-----

Consistency of Anodizing Thickness

Q. Hi.

For electroplating, the deposits are thicker at the edges and thinner at recesses. Can the same be said for an anodized deposits?

Thanks

New Crown - Hong Kong

2006

A. Hi Vincent. The general answer is no, anodized coatings do not tend to be thicker at the edges like electroplated coatings. This is why:

In both cases, the implications of Faraday's Law of Electrolysis apply, i.e., that the coating thickness in any area will be proportional to the current flow to that area. And in both cases the implications of Ohm's Law will apply, i.e., that the current will tend to take the path of least resistance. But the difference is that anodized coatings are highly insulative, which tends to drive the electricity away from the area where the coating is thickest and towards the area where the coating is thinnest, so the coating thickness will generally be fairly even.

But please tell us your situation rather than casting your question in the abstract, because a hundred ifs, ands, and buts can always apply and may bite you, but there is no way we can discuss every one of them. But if you tell us your actual situation, we might know if one applied, and be able to inform you or warn you about it. Thanks!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello,

We anodize plates (plate thickness 0.3 inches and more). Plate sizes 20 x 20 inches and more. Titanium screw as mounting points. Current flow area calculated with reserve.

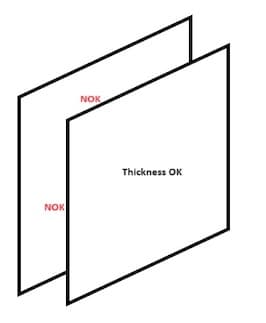

The distance between the two plates is 2-3 inches. We have observed significant differences in the thickness of the oxide coating of the "outer" sides (facing the cathodes) and the "inner" sides - shielding. We found significant decrease in thickness towards the center of the plate - of course on the inner surfaces).

We anodize aluminum series 5XXX and 6XXX. thickness required about 0.001"

Parameters and bath temperature - market standards.

What could be the problem that we have overlooked? Suggestions welcome.

Regards,

Tomasz

electroplating shop - Zdunska Wola / POLAND

August 20, 2024

A. Hi Tomasz

While it's true that coatings which become insulative like anodizing and electrophoretic coatings suffer far less from current distribution problems than conductive coatings like electroplating, asking for equal coverage on the center of a well-shielded 20" x 20" plate is apparently asking too much.

Putting eductors below the gap might help somewhat, but the problem may remain insurmountable. Hopefully a reader with specific experience in a parallel plate process will respond.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

|

|

A. Anodize has very good throwing power, but it is not infinite. If you are going to coat these plates as a parallel assembly, you will need to fit an auxiliary cathode between the two plates to minimize the variation. Chris Jurey, Past-President IHAALuke Engineering & Mfg. Co. Inc. Wadsworth, Ohio  A. The only way you can "fix" this problem is to have a cathode between the sheets. You can use a scrap sheet on the same load, but it CANNOT have connection to the anode-side. But it MUST have connection to the cathodes. You can do this by isolating it with plastics where you "hang" it from your bar and have a bridge from Cathode to Cathode, and at the same time connecting to your "new" cathode between your sheets. Other than doing this, you will suffer from low thickness between the sheets. There is no magic solution here. Production Technician - Horsens, Denmark

Inside a cell of about 1.5x1 inch the thickness drops 50% over a distance of 2 inches. electroplating shop - Zdunska Wola / POLAND |

A. Hi

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread