Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Chromicoat L25 won't plate to 2024-T3 Aluminum

Q. My name is Edmundo and I supervise a chromate conversion process line. We currently use Chemetall Oakite Chromicoat L25 for class 3 and class 1a plating of aluminum per MIL-C-5541. We are experiencing problems with this chemical not adhering to 2024-T3 aluminum. Our bath stages consist of Oakite 33 (a liquid acidic compound designed for removing grease and shop oils), Oakite 360L (a highly alkaline etchant), Oakite 34L (deoxidizer), and Chromicoat L25 (a liquid chromate conversion coating). The operating ranges for the L25 tank are as follows: pH 1.6 - 2.0, concentration 3% - 6%, and temperature of 119.

Edmundo Luis AguilarSupervisor - Des Plains, Illinois, USA

June 25, 2008

A. We suspect your pH measurement is slightly out of whack.

Dip out two buckets, then however you measure pH, raise the pH in one bucket by 0.3 with ammonium hydroxide, lower the pH in the other bucket with nitric acid, run three panels down the line, one in the tank, and one in each bucket. Observe the results.

If the above is no difference, then go back to the deox, make up a new solution in a bucket, make a 25% add to another bucket, run three panels, let us know what happens.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

June 27, 2008

A. Edmundo

Have you always used the L25?

Have you been able to achieve favorable results on 2024-T3 before.

If yes to both, look for that which has changed (or could change) in your process... rack material, galvanic currents, aging chemistry, water quality, new chemical lot addition, new Al source.

If the L25 is new to your process, verify you can process 2024 by mechanically cleaning a coupon and immediately immersing in the L25 for your standard duration. If the coupons coats, start adding one of your standard steps and repeat until you find the problem.

- Colorado Springs, Colorado

June 28, 2008

A. Try skipping the etching process and use a little longer deox time. You may find it useful to have a sample analyzed by Oakite. You may find your chemistry is out of balance

Larry Rubin- Spokane, Washington

July 8, 2008

Chromate Conversion Coatings Free of Hydrofluoric Acid?

Q. Chromicoat L25 contains hydrofluoric acid. Is there an alternative product without HF but still meets MIL-DTL-5541, Class 1A and Class 3?

Michelle Gaitherenvironmental assistance provider - Seattle, Washington, USA

April 29, 2016

A. Hi Michelle,

Look up the Qualified Product Database (QPD) on the DoD Assist Quicksearch for MIL-DTL-81706

[⇦ this spec on DLA]

. These are all products qualified to be used to produce coatings in accordance with MIL-DTL-5541

[⇦ this spec on DLA]. From that list look at the Material Safety Data Sheet (MSDS) for information about the contents of the solution or ask the manufacturer of the product you are considering whether it contains HF.

Aerospace - Yeovil, Somerset, UK

May 5, 2016

A. You need to know the concentration of the HF in the product to really determine how serious a factor it is. I have used concentrated HF and I have the greatest respect for it. However a 0.1N solution is pretty much a pussy cat with the minimal amount of safety gear.

Your product starts with an L so I assume that it is a liquid. Note that they probably sell a similar product that is a granule. Therefore it will have a fluoride like sodium or potassium fluoride

⇦ this on

Amazon [affil links]

. Does this scare you?? If not, why does it as HF scare you?

Environmentally, the chrome6 is more of a hazard.

This is my worker bee opinion.

- Navarre, Florida

May 10, 2016

![]() Great advice (check the concentration in the product). The concern is hydrofluoric acid can cause severe chemical burn, but when skin receives the exposure, the burn/damage doesn't show up until many hours later.

Great advice (check the concentration in the product). The concern is hydrofluoric acid can cause severe chemical burn, but when skin receives the exposure, the burn/damage doesn't show up until many hours later.

from Wikipedia: In the body, hydrofluoric acid reacts with the ubiquitous biologically important ions Ca2+ and Mg2+. Formation of insoluble calcium fluoride is proposed as the etiology for both precipitous fall in serum calcium and the severe pain associated with tissue toxicity. In some cases, exposures can lead to hypocalcemia.

I am researching this for a company. I presume, due to the chrome, that PPE is used, so skin contact may not be very likely anyway.

environmental assistance provider - Seattle, Washington, USA

May 11, 2016

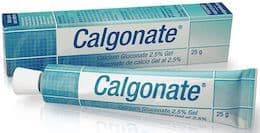

Never use HF anywhere unless trained!

If you do, you MUST have the antidote gel on hand for instant use!

Calcium Gluconate

for HF acid burns

on eBay or

Amazon

(affil links)

A. A true HF burn is indeed very serious. Unlike strong acids, it tends not to have much pain associated with it until it has done damage.

You need to take a look at the first aid requirements. After normal flushing, it needs to have an injection of a material under the burn. I do not remember what it is, but it requires a prescription. It took a good bit of begging for the local ER to keep it on hand and to try to get them to know the appropriate treatment.

- Navarre, Florida

May 12, 2016

A. It's calcium gluconate. It deactivates the fluoride by precipiting the F-.

Dave Wichern

Consultant - The Bronx, New York

May 14, 2016

A. You can get tubes of Ca gluconate paste from Grainger under the trade name 'Calgonate'. It is intended to be used externally IMMEDIATELY upon dermal exposure to HF. The injectable stuff requires a trip to the ER. Use the paste to buy time while you're on your way to the parking lot...

IMVHO, if you're messing with concentrated HF, it is essential to keep a couple NON EXPIRED tubes in the first aid kit and check in with your nearest urgent care facility to make sure they are ready to deal with an exposure.

As an aside, you're just as likely to have HF in your desmut or satin mask... Even if it comes as a powder, check the MSDS for Fluoride salts.

Rachel Mackintosh

lab rat - Greenfield, Vermont

June 17, 2016

Q, A, or Comment on THIS thread -or- Start a NEW Thread