Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Rust on powder coating

Hi all,

I got one sheet metal product made of SECC(Zinc coated).. Which has been kept for around 10 months in well packed condition & in a good environment,got rusted in some areas..Difficult to find out the root cause..Can any one help me on this issue?

- Marsiling, Singapore

2006

This is a little confusing, can it be clarified? Are the parts powder coated over zinc? If that is the case the problem would be the plating not the paint, unless the coater sanded off the plating to prevent certain quality issues that the zinc can produce.

Sheldon Taylor

supply chain electronics

Wake Forest, North Carolina

2006

2006

Hi Taylor,

Thanks for your reply. This is not plated with ZINC.. It is an Electrolytic Galvanized Steel Sheet pre-coated. The Material Specification is JTS G3313 SECC. Attached is the picture of the part got rusty. Can you advise me what will be the root cause for this issue..

Thanks

Franklin

- Marsiling,Singapore

We did not receive any photo, Milton; please email it to mooney@finishing.com. JIS G3313 is the Japanese Industrial Standard for Electrolytically Zinc Coated steel. Whether one says zinc plated, or electrolytically zinc coated, or electrogalvanized, it is just a matter of wording. But SECC only means "Steel, Electrogalvanized, Cold rolled, Commercial quality" -- it doesn't describe thickness, post treatment, or any priming. It is indeed difficult from 12,000 miles away to determine the root cause of why something rusted :-)

But if we get the photo we will look at it.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2006

2006

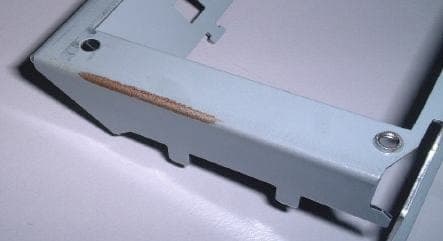

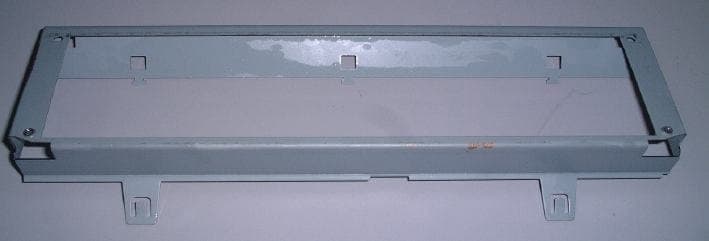

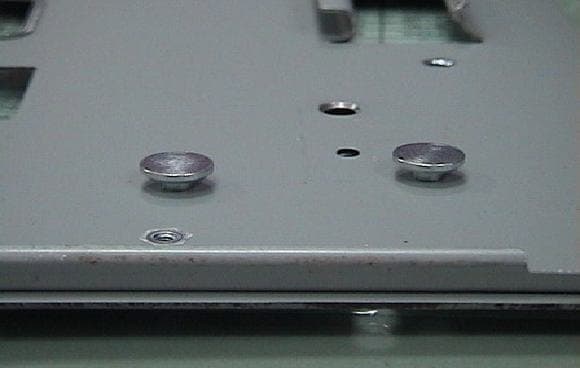

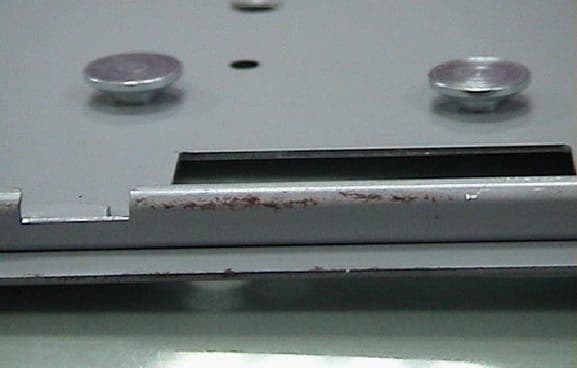

Attached is the picture of the part got rusty.

|

|

|

|

|

|

Can advise me what will be the root cause for this issue.

Thanks

Franklin

- Marsiling,Singapore

Again, this is just an impression from pictures viewed from the other side of the world, but it looks like there are at least 2 major issues. First, there is no paint/powder coverage in a broad area in the picture at upper right. This lack of coverage extends even to sheared edges in the picture at upper left. If the steel is protected by neither galvanizing (at a sheared edge), nor by paint/powder, it is going to rust quickly. The second problem seems to be rough handling that should not be occurring; looking at the picture at lower right, the bright spot at the right of the rusty rolled area is apparently an exposed burr raised from such rough handling.

My overall impression is that all of the rolled edges and extremities seem to be suffering from this rough handling that may have worn through both the powder and the galvanizing. But on top of that, it seems that your company is also not quite clear on what you have and what you want; and after 3 postings you still haven't explained your situation -- are you the customer, the manufacturer of the parts, a distributor, or what? Thanks.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2006

Q, A, or Comment on THIS thread -or- Start a NEW Thread