Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Can we nickel strike on top of Nano Metal Thin Film Coating to improve adhesion?

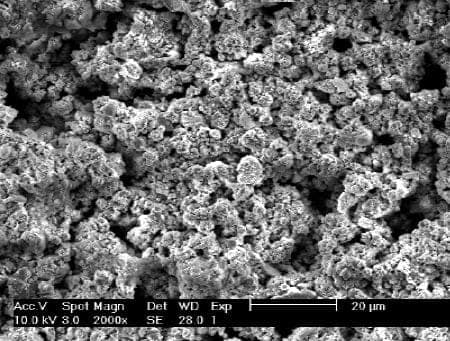

I am looking to coat some 316L stainless steel electrodes with nano sized metal spherical particles in an effort to achieve a very high specific surface area for increased electrical conductivity. My challenge is adhesion so I'm hoping someone could tell me if after the spherical particle deposition is applied (and solvents baked out leaving a very light trace of a acrylic binder) if a very short strike of a 1/2 minute (more or less) of either electroless Ni or electroplated Ni would structurally bond the high surface area of spherical nano particles to the substrate without adversely depleting the high surface area.

Engineer - Bothell, Washington, USA

April 28, 2009

20% HCl, rinse, and plate in a woods nickel strike or low pH sulfamate nickel strike. Rinse quickly and plate in a watts or sulfamate nickel to build a little thickness. Nickel strike plating solutions result in very thin deposits, for bonding I think you need 40-100 micro inches. 0.00004" to 0.0001") or so. The low pH strike is necessary to re-activate the SS for good adhesion.

Don Baudrand

Consultant - Poulsbo, Washington

(Don is co-author of "Plating on Plastics" [on Amazon or AbeBooks affil links]

and "Plating ABS Plastics" [on Amazon or eBay or AbeBooks affil links])

April 30, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread