Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Best cooling system for hard anodizing?

Q. We have an anodizing facility for decorative anodizing. We need to build a hard anodizing facility.

Questions:

(1) What temperature is normally applied for hard anodizing process?

(2) What solution composition is used for the process?

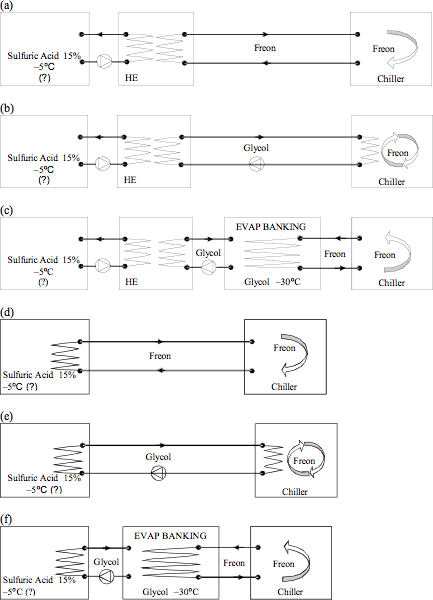

(3) What kind of cooling system appropriate for the process? (Should we need to use a heat exchanger outside the anodizing tank, or directly in the anodizing tank?; Do we need to use glycol in the system, or without glycol?)

Thank you very much

M. Bahri

Plating shop employee - Bandung, Jawa Barat, Indonesia

November 2, 2008

A. Hi, Moh. The usual temperature for hard anodizing is about -2 deg. C. 10 percent by volume H2SO4 is customary although some proprietary addition agents have been found useful.

I have seen all of the cooling arrangements that you illustrate, including "d", but I don't like that one at all. Too much likelihood of refrigerant leak!

"e" and "f" are okay, but in today's age of higher technology and engineered solutions, I prefer to see external heat exchangers when dealing with the very cold temperature of hard anodizing and its refrigerants.

In arrangement "c" you have "Evap. Banking". If this is what I would call a "Chilled Water Storage Tank", I think that's my preferred arrangement.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

November 10, 2008

Q. I AM AT WORK ON OPERATION A NEW ANODIZING LINE. THERE ARE DIFFERENT TANKS, MORE THAN 10, WHICH ENABLE US TO CHOOSE ANY PROPER PROCEDURE. BUT THE BIG PROBLEM IS THE CHILLING SYSTEM OF THE ANODIZING TANK; IT IS DIRECT CHILLING WITH FREON AND THE TUBING IS MADE OF ALUMINIUM SO WE SUFFER FROM LEAKAGE BECAUSE OF CORROSION.

DR.KAREEM ALSAMURAEEPROCESS SUPERVISOR - IRAQ-BAGHDAD

July 8, 2010

A. Hi, Dr. Alsamuraee. As you can see, we appended your inquiry to a previous thread which you may find helpful. But if you must stay with running freon through coils in the anodizing tank, I think you will find that titanium tubing offers much better life expectancy. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July , 2010

Q, A, or Comment on THIS thread -or- Start a NEW Thread