-----

Corrosion and fuel blockage in Ford diesel fuel tanks

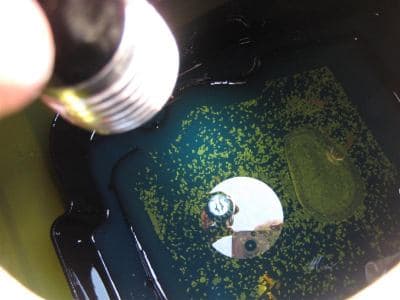

(Photos courtesy of Chris R. 9/13/11; see page 3 for more & larger)

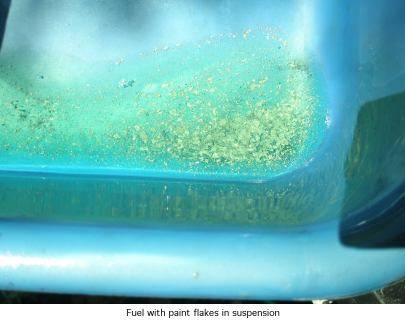

(Photos courtesy of Tim H. 9/13/12; see page 3 for more & larger)

Q. I have a 2016 Ford F-350 6.7l diesel super duty dump and had this same issue. And it cost me a small fortune to repair and I'm wondering if there is still a lawsuit going on as I'dlove to file and join because this came at a time where I literally ruined my small business growth and caused major hardships all while I was already going through enough as it was, so this was the icing on the cake. Much more that I don't want to get into. But I need to know if there is a lawsuit and how I can get involved please. My email is rmalyszko85@gmail.com if you can please contact me that'd be great. Thank you!

Rafal MalyszkoOut of business owner - New Britain, Connecticut

December 14, 2021

⇩ Related postings, oldest first ⇩

Q. The diesel fuel tanks in a fleet of trucks are corroding and showing rust on the inside and leaving some type of debris that appears to have come off the inside off the tanks. It is thin , leafy and grayish in color floating about in the bottom of the tank. Could this be galvanize or aluminize coating that has failed to adhere. The inside of the tank has a grayish color coating. The coating is coming off mostly on the bottom, but not exclusively, some of the coating is coming off the inside top and sides.

This is causing clogging problems throughout the fuel and injection system. Do you know what this coating is and what could be causing this problem. The tanks came on the trucks from the factory and have not been modified in any manner. This problem is on a somewhat large fleet of trucks and not just an isolated problem.

- St. Louis, Missouri, USA

2007

A. Frank,

It could be anything. Your thoughts are as good as anyone else's. The company needs to contact who they bought the trucks from and have a long conversation. I would assume that they are under warranty. Rework of a tank for either plate or paint is difficult, especially when contaminated by diesel fuel. I thought that the big rig trucks used stainless, as diesel fuel is really hard on most finishes.

- Navarre, Florida

2007

A. It isn't galvanize -- galvanize is never used for (insides of) diesel tanks.

Aluminum-coated steel is a common diesel fuel tank material, as aluminum is unaffected by diesel. The aluminum is metallurgically bonded to steel by hot dipping; it protects the steel & won't flake off. Determine whether the material is oily, plastic or metallic. Microbes can breakdown diesel -- has this been ruled out, as by biocide use?

Any (non-waxy) plastic would seem to be a tank lining. Do a web search for your vehicle(s) to determine possible fuel tank lining(s) and for possible recalls or service bulletins.

One possibility: a polymer coating that either didn't cure properly or was applied over a poorly prepared surface. I.e., a manufacturing defect. Depending on vehicle age, the manufacturer may fully or partially cover cost of replacing the tanks. Replacement tanks of aluminized steel with black powder coated exteriors are available for nearly all trucks. Install one and see if that solves the problem.

As the problem could cause a vehicle to stall in traffic, it may be considered a safety defect. If no satisfactory responses from dealer & mfr., consider parking a few disabled vehicles in dealership driveways and contacting your Congressman and the NHTSA.

- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

2007

A. Could it be something in the fuel that adheres to the tank walls to the point it is thick enough, then comes off? Maybe investing a little in a lab analysis will prove beneficial. What are the tanks made of? If they are stainless steel this wouldn't happen.

