-----

Iridite 14-2 Testing, pH Control & Maintenance

Quickstart:

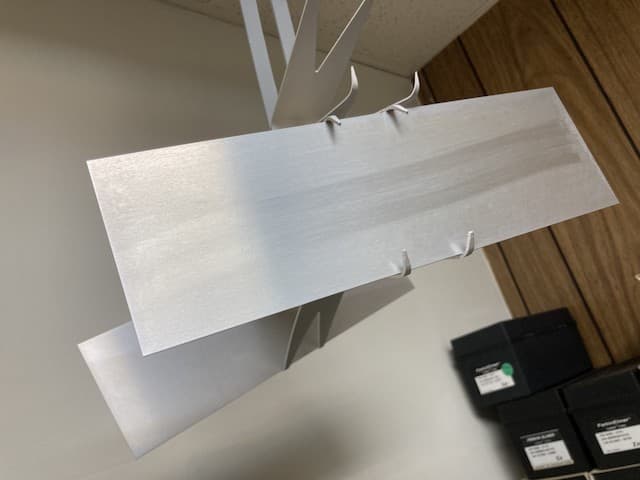

Aluminum is often 'chromate conversion coated' as a corrosion resistant final finish or as a pretreatment for painting or powder coating. The process actually involves many steps, usually including alkaline cleaning, etching, deox/desmut, the chromate conversion step per se, and water rinses between each step.

MIL-C-5541 / MIL-DTL-5541 / MIL PRF-5541 is the most commonly cited spec. "Alodine" and "Iridite" are proprietary trade names of the suppliers of the process chemistry. In the USA "Chem film" is an often used slang term for the process.

![]()

Q. Hello -

I am having trouble with my testing procedure for MacDermid's Iridite 14 - 2. I am trying to test the concentration using their procedure. I have no problem with the testing - BUT the formula has me confused.... It is as follows

m/L sodium sodium thiosulphate

⇦ on

eBay

or

Amazon [affil link]

x *N x 0.81 = Iridite 14-2 oz/gal

* N is exact normality of sodium thiosulphate

That is my problem... Why not tell me the normality of sodium thiosulphate ? Does it change ?

Any help with what the normality of sodium thiosulphate is or another formula would be appreciated.

Thanks,

PM Industries - Springdale, Arkansas

2006

The vendor will normally recommend a normality and you can literally buy premade solution from a chemical supply house in a number of normalities. For the best results, use the one that is suggested.

James Watts- Navarre, Florida

First of two simultaneous responses --

Sodium thiosulphate can be prepared or purchased in different concentrations.

If preparing, you will need to standardize against a known concentration of potassium dichromate (also can prepare or buy). Also, add a bit of AR grade sodium bicarbonate (2g/L) as preservative.

As you seem not a chemist, I suggest purchasing certified 0.1N sodium thiosulphate from a chemical supplier such as Fisher Scientific or Spectrum Chemicals. It readily spoils (Thiobacillus food), which reduces the normality and messes up the analysis. So, don't purchase large containers, open a fresh 1 Liter bottle each month, don't return unused reagent to the bottle, keep tightly capped, and store in the dark.

- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

2006

Second of two simultaneous responses -- 2006

John,

sodium thiosulphate

⇦ on

eBay

or

Amazon [affil link]

is available in a number of normality concentrations. The idea of the generalised formula is to allow for the use of any reasonable concentration. Usually you would use 0.1N, but I have seen people use 0.2N and 1N.

The important thing is to have a concentration low enough to allow a reasonable size titration value.

Aerospace - Yeovil, Somerset, UK

My company is running a small conversion coat system to clean custom sheet metal parts. I have been challenged to make sure our system is yielding the result for which the system is intended, and if they are not, then to find out what processes should be put implemented to maintain an adequate system. We currently test PH and Temperature. I was hoping there was an alternative or short-cut to a full laboratory titration. Are there any simple kit, manuals or training videos out there? I could really use some help.

Jason BeasleyOEM -Chromate Conversion Finisher - Keystone Hts, Florida, USA

December 1, 2008

First of two simultaneous responses --

Unless you are processing a huge amount of material, testing once a week by titration should be adequate, in addition to the testing that you are doing now. Contact tech services of the company providing your chemicals for their recommended testing. Typically this will be for chromate as they do not want to talk about the other materials in their product, for good reasons.

You really need to be doing salt spray testing of the parts or more probably on test panels per the appropriate spec. Note that tiny cabinets do not work as well as medium size cabinets. At least one cabinet maker will not guarentee the results from their small cabinets. The problem is with the fog generator and the distribution of the material and still meet the spec minimums for amount. Running a salt spray cabinet looks simple, but it requires routine maintenance to work well.

- Navarre, Florida

December 3, 2008

Second of two simultaneous responses -- December 3, 2008

You must control concentration, your vendor should furnish the titration instructions, if not, I can arrange for you a product that comes with titration instructions and telephone service (by me).

Yes, control pH also. lower with nitric acid, raise with ammonium hydroxide.

Clean, etch, and deox properly, do not drag contaminants into the chromate. Moderate air agitation. Normal; room temp, however, at least one vendor calls for heat to 90 or 95 F.

Chlorides over 50 ppm (tap water) is lethal; make-up with deionized water, especially in Florida.

adv.

Call me for more consultation, no charge for telephone service.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. Hello,

Does anyone have any experience using Iridite 14-2 for their yellow chem film baths? We have recently started using it and are having a lot of trouble maintaining the pH of the solution. The TDS recommends using 42 Be Nitric Acid to lower the pH, but even after multiple additions, the pH will not stay down in the specified range. If anyone has had a similar experience and has any advice, that would be greatly appreciated. Thanks!

Zander Naes

- Denver Colorado

July 12, 2022

A. Hi Zander,

I just wrote out a long response and accidentally deleted it...

Short version:

I run 14-2. In almost 10 years I have NEVER adjusted the pH. Not once. I control my bath by annual ~40%ish decants.

Make sure you have a pH 1 buffer to calculate offset. Are your measurements correct?

Are you filtering your bath? DON'T. I typed out why but ... ugh.

When is the last time you did a 25-75% decant?

Have you checked for pinholes in your steam lines.

And if you are freaked out over pH because of test failures ... look skeptically at your deox. Is it strong? Fresh? Free of grease and silicon?

Is your line tech angry about anything? Ask them how they feel about their response time for Class 3. The bath pH has a wide range. But the ideal coating depends on so much more. And a good line tech will start grumbling the moment something ain't right!

Rachel Mackintosh

Lab Rat / WWTF - Greenfield MA

October 10, 2022

A. Mackintosh has told you all you need to know except for one thing, what is the pH of the rinse water you are dragging into the 14-2?

Robert H Probert

Robert H Probert Technical Services

![]()

Garner, North Carolina

Q. Rachel,

Thank you for your response. We just switched to Iridite 14-2 a few weeks ago so we have not needed to decant the tank yet. Would you mind sharing your operating parameters (pH, concentration, immersion time, etc) for your Iridite tank? We have been having some 2024 salt spray failures so I want to double check our parameters with someone who is familiar with the product. We are within the ranges given on the TDS, but I want to try to narrow these a bit more. Any help is greatly appreciated.

Best,

Zander Naes [returning]

- Denver, Colorado

October 17, 2022

A. Hi Zander!

I actually really trust the manufacturer data sheet. If you're staying towards the middle of their concentration / pH brain teaser, you're fine.

One thing I've been told to start up a new tank, is a small amount of sodium chloride (lab, not cafeteria). I made my last from-scratch tank this way after a steam line disaster that still keeps me up at night. I wish i could remember if this was from a macdermid chemist or an industry connection, nor what the amount was offhand, though im sure ive got it written somewhere. It sounds counterintuitive, right?

But the 2024 salt spray problem goes beyond the iridite tank. If i had a quarter for every full-sheet 3x10 sheared 3x10x.032 2024 that i got with massive surface defects, i could wash a load of laundry! Take a few of those panels and run them through tyII or II.5 anodize and ask the line tech how they were after etch, hard to deox, looked funky, just didn't sit quite right. Ive seen a lot with weird longitudinal granular inclusions that will pass salt spray on any type of anodizing, but absolutely crash in chemfilm salt fog.

Your best bet here IMVHO is to look around for alternate coupon sources, and at the same time also try to optimize your deox to be very clean. If you can filter it, that will save you more money in tank dumps and test failures than you will spend in the pumps. I believe the DeOx is the most important tank in a plating shop.

There is a place somewhere in Texas that offers DA sanded and ASTM spec solvent cleaned test panels that mimic an actual part freshly machined and degreased, which is what we all see for parts anyway. So that's arguably the ideal substrate to test on as well. I was DA sanding mine with AlOx (trust me) abrasive to break the mill finish previously, its definitely worth exposing actual true substrate so you don't have to etch so long all the hard to desmut junk gets brought to the surface.

Clean DeOx, clean panels, don-'t over-rinse after the Iridite unless doing that weird colorless spec, no filtering, maybe toss a couple aluminum rack bolts in to add to the voodoo sludge lol. Half kidding.

Half.

Take a sample now and test for chromium, iron, silicon, copper, and barium. Set it aside as your "fresh" tank. Cr and Ba will fall, Fe Cu and Si will rise. Keep an eye on those levels, and in a couple years of quarterly data set against salt spray results, you will be able to predict scheduled decants.

Good luck!

Sorry for the late response. Audit season.

