-----

After passivation and drying hypotubes we are left with a green contaminant

We have come across this problem recently. I'm an engineer in the passivation pickling department of a medical device company. we have a cut spiral on one end of a hypotube and after drying we discovered a green residue. I was told that this is dried pickle not rinsed properly through the crevices of the laser cut spiral. can we help the rinse DI water prevent this can you suggest some preventive action.

Regards,

medical device company - Ireland

2007

Better rinsing can be better water, more water, warm water, longer contact time and better agitation. For very tiny crevices, you will probably have to go to ultrasonics in your rinses. That is rather expensive, so you might want to lab test the other options first.

James Watts- Navarre, Florida

2007

You will not rinse residues from a hypodermic tube with ultrasonics. All it does is to vibrate the liquid in the tube.

A simple answer would be to use a hypodermic syringe to force a few ml of DI water down the tube. 1 ml compared with the internal volume of the tube constitutes a vast amount of rinsing and takes a few seconds.

Which of the famous forty shades of Irish green ?

Geoff Smith

Hampshire, England

2007

Hi lads

thanks for the info. Just to let you know, we have ultra sonic baths and all. the ID of the tube does get fully rinsed during the cycle. The problem only arises at the beginning of the spiral cut. This is where the water first escapes from the ID and does not continue down the ID of the tube but escapes naturally down the OD of the of the tube.

- Galway

2007

Use HOT WATER and DRY the part with AIR ASAP.

Jose Castellanos- Minneapolis, MN, USA

January 3, 2008

Q. Hello, I am in the medical machining industry. I am struggling to clean the ID's of a 304 SST Hypotube that has been laser cut in a spiral pattern on one end. The requirement for assuring a "clean" ID has been set forth for me as, running a SST mandrel through the ID and wiping it onto a clean lint free towel. A clean wipe with zero residue is considered a pass. I have tried everything to get this to work including but not limited to a nitric/HF etch of the laser cut followed by a so far up to 8 hour passivation in 20% nitric. Followed by a 20 min flowing DI rinse. I have also tried 180 degree potassium hydroxide ultrasonic clean. I do not believe the test method is possible due to the running of a SST mandrel through the SST tube is going to give a residue every time due to the metal on metal contact. Any suggestions or feedback would be greatly appreciated.

Eric HennenChemical engineer - Brooklyn Park, Minnesota, USA

December 21, 2011

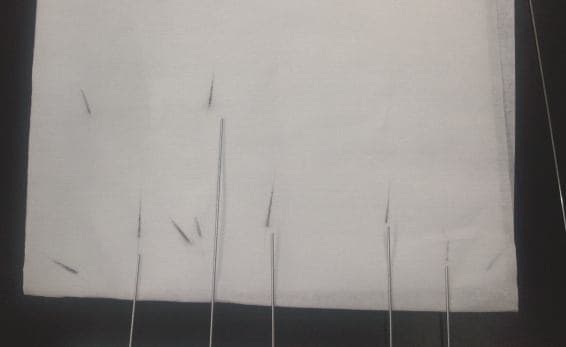

It appears to be a smut, residue. I don't believe that I am having a cleaning issue, the parts appear clean through a visual inspection, however during the mandrel/wipe test a grey material is evident upon every attempt. I will add a picture to help explain my dilemma:

- Brooklyn Park, Minnesota, USA

January 18, 2012

Your method of etching/passivation with nitric acid cause carbon burning on the inner surface of the tubes. Switch to a mild oxide removal method to avoid this problem. We use it for cleaning/oxide removal of stainless stents before electropolishing.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

January 19, 2012

The Nitric/HF will leave a metallic smut on the surface. Since your test is a mechanical scrubbing, is it possible to scrub the ID with a brush and a mild alkaline cleaner?

If mechanical cleaning of the ID is not possible, you may be able to clean the ID with a flow of turbulent cleaning solution or water. A flow rate of ~10 or more feet per second should generate enough turbulence to scrub the ID.

Lyle Kirman

consultant - Cleveland Heights, Ohio

January 24, 2012

To the last point. If you used water with an abrasive suspended (some type of media).

The part could be fixtured and high pressure water blasted through the tubes. If your aim is to remove loose residue on the ID this should work.

- Ireland

January 25, 2012

Eric,

I once was given some small tubes similar to yours that had been laser cut lengthwise along one end. The required lint-free cloth wipe test along the cuts left grey marks much like in your photograph. The immediate blame had been placed on "residue" from cleaning solutions known to not leave residue, but upon assessment under magnification I realized that the laser cut edge was simply a mess and the wipe test was pulling off little bits of metal like sandpaper on a rough cut piece of wood.

Running the parts in ultrasonics for a extended period of time seemed to help immensely.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

January 26, 2012

this text gets replaced with bannerText

Q, A, or Comment on THIS thread -or- Start a NEW Thread