Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Etchant for recrystallized zone of FSW AA2219

2007

Dear All,

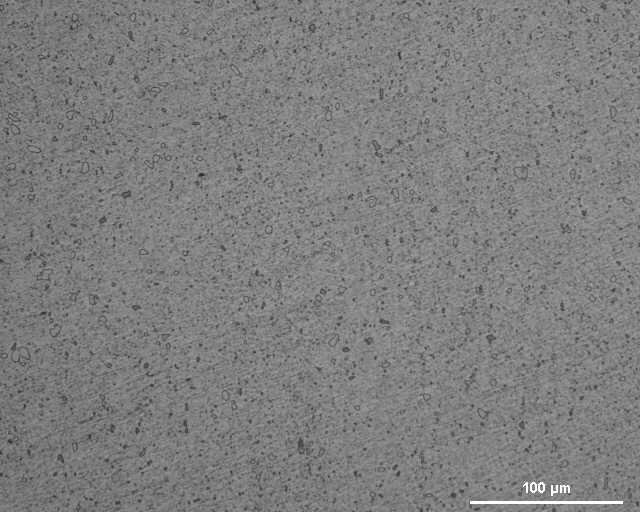

I am not able to see the Grain Boundaries the Nugget (Dynamically Recrystallized) region of Friction Stir Welded AA2219 (Al-6.3%Cu). The etchants simply do not highlight them, I can't see any demarcations except a dark region. Grain boundaries are etched to a relatively OK status (they are not as well defined to see clearly) in TMAZ, HAZ and BM. I have already tried the following reagents in step os 10 sec (starting from 20-30 seconds to 90 maximum after which its totally dark !)

The etchants which have been used are:

1. 1% NaoH

2. 10% NaOH

3. Keller Reagent

4. Kroll Reagent

5. Dix and Keller

6. 0.5 vol% HF

7. H20*HNO3+HF+HCl

8. H20*HNO3+H2SO4+CrO3

Dynamically Recrystallized Grain size is generally reported as too small in order of 5-20 micrometer.

Research Scholar IIT Delhi - present address: Institute of Material Research, TU Dresden, Germany

Hi Kanwar,

I am not very sure but you may try Barker's etchant and then examine under cross polarised light.

Barker's etching : The specimen to be anodised in an electrolyte e.g.

4 - 5 mls of HBF4 in 200 mls D.I.water; use lead strip as cathode at voltage 20 d.c. for 1 - 2 minutes. Always make sure that a gap between the micr-sample and the lead cathode is maintained around 1 inch. Hope you may get better result.

Good luck.

Basu

- Dubai, U.A.E

2007

Q, A, or Comment on THIS thread -or- Start a NEW Thread