-----

Wide Variations in appearance of zinc plated and yellow chromated parts

Q. Does anyone have an explanation for a distinctive color variation between batches of steel that have been zinc plated followed by trivalent yellow chromate, followed by zinc chro-shield? Some are dark yellow with purple tint, others are very light yellowish with slight purple tinting?

Any words of wisdom are welcomed.

Jane Cella- Englewood, NJ USA

December 9, 2009

A. Hi, Jane. 1st question: is this within one batch from one plating shop, or is it a variation between batches plated at different times and places?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

December 10, 2009

A. 1. Variations in color are common from batch to batch.

2. Variations in color may occur if the finisher ran the job on two different lines.

3. Variations will occur because the process does not produce a cosmetic color but rather a protective film and this film will be yellow with blues, purples, etc partially because of the chemistry and partially to simulate the color of hexavalent products.

What is your problem with the finish? Color does not serve as an indicator of corrosion resistance.

process supplier - Great Neck, New York

December 12, 2009

December 10, 2012

Q. Good morning,

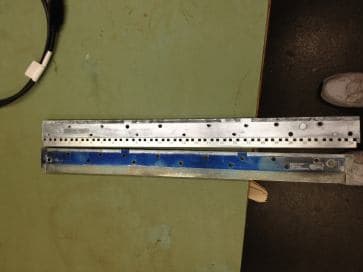

I have received chassis that include two unique card guides made from ZAMAC 3. These parts are supposed to be zinc plated with a clear chromate finish. This most recent shipment had castings with a dark purple color. One of the two parts looks fine. the other is quite stained looking. Both parts are from the same casting supplier and date code. Cross sections clearly show plating presence through the bright and purple areas but the parts look terrible.

I am looking for ideas as to why this would happen and preventive measures.

Thank you for any assistance.

Frank

- Franklin, Massachusetts, USA

A. Hi Frank.

When people speak of 'purple' in chromating they are referring to a pastel iridescent hue which is due to diffraction interference effects. What you have pictured there looks to me like the 'blue layout fluid dye' that machinists apply to steel so they can see their subsequent scribe marks more clearly.

Personally I have never seen zinc plating and chromating look anything remotely like that; I don't think the plating or chromating was responsible for it.

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread