Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Electro-conductive wax to do electroforming

Hello,

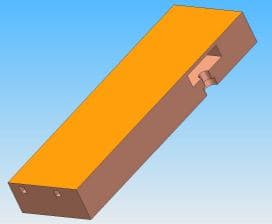

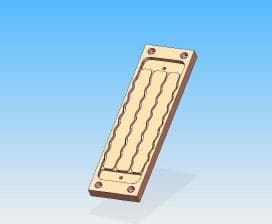

we have to realise a copper mechanical components that has in the interior a serpentine groove for the passage of a cooling gas.

We are looking for an Electro-Conductive WAX or other material that can be use to filler a groove realised in a plate of copper that will beformed with copper, and at the end we will eliminate Electro- conductive WAX.

We will obtain a big plate of copper with the interior serpentine groove.

Anyone can help us?

precision mechanical components - Rome, Italy, EU

September 3, 2009

I think that you are better off to machine both halves with proper fits and then oven braze the two halves together. Electron beam welding is an alternative.

Why not bent hard copper tube with stiffeners added that terminate in mounting brackets.

- Navarre, Florida

September 4, 2009

You can use conventional hard wax, then make it conductive using graphite or copper powder. Get a book or visit a web site which has detailed descriptions for this. Good luck,

G. Marrufo-Mexico

Monterrey, NL, Mexico

September 12, 2009

September 17, 2009

Hello dear James, many thanks for your reply, but unfortunately our client does not accept brazing.

Dear Guillermo, many thanks, yes the solution is a wax and a copper powder layer.

We continue our search.

Kins regards

- Rome, Italy

Alternatively, there are very low melting point alloys (Cerro brand comes to mind). These alloys are totally conductive, mid-hard at room temperature, somewhat brittle but melt at temperatures around or below boiling water. Basically they contain bismuth, tin, indium and lead. G. Marrufo-Mexico

Guillermo MarrufoMonterrey, NL, Mexico

September 17, 2009

Hello Guillermo,

yes we have already made a pieces with CERROBEND Alloy P/N LEGF73C

(melting temperature 80°) but cerrobend do not go away totally, parts of cerrobend penetrate in the copper.

We will perform a new test with a wax specific for dental use, we will cover with a conductive silver layer named Preciano, a product of Heraeus company.

Many thanks

- Rome, Italy

September 22, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread