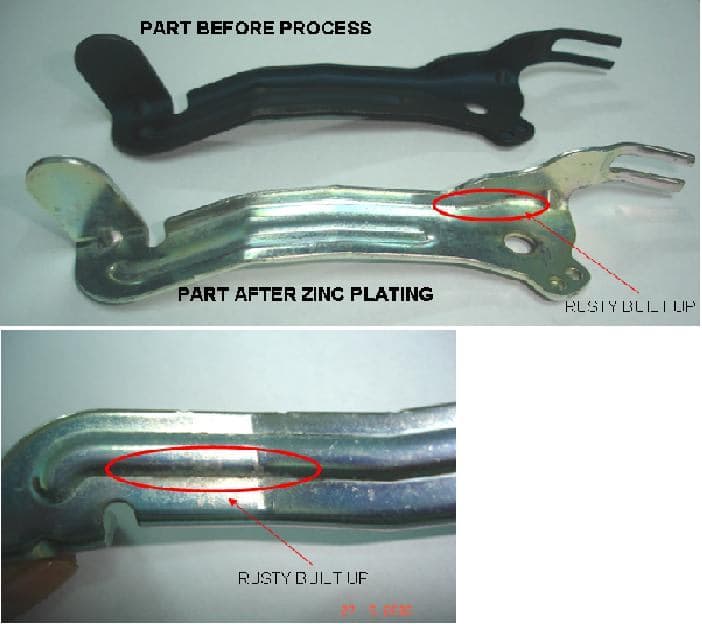

Is sulfuric acid pickling okay for hardened parts

I'm doing zinc plating with sulfuric acid pickling and cathodic cleaning in pretreatment line. We found difficulty on doing hardened part, because after several days sometimes white rust appears all over the part, meanwhile other parts still OK. Can sulfuric acid cause this problem? Can you explain to me how it works? For your information our plating is alkaline type. And our flow process for hardened part is: pickling (H2SO4: 100 cc/L) 2 min, anodic clean 3 amp/dm2 3 min, cathodic cleaning (H2SO4 100 cc/L) 2 Amp/dm2 4 min, anodic clean 3 amp/dm2 3 min, activation (HCl 50 cc/L) 1 min, than go through to plating. Thanks for all

plating shop employee - Bekasi, West Java, Indonesia

May 27, 2010

Gentleman,

I feel Anodic cleaning in Alkaline potassium permanganate

⇦ on

eBay or

Amazon [affil link] is suitable followed by mild acid dip in HCl is sufficient to have better coverage instead of having anodic and cathodic sulfuric acid cleaning.

Another option is, you can use caustic soda ⇦liquid caustic soda in bulk on

Amazon [affil link]

and sodium cyanide mixture with PR cleaning also suitable for Hardened parts.

All the best

Shankaranarayanan N

- Bangalore, Karnataka

June 3, 2010

June 5, 2010

Dear Mr. Joko (Pak Joko - Indonesia language)

I know your problem very well, it's happened a lot in our area due to bad material and treatment system, sometimes the oil quality also very low grade.

My team has successfully help our customers by using as follows:

1. Degreasing - 10 minutes (demulsifier type with oil separator unit)

2. Anodic Cleaning - 5 minute - 5 A/dm2 (Very high alkaline cleaner with descaler properties)

3. Pickling - less than 5 min due to heat treated steel/hi-carbon steel, HCl : 35%~50% by volume, plus Pickling Accelerator Additive+Pickling Inhibitor to prevent material to be attacked by Strong Acid

4. Anodic Cleaning - 5 minutes - 5 A/dm2 (same chemicals as no.

2)

5. Acid Dip - HCl 5% - 1 minute

6. Alkaline Dip - NaOH :5% - 1 minute

7. Alkaline Non-Cyanide Zinc

Please try, and let me know the result, Good Luck.

Very best regards,

- Jakarta, Indonesia

Q, A, or Comment on THIS thread -or- Start a NEW Thread