Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Passivating stainless steel to prevent EN plating from depositing on it

Hello,

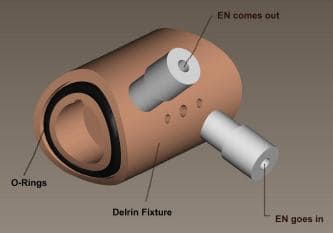

I'm trying to use custom designed stainless steel fixture for electroless nickel plating in specialized petroleum drill strings. I have used delrin before, but I have seen a lot of warping due to high temperature. Is there a way to passivate the SS fixture such that it doesn't get nickel deposition during plating? Any advise would be greatly appreciated.

Engineer - Provo, Utah, USA

May 8, 2008

|

Can you use plastisol for the heavy parts of the jig? If the contacts can not be heavy coated, you might try a teflon coating, but expect to have the contacts (removable) needing re coating from time to time. There are some vinyl coating that work fairly well also. James Watts- Navarre, Florida May 9, 2008 Immersion in nitric acid will passivate SS but the effect will not last indefinitely. It will become active after some time needing re-passivation. Guillermo MarrufoMonterrey, NL, Mexico May 9, 2008 |

Thank you for your responses.

I would like to use some kind of plastic for the fixture, but one of my prototypes which was made of delrin got heavily warped. How good is TEFLON against acid and other chemicals?

- Provo, UT

May 12, 2008

May 13, 2008

Delrin is good stuff, but it is not meant to carry much of a weight load. Plastisol is the coating of choice by most rack manufacturers as it is tough when properly cured and can be put on in coats if thickness is required. But this is over an appropriate metal such as copper, aluminum or brass.

Teflon is impervious to nearly everything if applied properly and thick enough. It is more costly, but can be applied significantly thinner than plastisol which makes it great for attachment points. It does not have the wear (abuse) ability that plastisol has because it is relatively thin.

Have you talked to a reputable rack Mfg.?

- Navarre, Florida

Hi James,

I'd rather have the complete fixture made of TEFLON than just having a coating on it. My inclination to using stainless steel for the fixture was my previous prototypes which were made of Delrin warped heavily under thermal stress. TEFLON seems more inert to chemicals and temperature compared to Delrin. My question is, are plastics as susceptible to electroless nickel plating as metals are? My experience is I've never seen any visual nickel deposits on Delrin. Am I right here?

- Provo, Utah

May 15, 2008

It would help if I / we knew what you were plating and how many at a time.

Teflon is very expensive and is subject to cold creep and bending more than filled Delrin is. Bad choice.

Unless the part/s is/are very light, no plastic will work very well.

I like a challenge, so, send us a picture of the part with dimensions and weight and a second picture of a current rack with a yard stick along side of it so we can have a good idea of size and shape.

I think that I have used nearly every plastic and coating that has ever been used in plating.

Since you are leaning to an all plastic fixture, I assume that you are not doing an electroclean or an anodic etch of the parts.

- Navarre, Florida

May 15, 2008

Hello James,

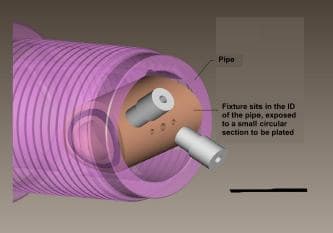

Please see the attached picture of what I am plating and what I'm using as a fixture (currently). I am doing EN plating on the inside of a 2.9" diameter pipe. The heater is wrapped around the OD of the pipe and the fixture fits in the pipe. The EN process includes surface cleaning (alkali), etching and finally plating. I have used delrin in the past and it has worked really well for me. I'm trying TEFLON because it has better resistance against both heat (temp goes up to 90C) and chemicals. Let me know what you think.

Thanks,

Prabesh Lohani [returning]- Provo, Utah

May 22, 2008

Q, A, or Comment on THIS thread -or- Start a NEW Thread