Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Yellow Stains on Electroless Nickel Plating

Q. The parts come out from electroless nickel looks ok but follow-up ultrasound rinse part convert to yellow, why?

How we can correct yellow parts?

Popatbhai B. Patel

electroplating consultant - Roseville, Michigan

March 20, 2024

⇩ Related postings, oldest first ⇩

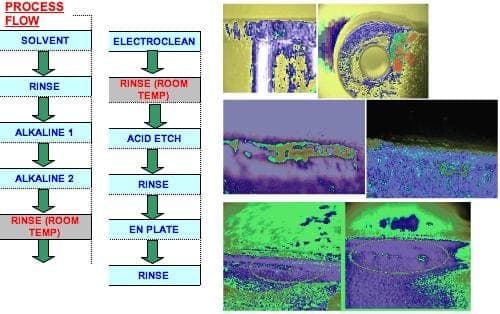

Q. We are doing Hi-Phos EN coating 13~15µm thickness on Fe-based Computer hard disc components. After EN coating we are observing yellow color stains on the rough edges or on the micro cracks of the material. When we see under scope it looks like a yellowish red color bleeding around the stain. These stains can ot be seen by naked eye and all the reliability tests like Humidity test, Ferroxyl test and Nitric acid tests, etc. Can anyone suggest any possible causes for these yellow stains?

plating shop employee - Singapore

June 24, 2009

A. This staining is oxidation, when micro cracks and roughness are present in EN plate, is better to treat with ultra sonic cleaner before electro cleaning.

Franz R Wagner

- Blumenau SC Brazil

A. Never go from an acid solution to the EN, even though you rinse in between. Always use an alkaline dip in between for steel parts.

Another possibility: you need a post dip after EN.

The best one is a diluted chromic solution

Sara Michaeli

Tel-Aviv-Yafo, Israel

July 22, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread