Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

WHITE RUST ON ELECTROLESS NICKEL PLATED PARTS

We are a Metal Fabricator located in California.

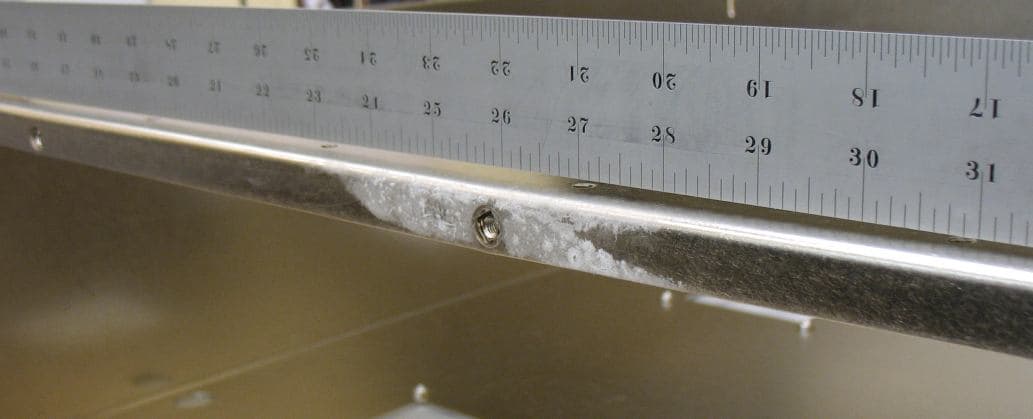

I am having problems finding out if Electroless Nickel plated parts can form white rust. I just received a call from a customer of mine that is located in Oregon and just showed me images of a part that we shipped in 3 weeks ago. The part appeared to develop rusting around a hardware hole. The length of the rust extended 5 inches and appears to be equal length on both sides.

My question: Is this white rust or carelessness on the part of my plater? Did the plater leave an acid residue on the part that was not noticeable? The parts were wiped down with Isopropal Alcohol prior to shipment.

Was there an insufficient rinse? Curing problem. Also please note that there were no subsequent operations to plating.

Logistics Manager - Fremont, California

2007

My guess: The white rust is the result of careless pretreatment prior to EN plating causing poor adhesion and defects in the EN. Once water or alcohol or any other polar fluid penetrates defects in the plating, the aluminum substrate preferentially corrodes along the interface, lifting off the plating. Ask your plater to pull the paperwork, in particular the shop traveler, and generate a Corrective Action Report for you.

To the left of the threaded hole, directly beneath the 25 on the ruler, is that the remnants of lettering, perhaps '20X'?

- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

2007

2007

Is the part developing this defect or was it there after unpacking?

If it was there after unpacking I would suggest leaking from one of the holes (not necessarily the one on the picture)In that case it could be EN bath dried up.

If it's developing you really would expect to see the nickel layer breaking up. (if there is a white Al corrosion product underneath) I myself have never seen EN corroding white.

- Netherlands

Q. There is white residue all over the brass EN plated parts and the plating is rough. Parts have a nice machined surface prior to plate. What is could it be?

manufacturer of coaxial connectors - Beverly Massachusetts

June 15, 2017

|

A. Come back and tell us whether the brass was "leaded" and also tell the prep cycle.  Robert H Probert Robert H Probert Technical Services Garner, North Carolina  June 21, 2017 A. Hi Pat, - Agawam, Massachusetts, USA June 20, 2017 |

Q, A, or Comment on THIS thread -or- Start a NEW Thread