Home of the world famous 'finishing.com HOTLINE' since 1989

-----

Science fair project: Electroplating with copper

For students wanting to understand generally how plating works and how to do a plating project, please start with our "How Electroplating Works".

Those in higher grades, or wanting a more scientific explanation of why plating works the way it does, the relationship between thickness of plating and current & time, etc., please see our "Faraday's Law of Electrolysis".

Q. Hi I'm Joseph I'm a student studying IB in Hong Kong and I'm currently doing a assessment where I need to write a lab report on Electrolysis, using copper as the anode and graphite as the cathode, and copper sulfate

⇦ on

eBay or

Amazon [affil link] as the electrolyte, and I was writing background information on this but I found it quite difficult to understand the research I was doing. The main questions I have are:

1. Scientific reasoning for how electrolysis works.

2. Why the mass of copper deposited on the anode is influenced by changing the voltage of the DC.

3. Same as 2 but by changing the concentration as my research question is how changing the concentration of the electrolyte effects the amount of copper deposited on the graphite electrode.

student - Hong Kong

March 22, 2025

A. Hi Joseph.

Faraday's Law of Electrolysis is the explanation to your questions. After reviewing it, get back to us if any clarifications are required. (Please include the initial of your surname; it's easier to follow stuff and help people when we know what other postings are from them).

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I am in 9th grade and am doing a project about electroplating. I have looked everywhere for information; in public libraries, bookstores, and on-line bookstores, and the only book I've got so far is useless to me (about the most valuable info I was looking for all the book said about it was: "chemical compositions of various plating baths is available from many sources and need not be repeated here"!). All other sources were out of stock or would take too long to ship any book (my project is due at the end of this month).

As I have gathered more info, I've seen that many types of electroplating involved hazardous substances (I could deal with not touching acids but avoiding acid mists from the electrolyte would be a problem). I think maybe plating of nickel would be safest, as opposed to chromium or zinc which have cyanide.

What I would like to know is which types of electroplating would be safest, and if any are okay then which one and what type of electrolyte I would need, how much cathode and anode ⇦ learn moreIn electroplating, the parts to be plated are negatively charged and comprise the cathode; the other half of the circuit is the positively charged anodes. Anodes are usually made of the plating material and dissolve into the solution to provide the necessary metal, although some plating processes use inert anodes which do not dissolve and the necessary metal is added as a metal salt. (on a small scale, to plate about as much as the handle of a fork or so), and how much current and voltage would be required.

Any help would be really appreciated. Thank you.

Andre G [last name deleted for privacy by Editor]- Falls Church, Virginia

2000

A. Hi Andre. Although I find it hard to believe that neither your town nor school library has an electroplating text or even an encyclopedia with a worthwhile entry under 'electroplating', you came to the right place. See our "How Electroplating Works" FAQ. We also have thousands of electroplating threads for as deep a discussion as you wish.

You are correct that chromium would be a very bad choice from safety and environmental aspects, but zinc plating is not necessarily cyanide based, and is a good choice.

We suggest that you either copper plate or zinc plate your item, using copper wire as the source of copper or sanded down pennies or a zinc boat anode ⇨

as the source of zinc, and with vinegar

⇦in bulk on

eBay

or

Amazon [affil link] as the electrolyte, and with the following additives:

- some epsom salts ⇦ on eBay or Amazon [affil link] to aid conductivity

- a little sugar as a brightening agent

- a drop of dishwashing liquid as a wetting agent

A 1-1/2 volt D-cell flashlight battery will supply enough voltage and current. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Thanks Mr.Mooney. But just what can I copper or zinc plate onto based on your solution?

On the FAQ I found two experiments on electroplating. One had an experiment, where you would plate zinc into copper pennies, that had the same solution except on this one you said to add dishwashing liquid. I was just wondering which one would work better. Also, it said to clean the cathode, but isn't it necessary to clean the zinc?

The other one was to plate nickel into copper or steel and the solution was nickel chloride (is nickel chloride corrosive or hazardous?). It suggested not to do that one because chlorine gas may be released. Well, as part of my experiment, in which I test which factors make electroplating faster, I would increase the voltage. Would that cause more release of chlorine (I read that somewhere in this site)? Thanks again

Andre G [returning]- Falls Church, Virginia

A. Your 9th grade science project should be an attempt to safely demonstrate principles, rather than to actually produce electroplating suitable for industrial use, so I think you should plate onto coins: for good contrast, zinc plate onto copper coins like pennies, or copper plate onto dimes and quarters.

A drop of dishwashing liquid will do no harm. Whether it will do any actual good in a 9th grade experiment is questionable: it just makes the water wetter. The cathode (the thing you are plating onto) must be absolutely clean because you are trying to build onto the crystal structure of the metal, and even a fingerprint will prevent that; the cleanliness of the anode (the material dissolving into solution) is much less critical.

I do not think you should do nickel plating, both because some people are allergic to nickel (nickel itch) and because any solution that contains chlorides (as nickel chloride does) can accidentally produce chlorine gas at higher voltages under unusual circumstances. This is why we suggest using epsom salt (magnesium sulphate) rather than table salt (sodium chloride).

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() THANKS a lot for all your help and advice. I'll do the experiment you suggested.

THANKS a lot for all your help and advice. I'll do the experiment you suggested.

- Falls Church, Virginia

A. Greetings Andre, I must really be getting old :-) -- I remember doing this same type of project for my 8th grade science project.

If I remember correctly though, since I've always been around plating I had the "commercial" grade copper plating bath and I copper plated a nail. The feeling I got when it worked was amazing, a whole new world opened up to me when that happened and science became a very important part of my life. Once you plate that first object don't be surprised if you get this unstoppable urge to dive deeper into the whole realm of metal finishing, it's a huge world and an extremely enjoyable one to be associated with. Good Luck to you young man, and hope to see you on the plating trails later in life (you never know).

Matthew Stiltner- Toledo, Ohio

Q. Thanks Mr.Stiltner :-)

On the FAQs, it said to leave the zinc in the vinegar for several hours so it would dissolve, and to have 100 g/l of the zinc dissolved. (Tell me if I'm wrong, but when you say 100g/l, you mean 100 grams of the substance per liter of vinegar, right)? I left the zinc for several hours, and I'm sure it wasn't close to the amount it said. But I was just wondering if I connected the zinc to the positive side of a battery it would help to dissolve the zinc faster and in greater amounts.

Andre G [returning]- Falls Church, Virginia

A. It might plate out almost as fast as it dissolved, so it might not help much. Further, you would probably lose some of the acidity, and that's a pretty precious commodity when you are deliberately using a very weak acid for safety reasons.

I'd let it sit and dissolve a while, but I'd agree with you that the dissolved zinc probably doesn't approach 100 grams per liter.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Dear Mr. Mooney,

We are trying to electroplate zinc onto copper pennies for our science project -- the effect of voltage on electroplating. We are using the recipe on your webpage. The copper is being plated but then disappears when taken out of the solution so that we can't accurately weigh the pennies. Any suggestions would be appreciated.

Sincerely,

Jesse H and Ben D- Oakland, California, USA

2002

A. The electroplating is awfully thin, probably just a few millionths of an inch. Between wearing off and difusing into the copper it may appear to vanish. I think you are going to have a very difficult time weighing such a thin coating. But if you electroplate for several hours or overnight, instead of for a few minutes, you might have a fighting chance. If you can get a science teacher to help you, you could use dilute sulfuric acid instead of vinegar and you could plate much faster, but it is too dangerous to do without training and protective gear.

Voltage is necessary to make the current flow, but is not a primary variable. A more interesting experiment might be the effect of current and time, since you would be working towards proving or disproving Faraday's Law of Electrolysis -- a very interesting and really important law which says that 96,485 coulombs (ampere-seconds) will deposit one gram equivalent of metal.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I am looking for science fair topics/ideas for my general chemistry students; preferably ones that don't require expensive/hard to get equipment, but require a solid amount of experimentation involving the classic situation of independent vs. dependent variable setup. If you have ideas that would be appropriate in terms of the above criteria as well as level of complexity for high school students, please let me know.

Thank you very much.

Joseph T [last name deleted for privacy by Editor]high school chemistry teacher - Cuba, New Mexico, USA

2003

Q. I am zinc plating pennies right now. Two things:

First, can you please tell me to which side of the battery does the penny have to be connected to, + or -?

Second, I made a solution by letting zinc sit in vinegar. The first time, I just put the penny in. The second time, using the same vinegar, I added salt and sugar. In about a day, I noticed that the clamp I connected the penny to the battery was almost completely eaten away. There was almost nothing left of the submerged part. The first time it was fine. Can you tell me why that happened?

- Daly City, California, USA

February 19, 2008

A. The object which you wish to plate onto is connected to the negative terminal of the battery. If you are doing this as a chemistry lesson rather than as play, you need to understand why, Dima, and it is explained in the FAQ you were looking at.

The solution is apparently far more corrosive with salt in it than with just vinegar in it.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thanks a lot. My science project was a complete success, and I got an award.