Guillermo MarrufoMonterrey, NL, Mexico

2007

|

A. Ask if the trucks have used any biodiesel. It is a great fuel and an even greater solvent. There may have been a coating on the inside surfaces of the tanks that the biodiesel has cut through. I doubt you'd see problems with B-5 (5% biodiesel in 95% diesel). B-50 or higher (50% biodiesel) has much greater solvent power than diesel. - El Dorado, Arkansas 2007 Q. The tanks are not stainless steel. They are made out of steel which is rusting on the inside. The debris lays in the bottom of the tanks and is grey leafy looking. Frank DeGuire- St. Louis, Missouri, USA 2007 |

A. What is described is the symptom, but you need to know what is the source of your trouble. Your description of a "leafy" material is odd indeed and seems to foretell of a delaminated coating of some type, but I am not convinced this is what you are seeing. Have you attempted filtering out this stuff "floating about" in the tank? I would recommend fully draining the tanks and completely filtering the fuel as a first step to get after this problem. Need a better idea of what exactly is in that tank and, in particular, just what this gray material might be.

You realize of course that one common source of trouble is excess/free water in the diesel fuel. Where do the drivers fill up the trucks? Do you have your own fuel farm or do they fill at convenient retail locations as needed? If the former, I would be checking the condition of these to make certain there is not water pooled at the bottom of those tanks. Fuel tanks also must not be open to air as the fuel will pull moisture from the atmosphere which can lead to a host of problems. Check the tank breather valves. If you buy fuel retail, then I can only suggest that you use only high-volume stations that have rather high and fairly constant turnover rate (i.e., stations that always stock "fresh" fuel -- truck stops are a prime example).

Commercial biodiesel is generally trans-esterfied veggie oil and that generally derived from soybeans. If you are making use of this excellent renewable resource and it is from a high-volume commercial source, be certain they certify the fuel meets the ASTM spec for diesel, ASTM D975. If the bioD is more home-brew variety, it is possible it was not washed properly and may have undesirable, left over glycerin and/or water in it (and large commercial sources are not immune to this problem either). Depending on the type of diesel engine in these vehicles, water/glycerin in the fuel will generally lead to failed injection pumps and/or stalled, fuel-starved engines with clogged fuel filters.

How has the fleet been handing the crappy fuel? Are you regularly checking the in-line fuel filters and whether the water separators are collecting significant amounts of water or other crud?

More info needed.

Regards,

Thomas Hanlon, Materials Engineer

aerospace finishing - East Hartford, Connecticut, USA

2007

A. I worked in the fuel systems industry for a few years designing diesel tanks for trucks and light commercial vehicles. I have come across a similar problem before, but it was related to the poor quality of the diesel being used, and not the tank corroding.

If you are running a large fleet of trucks and they are out of their warranty period, my suggestion would be to switch to Aluminium tanks or even better rotationally molded LPDE Tanks.

Good Luck

- London, England

2007

2007

A. Howdy,

We are having a similar problem with a small fuel transfer tank and have gone through many filters on the equipment. It appears that the

"mill scale" formed in making the steel is delaminating and corroding. It leaves "fines" in the bottom and a horrible rust. The tank had obviously be low on contents for a while; The bio diesel started cleaning the tank; and water started condensing inside. Viola, ze mess.

We figure the scale will eventually quit, but not the rust. Noteworthy is the fact that steel "sweats". Yes, it absorbs water and gives it off as condensation as a result of temperature change. Our bio-diesel likely is siphoning the moisture through the walls of the tank.

We will be decommissioning this tank.

Regards,

Chuck

- Sanford, North Carolina

This is exactly what is happening in my Ford E350 van. It is a known problem. The inner lining of the tank is coming off. It looks a lot like flakes of silver spray paint. My tank was about 1/2 flaked away before it started giving me lots of problems. Stalling, fuel starvation, rough running.

This is exactly what is happening in my Ford E350 van. It is a known problem. The inner lining of the tank is coming off. It looks a lot like flakes of silver spray paint. My tank was about 1/2 flaked away before it started giving me lots of problems. Stalling, fuel starvation, rough running.

