Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

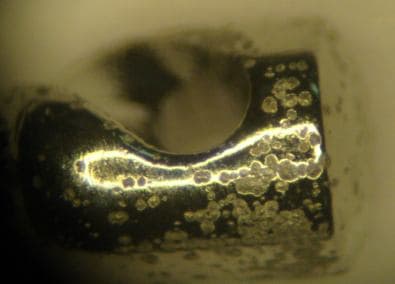

Electropolishing Finishing Defects Pimple like surface

May 18, 2009

I am a Sr. manufacturing engineer for a medical device company in the S.F Bay area seeking an answer to a problem on one of our components. A 17-4 H900 stainless steel part about .046 diameter x .5 inches long contain pimple-like bumps concentrated in a random pattern on one end of the part only. The electropolisher we use has never seen this condition in his experience and my research is inconclusive. This small parts are individually clamped and racked on the opposite end of the defect.

30X magnification:

Does anyone know what may cause this problem? We want to be certain it is not a contaminant added to the part but just a side affect to the 17-4 material during the electropolishing process. I don't know the parameters used by the electropolisher but I do know they are cleaned before leaving our facility and again by the electropolisher.

Andrew delosSantosManufacturer - Fremont, California, USA

First of two simultaneous responses -- May 22, 2009

Hi,

It looks to me what I call "salting-out". This occurs when when the metal dissolving from the component forms an insoluble metal salt because saturation is reached. Having been initialised,the deposit grows. As it does so, the metal underneath the deposit ceases the dissolve and so becomes above the level of the surrounding metal and gives the pimples which you describe. The metal salt can be amorphous or crystalline. It may dissolve during rinsing so just leaving a metal surface.

The factors which affect the formation are

1) dissolved metal in the bath is too high

2) water content too low (can be checked by specific gravity)

3) current density too high

4) temperature too low

5) insufficient agitation

Harry

Harry Parkes

- Birmingham, UK

Second of two simultaneous responses --

Two-dimensional photos can be misleading, but it doesn't look at all like etching to me -- it looks like some kind of a corrosion

"growth". Maybe Andromeda Strain :-)

I'm totally mystified and look forward to hearing someone advance an idea.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

May 22, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread