Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

Thread 460/75

Finishing a stainless steel countertop

2007

Good Afternoon!

I'm so pleased to have found this site, and eager to see if I get a response. I particularly like your editorial standards page, and the author's style...

My Husband and I are attempting a very basic kitchen remodel... the one that will have to do until the one we really want to do can happen! ($$$$)

This "remodel" includes lots of painting, removing the upper cabinet doors (have to keep those shelves tidy and uncluttered, but adds a lot of openness) and new countertops.

Here is where we get to my many parted question...

I did some investigation and I am under the impression that you can glue 16 gauge stainless steel to a wooden substrate....using possibly a heavy duty contact cement? I thought we might try to lay a top piece just like you would plastic laminate..

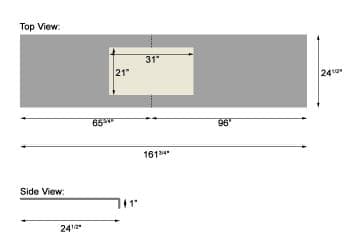

The local fabricator (we've asked to bid the cost of a sheet of SS cut to size, with a sink hole cutout and one bend along the front to serve as an edge band) indicated that (to save money) we would need to finish the surface ourselves, using a rotary sander, perhaps, with a "red pad". I understand he didn't want to give out his trade secrets to a DIY'er.

Could you elaborate on a home-made finish that would suffice for a countertop surface? One that was random and not too patterned would be my preference. I don't expect to match my brushed SS appliances, (long grain hairline?) and wouldn't want to, due to the noticeability of watermarks and such.

I assume the stainless at the local fabricator's is bright and shiny, which also wouldn't do.

Also, what would be the best filler for the seam? Silicone? The seam will be short, and mostly hidden under the sink.

The issue of the backsplash is a non issue for me, because I would tile something up the wall, to be artistic. However, blending the wall backsplash of tiles into the stainless top is still a question, wondering how to make the transition visually more clean.

Thank You so much for taking the time to read this, and thank you for being there to ask.

DIY'er, Homeowner,amateur artist - Columbia, South Carolina

publicly reply to Kerry Ann Crossley

2007

Thanks for the kind words, Kerry; yes, our "standards" do ask people to try to make their postings interesting by making them real, and you certainly caught right on, thanks! Although our specialty is metal finishing, we hope our readers can help.

I would expect contact cement to work well, and suggest that if you have never used it before, that you play with a couple of scraps to get a feel for it because you will kink your stainless sheet if you try to make adjustments. BarrysRestoreItAll [a finishing.com supporting advertiser] specializes in stainless steel repair kits and patinas; if you don't get good enough public answers, they can hopefully advise you on mechanical finishing and patina.

Silicone is an excellent sealant, although a lapped joint would be better if your fabricator can do it -- overlap the two sheets, folding the top sheet under itself for no sharp edge, and rout the wood in the joint area about 1/8 inches deep by 1/4 inch wide to allow for the extra two thicknesses of stainless.

I would probably use bull nose tiles for the bottom course and use silicone to fill that gap.

Then again, I'm a metal finisher, not Bob Villa :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

publicly reply to Ted Mooney

Q, A, or Comment on THIS thread -or- Start a NEW Thread