It was covered in TSB 19728. Ford has redone the inside coating design of the tanks, but if like me, you are outside warranty, you are SOL. The only solution ford had was replace the tank for $600 + labor. Needless to say as the owner of a 80000 mile 3 year old vehicle I am not happy with Ford.

- North Augusta, South Carolina

2007

My 2005 F550 Diesel with 47000 miles is being repaired as we speak for delamination of the fuel tank.It is out of the 3/36 warranty.This is a defect,Do not stand for this,Ford should honor this and recall all vehicles with this problem and refund any monies paid to have this fixed.They have done things of this nature before, my 1993 f250 sent fuel into engine after the truck was shut off and filled it with fuel causing it to flood out and cost me over $800.00 about a year later I caught a news letter that said ford was reimbursing the money for that problem.I called ford and got the money.This problem with the tank is going to happen to everyone,I never used anything but diesel,no bio, no heating oil,no additives.If we all complain to national transportation and safety commission they will take it up with Ford,its the only way.Go on the web find the sight and fill out the form stating the problem.Ford is making money hand over fist on their defective product in repairs and some have blown motors and putting the same defective tank in again.We all work hard for our money, don't let ford take yours.

My 2005 F550 Diesel with 47000 miles is being repaired as we speak for delamination of the fuel tank.It is out of the 3/36 warranty.This is a defect,Do not stand for this,Ford should honor this and recall all vehicles with this problem and refund any monies paid to have this fixed.They have done things of this nature before, my 1993 f250 sent fuel into engine after the truck was shut off and filled it with fuel causing it to flood out and cost me over $800.00 about a year later I caught a news letter that said ford was reimbursing the money for that problem.I called ford and got the money.This problem with the tank is going to happen to everyone,I never used anything but diesel,no bio, no heating oil,no additives.If we all complain to national transportation and safety commission they will take it up with Ford,its the only way.Go on the web find the sight and fill out the form stating the problem.Ford is making money hand over fist on their defective product in repairs and some have blown motors and putting the same defective tank in again.We all work hard for our money, don't let ford take yours.

concrete - Philadelphia Pennsylvania

2007

Q. We are just going through the same exact problem with our 2004 Ford F-550..... Now that I see a lot of others having the same problem.. I will have to try to get in touch with Ford...

Cheryl J- Livingston, New Jersey

2007

2007

I have a fleet of trucks in the So. Cal area and none of the gas trucks are having this problem with the fuel tanks. But, the diesels (2 of them) are both having the same problem. It has caused fuel pump and injector failure. Repairs of over $3000 per truck. Now, I have the fuel tank out and I have the metal particles inside the tank. The same particles that were in the injectors and the pump.

I have a fleet of trucks in the So. Cal area and none of the gas trucks are having this problem with the fuel tanks. But, the diesels (2 of them) are both having the same problem. It has caused fuel pump and injector failure. Repairs of over $3000 per truck. Now, I have the fuel tank out and I have the metal particles inside the tank. The same particles that were in the injectors and the pump.

I have one tank at a radiator shop and we are going to strip the coating out of the tank. If this works, I will be doing the other tank. All this and Ford said that we are out, because it is caused by the fuel and not the tank. What liars.

I have 18 F-series trucks and because of the negligence on this matter, I am looking into the W series GMC's for my replacements. I am hoping that my Ford rep will step up, but they probably won't.

- Newhall, California

Q. I finally had the material that was floating around in the tank analyzed and a piece of the tank which I cut out of the tank itself. The grey leafy material and the loose material still hanging on to the piece of fuel tank turned out to be aluminum. My conclusion is the aluminized coating on the inside wall of the tanks has failed.

By the way this problem I have been researching happened on a fleet of trucks used by one of our local utility companies. Not exactly a small isolated incident.

- St. Louis, Missouri, USA

February 6, 2008

Q. OMG! I'm in the middle of a huge fleet fuel tank delaminating crisis with our diesel trucks. I represent a huge fleet for The Brickman Group and we are having much of the same challenges when it comes to our Ford diesel trucks. Ford is telling us that it's the fuel (Bio-Diesel) that is causing this problem and I'm not 100% convinced. I was also told that it may be additives inside the Diesel fuel that react with certain metals (Nickel) within the fuel tanks. I've been trying to get a straight answer from fuel distributors and manufacturers and also from Ford, but both continue to blame the other without actually COMING out and blaming the other. Someone please tell me who I need to contact or what I need to do to get this matter resolved A.S.A.P.

