Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

Thread 496/41

Field restoration of stainless steel #4 brush finish damaged by transit

August 11, 2008

I am looking for advise on how to restore a #4 brush finish on the door of an electrical control panel made of 304 stainless.

We made the mistake of shipping these units without any protective barrier between the styrofoam sheet packing material and the stainless cabinet. There must have been some weight on top of the package during transport across country the weight and vibration created an ugly appearance ruining the #4 brush finish. The finish now looks like the bumpy surface of styrofoam sheeting.

This was proven by doing an accelerated test using a vibratory sander and a piece of styrofoam. Within 5 minutes we had minor damage to the finish very similar to the damage created during shipment.

Does anyone have any ideas on how to restore that finish?

FABRICATOR OEM - HAMBURG, Pennsylvania, USA

publicly reply to JOE SMITH

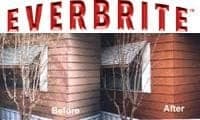

Hi, Joe. Try wetting the stainless steel and seeing what it looks like. If the appearance is satisfactory when wet, meaning that the dull burnishing is thin, often a clear coat like

Everbrite [a finishing.com supporting advertiser] can make it right. If it doesn't look good wet, I think you need to take the doors off and have someone local redo them with a Timesaver (large belt sanding machine).

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

August 12, 2008

publicly reply to Ted Mooney

Q, A, or Comment on THIS thread -or- Start a NEW Thread