Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Bubbles in surface of clear powdercoat. Mild steel with no sand blasting.

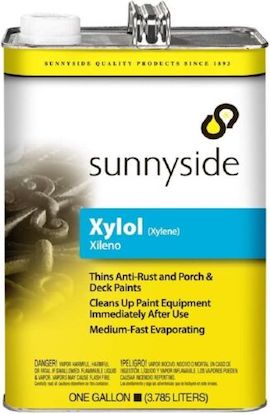

We are custom metal fabricators and powder coating is called out with increasing frequency. We have a client which represents the lion's share of our powder coating which is a national retail chain in high-end malls. We fabricate their store fronts and sometimes their doors. They like clear powdercoat so the raw steel is visible. For this reason, no blasting or grinding can be visible. The store fronts are different combinations of mild steel square and rectangular tube, flat bar and angle. Sometimes we get some bubbles as described above. I have been given a number of explanations. Outgassing due to residual mill scale seems to be a common theme. We clean all parts with Xylene ⇦ this on eBay or Amazon [affil links] prior to sending them out and individual coaters use a variety of preparation methods. Since blasting is not an option, are there in fact preparation methods which will mitigate or eliminate the bubbling? We aren't comfortable with a single source for anything we outsource but at the same time I need a fairly consistent result from several different powder coaters. If I know what methods will give a consistent result, I can include that process as a specification for the job. Bruce J. Garwood

- Cedar Hill, Texas

2006

You don't say what pretreatment the coater is doing before applying the powder.

If nothing (and really only your solvent wash) then find another coater.

You need a zinc phosphate or perhaps iron phosphate pretreatment system before powder.

Geoff Crowley

Crithwood Ltd.

Westfield, Scotland, UK

2006

Q, A, or Comment on THIS thread -or- Start a NEW Thread