Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Chloride & Chlorine corrosion of stainless steel: use type 2205 duplex?

Q. Hello,

I have recently started a job with a company who manufactures coagulants. We might use one of our products PAC Poly Aluminum Chloride to treat water that runs through a cooling tower. What I need to no is if any of the chlorides come in contact with the stainless steal, what will happen? Is there an IMAC for stainless steal 304?

If you can share your knowledge with me it will be well appreciated.

Thanks.

Tylor HaugerStudent - Valhalla centre, Alberta, Canada

2004

2004

A. The common grades of stainless (such as 304 and 316) certainly have their place, but that place is well down the ranking of corrosion-resistance. They're pretty ordinary materials by today's standards.

You may need to look at 2205 or 2507 grades of stainless for your type of service.

Bill Reynolds [deceased]

consultant metallurgist - Ballarat, Victoria, Australia

We sadly relate the news that Bill passed away on Jan. 29, 2010.

A. Any chlorides will adversely affect stainless steel. It depends on the concentration, temperature and frequency of exposure as to how long the 304 stainless can hold up to this. If you can go to a non-chloride product you are better off.

Lee Kremer

Stellar Solutions, Inc.

McHenry, Illinois

2004

Q. We use process water from our wells in our factory. The water contains chlorides and we chlorinate the water for disinfection purposes. We then heat the water to 90 °C. We find that our 316 stainless steel pipes are pitting and corroding. What can we do to protect the pipework? I really appreciate any help you can give.

Tom Rowanenvironmental consultant -Meath, Ireland

July 5, 2008

A. If chlorides are your only problem, running the water thru granulated activated carbon with a reasonable residence time will remove most of it. Next in price, you could try reverse osmosis (RO). The correct deionization system (DI) can selectively remove most anything from water, it is however expensive to operate and requires appropriate attention to the operation and the regeneration cycle to prevent unwanted failures and down time. There is an outside chance that ultra filtration might work, but it also is not cheap.

Water softening will not help you.

- Navarre, Florida

July 10, 2008

A. Unfortunately, stainless steel is stain"less" not stain"free".

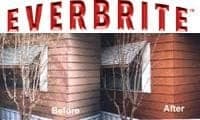

adv.

ProtectaClear is a clear protective coating that has resins that are highly resistant to salts and chlorines, has excellent adhesion on stainless steel and may be able to solve your problem.

Everbrite Coatings

Rancho Cordova, California

July 24, 2008

A. You can try electropolishing the stainless to increase the passivity and corrosion resistance by removing all surface impurities and contamination. This will leave a very pure highly corrosive resistance surface. It should increase the service time.

If the parts still do end up corroding. You may have to look into duplex 2205 stainless (made for chloride environments)

electropolishing shop - North Vancouver, British Columbia, Canada

September 21, 2009

Q. We have a heat exchanger with duplex 2205 for both shell and tubes; tubes fail frequently while the shell has not shown any failures since inception. The chlorides are in the range of 80 ppm on process side. Process is on shell side, with cooling water on tube side. Not able to trace the root cause for tube failures. Can somebody support in this regard?

SANJAY B.- Mumbai, India

November 20, 2015

Q, A, or Comment on THIS thread -or- Start a NEW Thread