Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

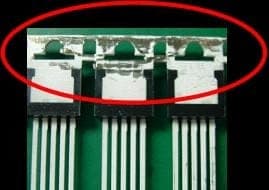

Peel off issue on TO263 nickel leadframes

We are now having problem on this package, peel-off is always present despite of all pretreatment chemical are in good working condition no changes in process from die attach up to plating. we need first to microetch the leadframe prior processing to solder plating to eliminate this defect. whats the best way to determine the root cause of this defect. why do its needed to etch first the leadframe, when previously its not included in the process.

please help.

Kathy Chuaplating technician - Philippines

2007

Microetch retains the original smoothness of the metal. Using a high power objective microscope, you will see that there are too many rough edges and spikes on the surface. These roughness can cause poor plating deposit, such as peeling off. If microetching alone solved your problem, then you can start from there. There could be changes that were made on your bare metal, be it on its process or on its raw material. Ask your vendor.

Good luck.

- Philippines

2007

Nickel requires a good activation prior to plating. If you are encountering peel off problem, it is due to poor activation of Nickel. Nickel Phosphorous is even more difficult to activate. Check your leadframe supplier if the material is Ni or NiP. Consult some chemical suppliers on a good nickel activator.

Germie Maravilla- Laguna, Philippines

2007

Q, A, or Comment on THIS thread -or- Start a NEW Thread