Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

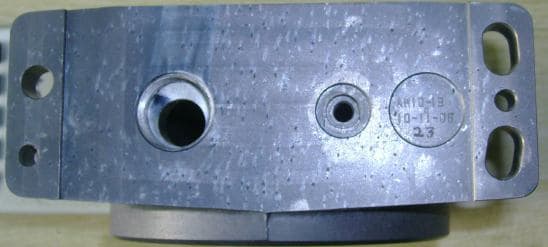

Dark spots on anodised castings

2007

Q. Hi,

We are experiencing darks spots when anodising and black dying some of our castings.

The material spec is BS1490 LM25TF, and we are using a sulfuric anodise process.

Are these spots caused by the porosity of the castings, or is there something else in our anodising process that would cause this?

Regards,

Production Engineer - Gloucester, UK

|

A. First, I hate castings. - Navarre, Florida 2007 A. Although Casting always behaves this way(for improper process), yours is too serious. - Singapore 2007 A. Castings and porosity can't be separated so you have to tailor your anodizing, both pretreatment and post treatment, to mitigate their deleterious impact. For instance, avoid etching the casting - don't open up more pores or expand those already present. Caustic etching is especially bad in this respect. If you must, keep time to bare minimum. Following anodizing, soak the parts in a weak, mildly alkaline solution such as sodium bicarbonate to pull out some of the sulfuric electrolyte from the pores. Good luck!  Milt Stevenson, Jr. Syracuse, New York 2007 A. John, Aerospace - Yeovil, Somerset, UK 2007 |

A. Hi, John

To answer your question, it is not the porosity (from original cast) but the porosity created in situ of the secondary phases that are inevitably dissolved (during anodising but could be mitigated) that gives the dark spotting.

To verify this (one way or another), sampling permitting, it could be easily done by scanning electron microscopy.

Senior Metallurgist - Leatherhead, Surrey, UK

2007

Q, A, or Comment on THIS thread -or- Start a NEW Thread