Emanuel Mijangos- Gaithersburg, Maryland

March 5, 2008

A. Hello,

I'm also heard that the new bio-diesel gives corrosion in the stainless steel tank. Protection with a passivation in the tank can eliminate this problems. I know Volvo do this to the new tanks they build

Regards,

Anders Sundman

4th Generation Surface Engineering

Consultant - Arvika,

Sweden

March 8, 2008

A. Waste vegetable oil will react with galvanized steel and cause a delamination. It will also react with copper. I'm not 100% sure about the biodiesel in that the free fatty acids should have been neutralized in the reaction to make the fuel.

Biodiesel is an excellent solvent and will clean out the entire fuel system. That is why users are encouraged to start with a small percentage, say 5% (called B5). Any accumulated sludge will be removed from the system and caught in the fuel filter. After a few tankfuls of biodiesel, the contamination should be removed and you can run up to 100% biodiesel (B100).

However, if you are seeing a reaction with the galvanized steel in the system, that will most likely not get better.

Contact the National Biodiesel Board regarding the reaction with galvanized steel. It may indicate some fuel that was not up to ASTM specifications. I'm not sure. I run heated waste vegetable oil and biodiesel but do not have any galvanized steel in my fuel system (Ford F-250). I've been running these fuels for 75,000 miles with no problems.

- El Dorado, Arkansas

March 10, 2008

Q. The problem is aluminum coming loose, not galvanize. It seems to be happening to the larger service type Ford vehicles such as boom trucks and heavy materiel haulers. 450 series and larger I think. I wonder what kind of fuel tanks the GM, Mercedes, Volvo, etc. of this particular size service truck used around that time period (2004). By now I am sure Ford is well aware of the problem, I wonder what they have done to eliminate it on the new trucks ?

As far as the bio-grade fuels go. Someone will have to do a comparison of trucks that have not used bio-grade versus those that have. Collecting and verifying that kind of data could be tough.

- St. Louis, Missouri, USA

March 19, 2008

|

S |

May 12, 2008 Q. Two old gasoline-burning Subaru station wagons (1983 and 1987) have experienced fuel system blockage from fuel tank corrosion. I believe the problems started about the mid-1990s but I'd have to look up my records to be sure. Both spent all, or nearly all of their lives in Anchorage, Alaska and the 1987 still runs fine with 102,000 miles. They started fine in any temperature, and ran well when standing still, but soon experienced bucking and kicking from fuel starvation after the fuel sloshed around a bit. The problem got worse over time and the 1983 went to auto heaven 2 years ago when my mechanic could not figure out the problem; as I recall, he said he changed the fuel filters but never checked the fuel tank. - Anchorage, Alaska May 29, 2008 A. I strongly suggest that anyone interested in this subject view the description of changes in sheet steel plating for fuel tanks described in a patent summary at: - Anchorage, Alaska May 28, 2008 This is a followup to my May 12, 2008 post on fuel tank inner plating failure in 83 and 87 Subaru DL wagon, resulting in fuel filter clogging and fuel starvation. After the 87 fuel tank contamination was cleaned out by thorough steam cleaning a month ago, the 87 has run fine. In a couple of days I'll take it in for change of fuel filters, and keep the old one for analysis (I forgot to tell the tank cleaners to keep samples) in case there is still some residue in the tank. - Anchorage, Alaska July 21, 2008 This is partly a restatement of my May 29 post so I will shorten it up: - Anchorage, Alaska May 29, 2008 A. I strongly suggest that anyone interested in this subject view the description of changes in sheet steel plating for fuel tanks described in a patent summary at: - Anchorage, Alaska |

Q. Similar diesel fuel tank deterioration has been reported to me by a local contractor with his fleet of Ford dump-trucks. Have any of you have had success getting a resolution from Ford or otherwise?

Mark Cermele, Esq.Attorney - White Plains, New York

May 22, 2008

(you are on the 1st page of the thread) Next page >

Q, A, or Comment on THIS thread -or- Start a NEW Thread