-----

Electropolishing Cost

Electropolishing is usually an added step after mechanical polishing rather than a stand-alone process. It involves immersing the item in a proper acid mix and connecting it to the positive pole of a DC power supply such that the very outermost surface dissolves into the solution. Because electricity takes the path of least resistance, if the item has asperities/roughness/protrusions sticking up, they draw the current and are the first thing to dissolve.

The main reason for electropolishing is freedom from loose burrs or folded-under areas entrapping contaminants:

Viewed under a microscope the surface after electropolishing will resemble gentle ocean swells whereas a mechanically polished finish resembles a bird's eye view of a farmer's plowed field. No matter how fine an abrasive was used, if you keep turning up the magnification, the clods & furrows are there. For this reason electropolishing is required for some pharmaceutical and dairy components.

An additional advantage of electropolishing is that it serves the same function as "passivation", obviating the need for that processing step. (search the site for "passivation of stainless steel")

Q. Hi, Can anybody tell me roughly what the costs are for electropolishing solutions for stainless steel? Say, if somebody wanted to buy 500 or 1000 litres from a commercial supplier. Just a ballpark number - I know it would depend on the types of acids etc. I was under the impression that they were relatively cheap compared to plating solutions but would like to know.

Thanks, Todd

Scientist - Glasgow, Scotland

February 18, 2025

A. Hi Todd,

Although there are many recipes for electropolishing solutions, one thing most if not all of them have in common is very little water -- so you're buying a lot of highly concentrated acid, which is not cheap.

I see 275 gal of phosphoric acid for $5300, and 275 gal of sulfuric acid for $3800.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thanks for the useful info, Ted. Most helpful!

Thanks for the useful info, Ted. Most helpful!

- Glasgow

IBC = 48" x 40" Intermediate Bulk Container

275 to 330 gallon depending on height.

A. Hello Todd, for the EU I can tell you prices range from 4000 - 8000 for one IBC of electrolyte.

Coming from someone who runs a company that offers electropolishing in Germany.

CEO - Brandenburg

April 16, 2025

⇩ Related postings, oldest first ⇩

Q. Can anyone tell me how electropolishing is priced for sheet metal parts. Is it by metal surface area? General rough dimension of the part? By piece? Etc? What is a reasonable cost?

Charlie Peck- USA

2000

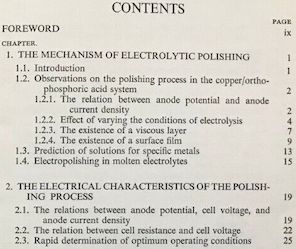

and Chemical Polishing

of Metals in

Research and Industry"

by W.J. Tegart

on eBay or Amazon

or AbeBooks

(affil link)

A. Looked at from a slight distance, electropolishing looks nearly identical to electroplating: unpack the parts, rack them, carry them through a series of open-top tanks, dry them, inspect them, repackage them; deal with the waste, the rectifiers, the chemical makeup, the ventilation, the regulatory agencies, the employees and customers. Which leads to: the cost is very similar to the cost of plating, and labor is the lion's share of the cost.

The shop will quote you basically based on how much labor they think is involved in the steps previously outlined, and how many parts they feel they can get through the line per hour. So "envelope size" may be the unit of measure for cost even through square footage would be what dictates chemical and electrical consumption.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Primarily, the biggest factors in determining the cost to electropolish a part are as follows;

1. Quantity How many pieces per mo/yr.

2. Surface area to be electropolished.

3. Amperage/Minutes required to achieve desired finish.

4. Time (labor) required for racking, pre-processing

5. " " " " " un-racking, post-processing

There could be other factors involved such as fixturing cost, particularly for short or one-time runs.

Phil Sterrett- Cleveland, Ohio USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread