Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Discoloration of black zinc plated parts

Q. Hi All,

reaching you for some help.

I'm restoring a couple of motorbikes and I decided to re-zinc the nuts, bolts and brackets. Originally the hardware was blue, yellow and black passivated. I took the parts to a industrial zinc place to get them barrel zinc'd. I wanted to avoid the marks left by the electroplating wiring process.

Now blue and yellow passivation is very good but black didn't come out well. The parts are dark grey and not uniformly passivated. Also, they put some cutting oil on the black parts to maintain the black. Can you black passivate barrel zinc plated parts? Is there any issue with this process?

Do I need to do the black parts with the electroplating wiring process for a better result?

Thanks everyone for your advise.

- Melbourne Victoria Australia

May 26, 2022

A. Hi Simon. Yes, black chromating can be successfully done in a barrel plating operation.

But your question involves expectations rather than being solely a technical question. The issue is that zinc plating is usually considered a functional finish rather than a decorative one ...

To offer an example of what I mean before discussing your problematical black parts: some shops do alkaline zinc plating and some do bright acid zinc. If you had had half of the the blue parts supplied by a shop doing alkaline zinc and the other half by a shop doing acid zinc they would not come close to matching in brightness, yet you'd have no basis for complaint as long as each batch was functional.

So, if the case were that the general color and shine of the black parts doesn't match your hopes & expectations, that would probably be solely on you. But if the parts actually look lousy and inconsistent you probably have grounds for complaint; I would suggest a call to the shop owner or manager telling him why you are unhappy and seeing what if anything can be resolved. But the fact that they oiled them means they already knew what they looked like; some engine parts might look perfect dark gray and oiled :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

May 2022

May 27, 2022

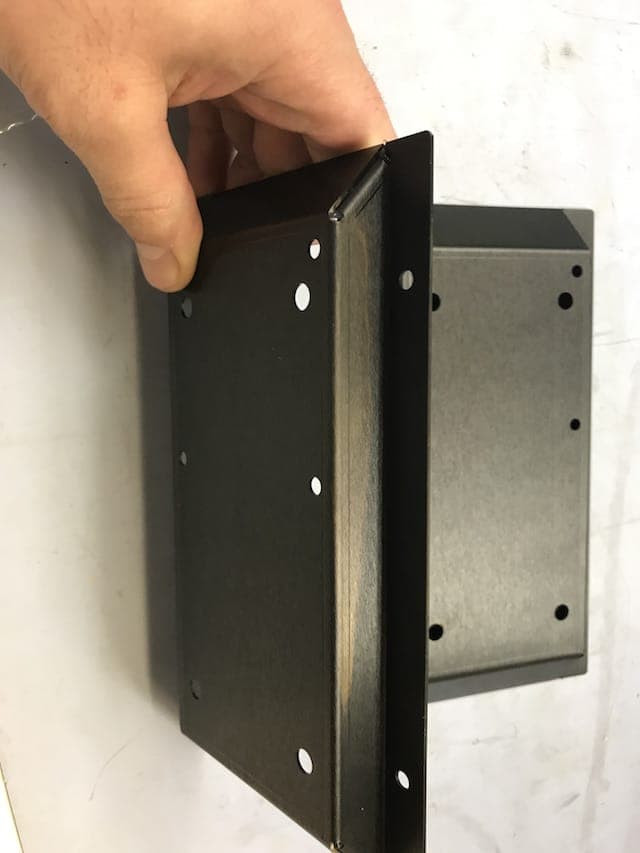

Q. Today I washed the parts and took some photos in sun light to show the result.

Anyone have a picture of black passivation of barrel zinc'd parts?

Simon biagio [returning]

- Melbourne Victoria Australia

⇩ Related postings, oldest first ⇩

Q. Recently I am receiving parts which are Black Zinc plated from my supplier which had discolored. Some quantity of them had "Brownish black" and "Greenish Black" appearance instead of the "Black color" that we usually see. My supplier is claiming that this is a process limitation in Black Zinc plating as that chromate contains 'Silver Nitrate' which is light sensitive and will discolor when exposed to UV.

Question:1) Is this normal in Black Zinc plating process?

2) What is the factor contributing to this change of color? Is it true as that silver nitrate will caused discoloration of black zinc parts?

3) Is there any form of certificate like MSDS that actually spelt out this limitation and potential discoloration?

4) Or is it actually my supplier poor process control? And what parameters should I get them to monitor?

Please advise

Engineer - Singapore

2007

2007

A. I would suggest that you speak to your designers and your plating shop about the possibility of switching to zinc-iron alloy plating. This alloy not only offers better corrosion resistance than zinc plating but, presumably because of the iron content, it can be more reliably black chromated without light-sensitive silver-bearing chemicals. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Silver nitrate IS what makes the chromate black.

UV might damage the black zinc finish but often the discoloration is due to a poor chemistry (--too much silver: dull, powdery finish; --too little silver: copper to brown color, poor coverage or blotchy; --not enough zinc plating: odd colors; --wrong pH).

The greenish-rainbowy flash over a nice black is OK, it is the chromate showing.

- Vancouver, BC, Canada

July 9, 2012

January 9, 2018

Q. We have several CRS fabricated parts which we have finished to ASTM B633 SC2 Type II black zinc chromate, and for years all of our parts (no matter what vendor we used) looked and functioned perfectly (mostly local fabricators and finishing shops). Now we are receiving parts with major discoloration and we can not accept them but I have no idea why this is happening and would very much like to aid my vendors in discovering what the cause is.

Design Engineer - Lawrence Massachusetts

A. Hi Justin!

Did you measure thickness where you have this shading? It seems to be very low or none.

Maybe it's the photo, but I would check it.

Keep posting!

TEL - N FERRARIS - Cañuelas, Buenos Aires, Argentina

February 5, 2018

A. Hi. I work in a small plating company. It seems to me that the problem could be a poor rinsing after passivation. If they are not rinsed well some solution could remain causing a drip on the piece that will cause discoloration. The overall finish looks good. If it was a chemical problem there would be more discoloration overall on the piece.

John Robert Brodie PerilliN.T.G s.c.a.r.l. - Casalazzara, Aprilia, Lazio, Italy

October 5, 2018

Q. Hi, some of my flat parts are having the same lighter patch like the very first few pictures in this thread [these pictures from thread 33784, "Blisters in Nickel Plating with temperature"]:

... but they were black-zinc-ed. Are those patches normal? They don't look good and we are wondering if we could remove them by re-doing the black zinc process differently?

Hank Ling- livonia, michigan, usa

February 17, 2020

A. Hi Hank. We didn't want to post your question about "light patches in black zinc plating" on our thread about "Blisters in Nickel Plating of die castings when heated" because no one will be able to find anything if we let the threads wander all over -- so we added your question to this black zinc thread, and copied the pics you mentioned here.

Light patches are not normal; and in general, defective parts can be stripped and replated ... but is the substrate zinc die castings or some other material like cold finished steel? Please send pics of your own parts to mooney@finishing.com for posting here because although a picture is worth a thousand words, 'like the other picture except ...' brings us back to the need for a thousand words again :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

February 2020

Q, A, or Comment on THIS thread -or- Start a NEW Thread