Rachel Mackintosh

Lab Rat / WWTF - Greenfield MA

|

|

Q. Rachel,

Is this because there is still some residual smut? Is there another way to verify that a panel is smut-free? As always, your help is greatly appreciated. |

⇩ Related postings, oldest first ⇩

for Shops, Specifiers & Engineers

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

Q. TRYING TO GET A HIGHER pH IN THE BATH, I POURED SOME 50% caustic soda ⇦liquid caustic soda in bulk on

Amazon [affil link]

UNIFORMLY AROUND THE TANK WITH AGITATION ON IT,THE pH AT BEGINNING WAS 1.49 AND I DESIRE A 1.8 AND I DID GET 1.8 pH BUT THE IRIDITE DOES NOT ATTACH TO ALUMINUM ANYMORE. I'M DESPERATE FOR A SOLUTION BEFORE I DUMP THIS SOLUTION. IF AN ALUMINUM RACK INTO IRIDITE 14-2 TANK IS TOUCHING STEEL/304 CAN BE CAUSING THIS PROBLEM?

ELVIS INDARTE

CHEMIST/PLATER/ANODIZER - PATERSON, New Jersey, USA

July 19, 2009

|

A. Mega too strong a hydroxide to raise the pH because it will precipitate some of the chrome out and it takes forever to come back into solution. I suspect that it adversely affects some of the proprietary stuff in the solution also. A. I do not care what the supplier data sheet says, raise the pH with ammonium hydroxide NOT caustic! I suspect your pH measurement is not accurate, that low range is difficult, especially with single jointed probes. Dip out 5 gallons, raise and lower the pH in "apparent" increments of 0.3 until you find the right pH for your particular temperature and concentration. And be sure the deox is working. |

A. I know this is a bit of an old thread but I have a couple things to add.

First, Robert is dead on the money about the NaOH being a less than ideal pH adjuster. There's already sodium in the tank in the form of sodium silicofluoride, but that doesn't mean that it can take a whole bunch more without throwing the chemistry out of whack.

If you are running Iridite you will ABSOLUTELY need to have a bottle of pH 1.0 buffer solution to check your accuracy. Calibrate your meter as usual with the two-point 7 & 4 buffers, then rinse the probe well and stick it in a small beaker [beakers on

eBay

or

Amazon [affil link] of 1.0 buffer. If you can find 2.0 buffer, that will also work for this application. Give it some time to equilibrate. When the reading stabilizes, record the value. If your meter is anything like mine, it will not hit 1.0 on a two point calibration. So if your Buffer 1 reading is 1.2, apply a correction factor of 0.2 to your tank reading.

Another thing to note is that the correct pH of the solution is (according to the manufacturer) concentration dependent. So at 0.75 oz/gal the given target is 1.75. At 1 it is 1.6. At 1.25 it is 1.45. Do a titration to find your true concentration before you set the pH. Now, this is information directly from the tech sheet. I have had a consultant suggest a target of .85 oz/gal and pH 1.85, fresh from stock, without the addition of any old tank 'heel' or copper or chloride, just a little scrap aluminum to pre-condition the bath. At that combination the coverage and color is excellent. That was run as a bucket test which is a great way to evaluate your mix without committing to a whole tank.

Your stainless tank is not causing you any issues. Stainless steel tanks are fine for this material. There's ferrocyanide in the formulation. That being said, our tank has been in use over a decade and rather than pitting/etching into the metal, the solution tends to adhere and scale up on it. You'll see greenish residue which is reduced chromium and possibly some copper. The rack sitting on the lip of the tank aluminum-to-steel is fine.

Lastly, the reason you add DILUTE base rather than 50% is actually not to avoid precipitating out the chromium. In a hexavalent state, Cr+ stays put. In fact, a great way to get impurities out of a dichromate seal tank is to raise the pH to 8, drop the aluminum, decant the supernate, ship off the sludge, and return the seal to the bath. You'd see that the supernate naturally goes back down below neutral if you haven't added too much hydroxide, because the -OH is now stuck to the +Al in the bottom of the tank! The +Cr is still in solution. You would have to reduce it to tri with something like a permanganate to get it to form an insoluble hydroxide, which would drop out of solution as pH is raised.

You DO need to be concerned about messing with the activators, though! A large percentage of the Iridite is made up of a Barium salt, and Barium readily forms whitish hydroxides. You'll see almost neon-orange-Tang looking clouds where you pour in your pH-up. Avoid that by diluting it A LOT! I can't find a pH solubility curve for Ba(OH)2 but this would be my first concern. And regardless of pH, its solubility is MUCH greater in very hot solutions. Iridite is not all that hot. Or at least it shouldn't be!

Last, I can't emphasize enough the importance of testing your deoxidizer. Do a white glove test on parts coming out of it. Or use a white cotton towel. If you see ANY discoloration, increase your time, agitation, or concentration. Be sure you are having the aluminum content tested regularly and stay below the manufacturer's upper limit. Deox by its very nature (peroxides or persulphates) is unstable and is rapidly used up under workload and also air sparging will deactivate it slightly. Be sure you are titrating it a couple times a week for redox and once for acid content. Daily maintenance adds are advisable for a busy shop.

Anyway I hope you solved your problem and that this is helpful for future platers! :)

Rachel Mackintosh

Lab Rat / WWTF - Greenfield MA

April 11, 2016

Q, A, or Comment on THIS thread -or- Start a NEW Thread