Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Was this shaft Double plated?

First of all,thanks again for this great site. one of the few that offers this much help to so many.

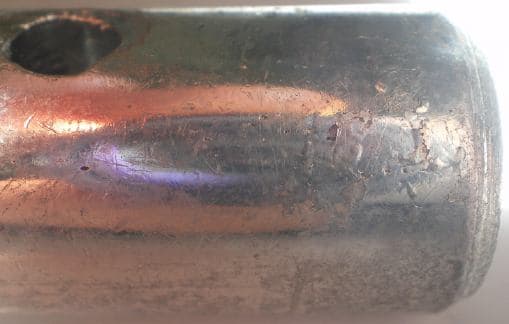

These shafts that we got have a defect, as you can see in the pictures --

Could it be that the producer tried to put a second coat over the first one?

The shaft's diameter is ~16 mm , and the coating thickness should be between 15 and 20 micron.

Sorry about the red glare in 1 of the pics but that's my fingers holding a small magnifying glass in front of the lens.

Jouke Brouwerbuyer - Israel

2007

Although pictures can be deceiving, it does look like two layers of nickel. Are they supposed to be nickel plated?

There is nothing necessarily wrong with two layers if it meets tolerance. It's done with rejected truck bumpers all the time. But special care must be taken to get good adhesion. Quite obviously that special care wasn't taken :-)

I'm sure you know it, but for the benefit of newcomers, this plating is atrocious and completely unsatisfactory.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

The shaft(s) is supposed to be galvanized.my first guess was that these (pic)are nickel coated.

but because I don't see a copper coat as base I believe the first layer is galvanized with a ,and I am sorry if this will sound silly,nickel top coat.

valve manufacturer - Dorot, Israel

2007

2007

Jouke,

Looks like,

1.Improper pre-treatment/cleaning.

2.If it is nickel check the bath for high pH

3.Also check and maintain Boric conc.

Regards

T.K. Mohan

plating process supplier - Mumbai, India

2007

Jouke,

Firstly this plating is pretty rubbish! However, before condemning it totally out of hand it is worthwhile understanding what you are having done. You do not mention what the shaft is made from, so that would be of interest. Secondly, you say it is galvanised; I understand this to be a zinc coating process, but accept that in other languages it is a generic term for electroplating - can you please verify whether there is any zinc on there, please?

The normal route for electrodepositing nickel depends on the substrate material, so this is important to know. However, it is not unusual in metal finishing to use "duplex" nickel, which is two layers with different structures and this helps in corrosion protection. The important thing about plating nickel on top of another nickel layer is to enure the first layer is properly activated. If the first layer is from a bath that contains organic additives such as brighteners and levelers, it is even more difficult. Your second picture clearly suggests the top layer is a bright nickel, so if the first layer is also bright, adhesion will be a big problem.

I also wonder about the stress of the deposit - it looks to me as if the top layer is quite highly stressed and coupled with poor adhesion, it is pulling itself off the substrate.

Can you give more details of who did the job (was it your company or a sub contractor?), what is the process being used and what are the bath compositions. Once we get this information we can start to help you and not guess and speculate about what we think we may being seeing here.

If the job has ben done by a sub contractor, I would suggest you take the work back to him and tell him to do it properly at his own cost. (This will not be cheap as he will have to strip off all the plated nickel and start all over again!). If the job is in-house, then we can suggest how your process can be improved.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

Q, A, or Comment on THIS thread -or- Start a NEW Thread