Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

MIL-C-5541 Chemical Conversion Coat -- Legacy Q&A's

Q. I am revising a legacy drawing that has a note to chemical conversion coat (Alodine) per MIL-C-5541, grade B. I am unable to find a reference to grade B. Do I need to be concerned about this? Should I also include the class 1A or 3?

Thanks,

Jeff Seufzer

Manufacturing Engineer

ESSEX INDUSTRIES - ST. LOUIS, Missouri

2006

A. For proper coating selection and specifying, see

MIL-DTL-5541

[⇦ this spec on DLA] F. If doing the coating, use appropriate products from QPL-81706. Type II (non-hexavalent chromium) coatings can now be specified (although a QPL update seems significantly delayed).

In MIL-C-5541A (1964), Grade B indicates brush-on application, now Method B. Is this appropriate for the part (specifying a Method will disallow other Methods)?

QPL-5541-25 (1968, 1969 & 1970) shows that Grade B products were available for Classes 1, 2 and 3, so no clue there. Also, Alodine® is a brand name, not a specification, with many versions (the original Alodine introduced in 1945 produced a greenish phosphate-chromate coating).

For the original MIL-C-5541 (1950), I have very limited info. Most early products were phosphate-type. Requirements were 168 hours salt spray resistance (500 hours painted), and products were qualified per application method (spray, brush and immersion) -- perhaps the 'Grade.' Apparently, no separate Classes or Types. From US Navy lab testing reported by Sara J. Ketcham in The Finishing of Aluminum, G. H. Kissin, editor, (1963), the MIL-C-5541A revision added Class 3 for low electrical resistance, and (I surmise) the thickest coatings were designated Class 1 (for max. corrosion resistance when unpainted) and an intermediate thickness Class 2 was created for better paint adhesion.

Classes 1 and 2 were superseded by Class 1A in 1970 -- see Paragraph 6.3.1 of MIL-C-81706.

The MIL-C-5541A classes correspond roughly to Classes 1, 2 and 3 still present in

ASTM B449.

MIL-C-81706 and QPL-5541-25 are still available from ASSIST, as are current 5541 & 81706 specs.

- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

Q. In MIL-DTL-5541, what is "Method C". I am unable to find anything that will explain what that is.

One of our processors states that it may be an old antiquated form that was ditched long ago. But I find no reference to it in the 1990 specification.

- Monroe, Washington

August 9, 2024

A. Hi Pamela,

It's not quite clear to me that it was ditched :-)

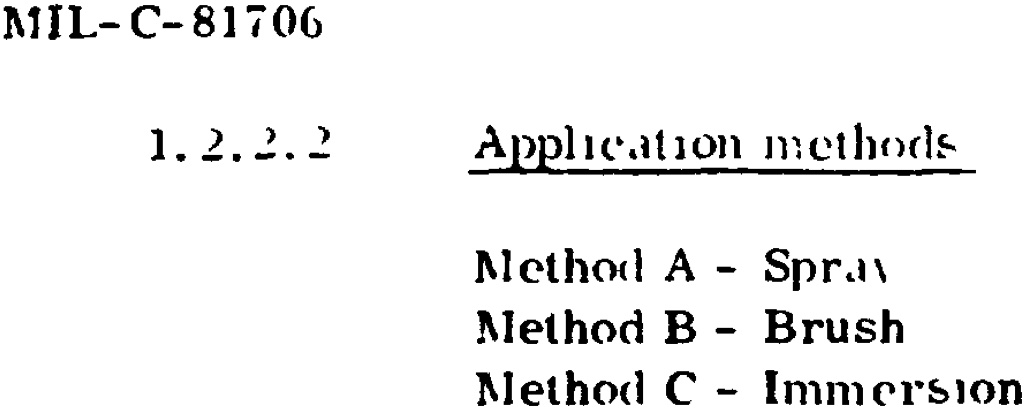

MIL-DTL-5541 requires the use of approved coating materials, as listed in QPL-81706. Although QPL-81706 has been superceded by a database, it made clear that Method A is spray, Method B in brush, Method C is immersion ⇨

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. The QPL-5541-25 ⇦this spec on DLA lists Type I & II, my understanding is MIL-DTL-5541 [⇦ this spec on DLA] introduced non-hex chromium. So then what are the two types in the Mil-C-5541?

Enrique BejarQuality Engineer - Santa Ana, CA

August 23, 2024

A. Hi Enrique,

While we may think of the words "type" and "class" as synonyms, it's common for specifications to use those two words separately, such that you may have a Class 1a (maximum corrosion resistance) vs. Class 3 (low electrical resistance) coating, while also having a Type 1 (hexavalent chromium) vs. Type 2 (no hexavalent chromium) coating.

To be a stickler then, there never were two Types in Mil-C-5541, there were two Classes :-)

You can download MIL-DTL-5541

[⇦ this spec on DLA] for free.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

|

|

A. To be yet another stickler. While you are correct about the Types in regards to Hex and No-Hex, MIL-DTL-5541, does have 2 Classes. Class 1a and Class 3, each with their own subset of requirements etc. Production Technician - Horsens, Denmark August 26, 2024 Q. The QPL-5541-25 ⇦this spec on DLA lists a Type, Grade, and Class. I understand Grade translates into Form and Class 1 & 2 are now 1A, but I cannot find the explanation for type. Enrique Bejar [returning]Quality Engineer - Santa Ana, California August 26, 2024 |

A. Hi again Enrique.

I see that I didn't pay close enough attention to your question the first time around :-(

You are talking about a QPL which was cancelled more than 54 years ago. Apologies but I don't have and haven't been able to find a copy of MIL-C-5541 that old, so I don't know what Type 1 vs. Type 2 coatings meant way back then :-(

As a wild guess, it may have had to do with non-accelerated vs. cyanide-accelerated chromate coatings.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() I have yet to find the original MIL-C5541 as well. I appreciate your help.

I have yet to find the original MIL-C5541 as well. I appreciate your help.

Quality Engineer - Santa Ana, California

August 27, 2024

Q, A, or Comment on THIS thread -or- Start a NEW Thread