Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Sublimation Coating Formula

Q. DEAR SIR,

WE ARE A COATING COMPANY MAKING INKJET PHOTO PAPER AND HAVE TWO COATING LINES AND WOULD LIKE TO DO COATING ON PAPER WHICH IS USED FOR PRINTING AND THEN SUBSEQUENTLY HEAT TRANSFER ON TEXTILE AND MUGS.

CAN ANYONE GUIDE ME TO THE FORMULATION, NAME OF THE CHEMICAL TO BE USED FOR PAPER COATINGS?

WARM REGARDS

P.K. SARIN

- Delhi, India

October 25, 2014

Q. Dear Sir,

My Name is Brijesh from India. I want:

1. How to create a coating mug?

2. What coating Material are used in around the cup?

3. What Material are used in this coating? Please tell how to create this material. Material name & their mixing percentage.

- Bahadurgarh, Haryana, India

November 7, 2014

Q. Dear sir,

I have simple cups but I want to make them sublimatable to transfer the images. How do I do it?

Thanks.

- dera ismail khan, Pakistan

December 22, 2014

A. Hi Brijesh; Hi Babar.

I don't want to discourage anyone from trying to answer you, but 20 postings preceded yours on this thread, and this is but one out of more than 40 threads about sublimation coatings on this site alone. So the subject is broad. If the question is restricted to what coating to put on the mugs so they will absorb sublimated gasses, then polyester coatings, whether one part baked, or two-component reaction coatings, can apparently be used -- but remember that you need a food-safe coating. Many companies offer polyester coatings specifically for sublimation. If you are a coatings formulator, that should be a start. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

December 2014

Q. I am interested in printing heat transfers on 100% cotton fabric, please help me know the cheapest and colour fast way to do that. Thanks a lot. Bye

vinay kumarVINAY - Ghaziabad, India

February 5, 2015

Q. I am just getting started in the dye sublimation business, as a home business to supplement my income. You stated that spending the money on quality coating was most important, which makes total sense. Did I understand correctly that one can use dye sub inks, other than sawgrass successfully? I was warned against other inks, but if they can be used and result in quality products I would like to know. That would drastically reduce the startup costs. Thank you!

Eunice Alexander- Powel, Tennessee, USA

March 16, 2015

A. I use clear coat for cars with activator. I use 2 thin coats sprayed on, then cure in oven for 12 min at 385 °F. Works great on metal.

Kenny Moore- salem Indiana USA

April 19, 2015

A. I purchased an Epson XP-310 printer from Walmart for $59.00. I purchased empty refillable cartridges from Amazon.com along with the sublimation ink. Although the printer would say not genuine ink when I added the sublimation ink, it still printed really good. I purchased 400 sheets of sublimation paper from Dyepress. I use a oven at 400 °F for 15 minutes.

Kathleen McphersonK&A Customize Printing - Ridgeland, Mississippi USA

April 24, 2015

Q. I have a sublimation printer, inks & paper and heat press. Can I sublimate things that are not sold as sublimatable? For example- a piece of wood. Do I need to coat it with a clear coat or such before I can transfer onto it? What is recommended temp and time for wood? Thank y'all for any help!

Carrie Buse- Tupelo, Mississippi, USA

September 4, 2015

A. It usually all boils down to being all about the research and reasoning things out doesn't it? I also am just now getting started with sublimating tiles and other ceramics. The suggestion of using clear coat made sense to me, so I decided to do it the easy way and do the research myself.

There are basically three kinds of automotive clear coat. There's the (ACRYLIC) spray can that you buy at Walmart, (which I wouldn't hold out much hope for), a URETHANE based clear coat that mixes in two parts, a resin and a hardener (three if you count the reducer), and a POLYESTER (not polyurethane) based clear coat, which also uses reducer and hardener. Of the three, the urethane MAY sublimate, or it my not. I just don't know.

The polyester though is by definition what you need to sublimate. It makes a very tough polyester coating used for automotive and marine applications where wear & tear are the norm. Of course it's not what you need for apparel, but it should be good for any hard substrate like ceramics, porcelain, metal, hardboard, wood, stone, etc. It cures by a chemical reaction, not heat, so no oven time is required. There's also a product called "DOLPHIN GLAZE Self-Leveling Polyester Finishing", that you can get from Amazon that looks interesting.

I believe that the gel coat used for fiberglass is also a polyester compound that would have to be painted on with a brush or applicator of some kind.

Again, I'm no expert. I'm just now getting geared up to try some of this. I'm just passing on what I've learned from my research. I also got some Dyepress to try. The thing that bothers me about Dyepress though is that it's water based, and being a woodworker first I know that polyester resins and water don't get along very well. I've also heard reports about the release paper sticking to dyepress coated objects. I'll try it and we'll see.

Professional people will use professional products, and my money is on the polyester clear coat as the one that the professional don't want you to know about. I'll let you know what I find out as I try it, or if someone else tries, pass on the information.

Peter DeBrucque

- Greer South Carolina USA

September 12, 2015

October 1, 2015

![]() Peter,

Peter,

I found your post most helpful! Thank you for sharing. How did your trials turn out?

We are looking into sublimation on wood.

Thank you!

Signs - Texas USA

A. Hi Carrie. I have never done sublimation and can only respond from my book knowledge, but maybe even that is better than an unanswered question :-)

The idea behind sublimation is that the ink on your paper sublimates (turns to gas rather than liquid) when you heat it. If the paper is pressed against a substrate that can absorb it, it will. Thus, I think that the required temperature & time are defined by the sublimation ink manufacturer rather than the substrate.

I don't think natural materials like wood or cotton are good at absorbing the gaseous ink. I think you need a clear coat as described by others, including Peter, just above. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

October 2015

A. I am trying out some today. I know this thread is old but no one really answered it. It was a bunch of jumping around.

I been using a company out of Arizona since we started a year ago. The coating supply we bought lasted us a year (about 80 dollars worth). We are currently doing glass and blanks are now more affordable than ever before. We do t-shirts metal tags and even have our own type of dog tags made for paracord and are the only company in the paracord company offering our ideas to clients. No one wants to invest in sublimation when shoe lace charms are so ready available. Well shoelace charms cost about a dollar and your print time and glue (that's expensive glue to hold). We can press one out for about 60 cents that tag and all its more durable than shoelace which if you don't glue correctly it pops off and ruins the project.

Anyway, today I'm trying a new coating. As I learned it's all part of the poly family so I got polyurethane clear coat yesterday. Will spray. let it dry, and then plan on a small heat time cause it's glass. So I'm thinking 1:30 seconds at 300 because it will already be dry just need to bake the coating on or bond it together. Then I will use my transfer at 300 for 1:30 as well. Well image comes out great on my first glass. I tried now I'm just trying to see if it can be sustainable (smooth finish with no streaks and I'm not having to use a ⇦ this on eBay or Amazon [affil links] or load a hopper to paint it). Rather just spray on out of a can instead of mixing putting on and have runs in the clear coat or streaking.

Aaron keen- Seminary Mississippi USA

January 25, 2016

Q. Hi everyone I have been going through the thread; I was trying to do printing on EVA foam (from which Flip-Flops/Thongs/slippers are made). After searching a lot I found that it can be done with sublimation printing.

But I have some confusion will the listed primer/sublimation coating work good on flexible material like EVA? I heard some people use Loctite from Henkel but don't know if that can work. Your experience and some shadow on this might help me, thanks.

- Melbourne,Australia

January 27, 2016

Q. Hi,

1. When applying clearcoat should we also apply the hardener for it?

2. If so: How long should we leave the tile to cure? Or is there an alternative (quicker) method to cure?

3. If not: How long should we leave the tile to cure? Or is there an alternative (quicker) method to cure?

4. In 3D vacuum machine, when placing the print on the tile for sublimation - what temperature and time setting should we assign?

Please advise.

- Colombo, Sri Lanka

March 31, 2016

A. Hi Prem. I think you may be misunderstanding the meaning of the word "hardener" in this context. There are two general types of clearcoats:

- "single component" clearcoats, where water or solvent evaporates in the air or in an oven, or UV radiation cures the coating, leaving a solid coating behind.

- "two pack" or "2k" or "two component" clearcoats where nothing evaporates; instead, the two components chemically react with each other to produce a solid hard coating. Sometimes the two components are called "part A" and "part B"; but sometimes (and it's confusing) people will call "part A" the clearcoat and "part B" the hardener … but they're really just A and B, and there is only sticky syrup, no clearcoat, until the two parts mix and react. Once they are mixed they harden fast, somewhere between 10 minutes and 2 hours depending on the components and the mixing ratio.

That should answer questions 1, 2, and 3. Sorry I don't know the answer to number 4 but suspect it depends upon the sublimation ink, the press design, the pressure, the coating you are sublimating onto, etc.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

March 2016

April 7, 2016

Q. Thank you for your feedback, I did run an experiment by applying a 2-part clear coat on the ceramic (gloss) tile, allowed it to cure for 24 hours and then I sublimated a print on it at the temperature of 200 degrees for 6 minutes, the image came out pretty well but there were some problems that came along with it. They were:

1. glossy finish was compensated, it looked as if it's semi-matte.

2. there was a paper trail on top of the print sublimated, which I fear is what makes the print look matt (but I can live with that).

3. I also tried some testing on the sublimated ceramic tile:

a) I tried pouring water on the ceramic tile and the tile tolerated the water spill, so it's a pass.

b) I also tried spilling some thinner on the printed tile, but the print did not hold well, it slightly stained out, so it's a FAIL!

c) While doing this I noticed the clear-coat peeling off the ceramic tile like a transparent sticker, EPIC FAIL!!

Now my main concern out of this list above is the peeling off and the inability to withstand thinner; I believe clear-coat can hold thinner without an issue, but this gave me an opposite result. What do you think I did wrong? Peeling off is my main concern since we spend a lot on the clear coat, et.c just to see the image peel off is disappointing. The question that came up was: is the glossy ceramic tile's surface too smooth to hold on to clear coat? Have I missed something here? I would really appreciate your thoughts on this.

Thank you.

- Colombo, Sri Lanka

A. Hi Prem. I'm just the website administrator with some general knowledge of metal finishing. I've never even attempted sublimation coatings. Hopefully another reader will offer help.

But "thinner" is a very broad term. The first google link I followed offered Thinner 5, Thinner 222, Thinner 290, Thinner 308, Thinner 316, Thinner 357, Thinner 616, Thinner 902, Thinner 909, Thinner 990, and Thinner 995 -- all based on different solvents, as their basics. So what do you mean by "thinner"?

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

April 2016

Q. Hi I was wondering if anyone has any more answers on how to use the sublimation coating spray? Does it harden the cotton quite a bit? I'm interested in doing full t-shirt prints and don't want the cotton to look synthetic.

ruth viljoenhag moon - south africa

April 13, 2016

April 22, 2016

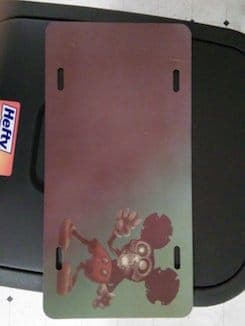

![]() I read about the automotive clear coats, tested a few, didn't have good results and then I read the suggestion about polyurethane. I bought a can of Minwax fast drying polyurethane clear gloss. Three coats on a sublimation license plate, using a 3D vacuum sublimation heat press with the temperature set at 185 and the time at 2 minutes 30 seconds.

I read about the automotive clear coats, tested a few, didn't have good results and then I read the suggestion about polyurethane. I bought a can of Minwax fast drying polyurethane clear gloss. Three coats on a sublimation license plate, using a 3D vacuum sublimation heat press with the temperature set at 185 and the time at 2 minutes 30 seconds.

Guess what ... it worked fantastically! Now I did have to put a automotive clear coat over it to make it bright and shiny like you would get from a sublimation plate.

Jeff johnson

The Print Shop - Lake Charles

Q. Dear Sir:

hope not to disturb you, I'm trying to remove the ink after sublimation and I have tried many solvents such as benzene

⇦ this on

Amazon affil link]

and acetone

⇦ this on

eBay

or

Amazon

[affil links] Warning! highly Flammable!

and others, but they didn't work. I hope if there is some solvent that is able to remove the ink without removing sublimation coat.

Thank in advance.

- Ismailia, Egypt

May 31, 2016

A. Dear Alkaraly,

Before, thinner used with success for the removal of ink. After, I switched to ethanol 98% successfully also. Put the pieces in a closed container with alcohol and wait some 24 hours and then scrub with a sponge. The ethanol is low cost in Brazil; it's a renewable product, and less toxic.

- Juazeiro do Norte, Ceará, Brasil

August 23, 2016

July 24, 2016

![]() Hi all,

Hi all,

Thanks Ted Mooney and others, I try it using polyurethane varnish. Result is OK. I apply it to wood from using paint brush. Dry 2 days and heat press 180 seconds in 320 °C heat.

Thanks again all.

- Nawalapitiya, Sri Lanka

August 18, 2016

![]() Hi, I am Ruth and live in England and am new to this forum. I have tried on and off for a number of years to make my own sublimation blanks and have had very little success.

Hi, I am Ruth and live in England and am new to this forum. I have tried on and off for a number of years to make my own sublimation blanks and have had very little success.

I have tried Digicoat opaque and white coatings with a little success, white did not work as when heated blisters popped up all over the surface, the opaque had better results but nothing spectacular. I was very interested to read about the min wax but could not get hold of it here. I bought a can of Valspar quick drying clear gloss and hoped for the best! Tried 3 coats and all I ended up with the sublimation paper stuck to the blank (sandstone with a finely ground level surface) and no ink transfer. Tried again with the 3 coats then cleaned the stone with Digicoat adhesive promoter (blank was a bit sticky afterwards but don't worry) then used the Digicoat opaque coating as per instructions on the can and used my 3D vacuum heat press for 2 X 8 minutes and the result was very good. Some colours work better than others, did not have much luck with blues and purples, this may have something to do with the fact that the stones came out of my oven quite golden after heating with the Digicoat even though they went in clear!

Thank you so much to the person who mentioned the minwax, I would never have thought about it had I not read about it here.

Cheers.

- Darlington, County Durham, England

Q. Hi sir,

I am sharath; I have take up sublimation printing recently. But when we take out the print, the colors are not exposing correctly in the output. Can you say how to set the color for the picture in photoshop?

- karimnagar, telangana, India

September 1, 2016

A. Sharath,

The color gamut for sublimation ink does not match the printer cmyk gamut.

- San Francisco, California, USA

July 10, 2017

Q, A, or Comment on THIS thread -or- Start a NEW Thread