Thanks a lot. My science project was a complete success, and I got an award.

- Daly City, California, USA

!! Way to go, Dima. We're happy for you!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 22, 2008

Q. What happened! I have recently done an electroplating experiment (12 year old Grade 7) and something really weird happened the first time! Instead of the copper flowing over to the quarter from the penny the wires dissolved and the salt and vinegar solution got this green sludge in it! I want to know what went wrong because I'm currently doing the same experiment except its working the right way- the nickels getting covered with this black stuff. I just want to know what that green stuff was last time and why the solution got really powerful and dissolved everything! Thanks in advance.

Sam G.Student - Watauga,Texas, USA

August 22, 2008

A. Hi, Sam. The green color was apparently dissolved copper from the wire. If a copper wire is in the solution and attached to the positive pole of the battery, yet it will dissolve away quickly. As for the 'black coating though, are you sure the voltage was never above 1-1/2 volts?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Okay, Like I am in the 8th grade and I am wondering how this experiment works, since I got several questions of course.

1) The first thing I don't get is that am I suppose to add vinegar, salt, sugar, and dish washing soup all together one after another?

2) if so, how long do I leave it like that? Am I suppose to stir it or something?

3) What materials do you suggest? A copper Penny, a copper plate, and copper wires?

4) what is an anode?

5) How long do I have to leave the circuit connected until I notice something change?

6) Does it matter type of salt I use?

Thank you for your time...I appreciate it.

- Houston, Texas, US

September 9, 2008

A. Hi, Tony

1 & 2). Makes no difference. Just stir it a bit.

3). Our "How Electroplating Works FAQ" suggests plating a penny with zinc or a coin or brass key with copper. Copper wire is the best source of copper.

4). The anode is the positive pole in the circuit, and often it is made of the material that you wish to plate with, and supplies the metal by dissolving into the solution.

5. You'll see something happen in a few minutes with the zinc plating, it may take a half hour to see the copper plating start working.

6. You can use table salt.

Good luck and Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Good science projects for exhibition in school

Q. This project is for my science exhibition in my school's Founders' Day. Many chief guests are coming. It is the biggest event in my school. I have been told not to spend much money. If any good project in which I need not spend much money is there it will be very helpful. I have nearly 11 days left for completing it. I am in 8th grade.

amit k [last name deleted for privacy by Editor]student - gandhidham, gujrat, India

September 29, 2014

A. Hi Amit. As you read here, electroplating a copper or brass coin or other small object with zinc is quite easy and inexpensive.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Cell EMF = 0V

Q. Hi there,

I'm doing an experiment on electroplating that has a cell potential of 0 as the same metal is being oxidised and the released ions are being reduced. What does it mean when a cell potential is 0? The reaction is meant to work if voltage is applied to it. If voltage is applied to it, what happens that makes the reaction work as compared to without voltage?

- Perth, Western Australia, Australia

April 23, 2015

A. Hi Bob. It's fine to ask for answers, but if you don't understand the questions you're asking, it's vital to tell your teacher, so you make sure you understand what the exercise is about. How could you tell a right answer from a wrong answer if you don't know what the question means? Anyway ...

Imagine taking a single piece of metal and putting it into a liquid and observing that not much happens. Then you take a pair of tin snips and cut that piece of metal in half ... would we now expect something to happen between the two halves? That would make little sense. So if you put two pieces of the same metal into the solution you'll get no net reaction between them.

However, if you connect one of the pieces to the positive pole of a battery, and the other to the negative pole of the battery, the battery is going to try to pull electrons from the piece connected to the positive pole and pump them over to the piece connected to the negative pole. This will leave you with a shortage of electrons on the one, and an excess on the other. The metal atoms that are short of electrons will become positively charged ions and dissolve into the solution and be attracted to migrate over to the negative pole. When those metal ions reach the negative pole, their electrons will rejoin them and they will become atoms again.

So what will have happened, on net, is that some atoms will move from the positively charged pole to the negatively charged pole in two "halves": their electrons getting there through the copper wire and the battery, and their positively charged ions getting there by floating through the liquid. And the positively charged piece of metal (the anode) will melt away, while the negatively charged piece of metal (the cathode) grows thicker as additional metal plates out onto it. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. As described by Ted, not much would happen if you had used good distilled water as your liquid.

I think that you would be more probable to generate H gas at one pole and O gas at the other.

Now add a bit of salt or acid to the water and it becomes greatly more conductive. If your metal is copper, a bit of copper sulphate and sulfuric acid will give you a poor man's electroplating cell.

