Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Electroless nickel plating solderability issues

Q. What can be done after Electroless Nickel plating to improve its solderability?

Nischal SureshEmployee - India

November 20, 2021

⇩ Related postings, oldest first ⇩

by G. G. Gawrilov

on AbeBooks

or eBay or

Amazon

(affil links)

by Sha, Wu, & Keong

on eBay or

AbeBooks

or Amazon

(affil links)

Q. What is the best type of flux to use in soldering electroless nickel (low phosphorus nickel or nickel boron applications)?

Eric Rule- Boone, NC

2002

A. The most aggressive flux you can find is the best. I believe it is called an RMA flux, I am not totally sure. There are also things that can be done after electroless nickel plating to greatly enhance solderability.

Todd Osmolski- Charlotte, North Carolina, USA

2002

A. In general, low phos and especially electroless nickel borons are considerably solderable. Todd's 'RMA' flux refers to Rosin - Mildly Activated and is typically the most aggressive permitted in electronic applications. Type 'RA' fluxes are the most aggressive but are too acidic for use in electronics. Weaker Type R's, straight rosin, won't cut it with any electroless nickel. Mid and high phos EN's are far worse for solderability.

Milt Stevenson, Jr.

Syracuse, New York

2002

Q. I work at a microwave electronics company. Many of our housings are aluminum plated with an electroless nickel finish. We then solder (sweat) PCB's of various types down to the plated housing. For small housings this usually works fine but for larger housings the sweating is difficult, at best. I've been told that adding a Bright Nickel finish, over the electroless nickel, will improve the solderability. I'd appreciate any thoughts or suggestions on this.

Bob Diamond- Hauppauge, New York

2003

A. Bob,

EN can be difficult to solder to and I suspect you are limited as to the flux you can use. As the EN ages soldering becomes more difficult. A nickel overcoat may be helpful but may have some of the same solderability issues as EN to a lesser degree. I would suggest tin plating over fresh EN, but with all the issues with tin whiskers a tin/lead may be the toxic answer (97% Sn,3% Pb) or better a tin/bismuth bath. Hope you get more feedback on this, as my mind's database on this stuff is close to the recycle bin.

Second thought, if larger PCB is harder to solder than smaller PCB. Are you using the same soldering tool? I large PCB may "drawup" more heat than a smaller one. Try a non-contact infra-red temp senor, RAYTEC makes a great "MiniTemp" $75.00 Do you see cold solder joints on large PCB? Can you use a stronger flux?

R=Rosin

RMA= Rosin Mildly Activated

RA= Rosin activated, also slang is Rosin Acid

Stronger fluxes can have a negative impact on component needs; follow specifications.

- Minneapolis, Minnesota

![]() Jon,

Jon,

Thanks for your suggestions. We currently are using an RMA flux, but soon we will have to switch over to a "no clean" solder system. Doing so will make the soldering even more difficult. We do this process on a hot plate and make sure everything is up to temperature before we start the soldering process.

- Hauppauge, New York

2003

Q. Hello,

Is there a specification (MIL, ASTM, etc.) that describes the solderability of electroless nickel?

Thanks

avionics - Kortrijk, West Vlaanderen, Belgium

2004

Q. We electroless nickel plate aluminum (6061 alloy). We need the electroless nickel to be solderable. What is the proper way to specify the electroless nickel plating? What factors affect the solderability of this type of plating? Thanks.

Bob Diamond- Hauppauge, New York

2006

A. From our own experience, using a high phosphorous content electroless nickel solution achieves good solderability. (High P EN).

Poobalan- Singapore

2006

! ! I don't have personal experience in soldering electroless nickel, but Poobalan's statement is directly contradicted in letter 34791 and several other threads with repeated assertions that mid phos is generally easier to solder than high phos, low phos is generally easier than that, and electroless nickel boron is the best choice when solderability is the major concern.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

January 30, 2013

A. Nickel oxidizes with age. Fresh EN should solder well, while stuff that has been on the shelf for a year probably will not.

James Watts- Navarre, Florida

2006

A. The avoidance of problems soldering EN is generally in getting the correct flux for the EN alloy you are working with (presuming you have a viable EN plate to work with).

Gene Packmanprocess supplier - Great Neck, New York

2006

A. I realise an extra process adds to the cost but immersion gold gives superb solderability for many weeks. You can use it to avoid flux. You can be selective about where the solder goes by selectively masking the gold to be preserved and immersing in gold stripper for a few seconds.

Nick Clatworthy- Whitstable, Kent, UK

2006

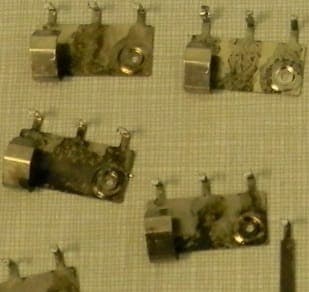

Q. We supply a customer of ours with a commercial mid-phos electroless nickel with a Deveco RP 6000 top-coat finish on a phos-bronze stamping. End user is complaining that when they solder the stamping to a PC board, they are experiencing a 20% fallout of stampings that are turning dark and discolored. Any idea what might be causing the discoloration?

- Naugatuck, Connecticut, USA

January 30, 2013

A. Hi. I could be in error, but I don't think you are supposed to apply a rust preventative to electroless nickel if you intend to solder it. Immersion gold (ENIG) sounds like a much better idea. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

January 1, 2013

Q, A, or Comment on THIS thread -or- Start a NEW Thread