Change the negative metal to a clean piece of steel and you set up is no longer net 0 but is an effective demonstration of copper plating.

Vinegar (acetic acid

⇦ on

eBay

or

Amazon [affil link] ) would be a bit safer but less effective.

- Navarre, Florida

Q. Thank you for the answer.

Maybe I should have explained my experiment more. I have a copper and a zinc electrode with a zinc nitrate solution as my electrolyte. My zinc electrode is getting oxidised and the zinc ions in solution will plate onto the Copper electrode. Since zinc is being oxidised at one end and reduced at the other, the emf is 0. This is what I meant by the same metal being oxidised and reduced.

I'm failing to understand how this reaction would occur if the emf is 0. +ve means that it produces current and -ve means that it requires current for the reaction. What does 0 mean? It's definitely not spontaneous but if voltage was applied to it...? What happens in the cell that would drive the reaction to occur?

I also had another question about the effect of voltage. I understand that the rate of reaction is faster if the difference between the minimum theoretical voltage and the supplied voltage is larger. What is the explanation of why it is faster? Is it just the increasing current with increasing voltage according to the ohms law?

- Perth, Western Australia, Australia

A. Hi Bob. Are you seeing zinc plate out onto the copper all by itself or are you just predicting that it will happen? Unless your zinc nitrate solution is awfully strong, or unless you apply voltage to make it happen, I don't think it will happen. I encourage students to actually do their experiment before seeking explanations for a number of reasons; but one of the reasons is that you can find yourself trying to explain why things happen when, actually, they don't -- and soon you're hopelessly confused :-)

We can talk about Faraday's Law, and standard potentials, and the Nernst equation, all of which have great bearing on your experiment. But before we do, do yourself the favor of carefully documenting the setup, and the observations and facts that you actually record ... then the reason things happen the way they do will be easily explicable. You are not correct that the EMF is zero, unless you have applied electricity long enough to have caused a heavy non-porous layer of zinc plating to be deposited on the copper. I think you may confuse yourself by accepting that as a given or adopting that terminology.

If you have already applied electricity long enough that you now have two zinc electrodes with no copper exposed, and you are continuing to apply electricity and continuing to dissolve zinc from the anode and plating it out on the cathode, then we can talk about Faraday's Law and its bearing on the situation. But after two postings, what you have actually done and what you have actually observed or measured are still big question marks for me. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello again,

I have finished my experiment and it seems that increasing the voltage and concentration increases mass gain on the cathode. However, what is noticed is that the amount of mass lost doesn't correspond to that gained. Anode loses less mass, while cathode gains more mass. Also the mass transferred isn't accurate as far as Faraday's Law is concerned; it's a lot higher than predicted. Is there anything to explain these irregularities or is it just experimental error?

I have left the electrolytic setup running for 25 minutes which was more than enough to form a complete layer of copper.

There were a lot of bubbles on the cathode and I am theorising that water was reacting instead of zinc due to the depletion of zinc ions around the cathode. Is this right to assume this?

Also could the zinc react further with the water as this would explain the irregularity of anode mass change and cathode mass change not adding up. I have a basic understanding of galvanising and I believe zinc reacts with OH- to produce zinc hydroxide that covers up gaps. Could this be happening in this situation do you think?

Thank you.

- Perth, Western Australia, Australia

A. Hi. Re:"form a complete layer of copper". Is this a typo -- did you mean "form a complete layer of zinc ON the copper"?

While Faraday's Law remains fact, it doesn't actually say that you will deposit x number of grams of Zinc ... it says that you will reduce x number of equivalent weights of something at the cathode and oxidize x number of equivalent weights of something at the anode. Yes, that "something" may include hydrogen at the cathode and oxygen at the anode. The electrons you remove from the anode and pump over to the cathode will cause something to happen. Most of what will happen will usually be movement of zinc from the anode to the cathode, and platers sometimes talk about cathode efficiency and anode efficiency. If 80% of the electricity used causes deposition of zinc and 20% causes liberation of hydrogen from the water, we say the cathode efficiency is 80%. Similarly, the process at the anode will operate at some efficiency depending on concentration, amperage, voltage, temperature, pH, etc.

It is possible for the cathode efficiency to be different than the anode efficiency, such that you deposit more or less zinc than you dissolve from the anode. But this cannot continue for long because the zinc doesn't disappear; rather, the concentration of the solution increases or decreases accordingly. This is one reason platers must hold tight limits on process variables -- so the cathode and anode efficiency match up and the solution concentration stays in equilibrium.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi. I'm a 7th Grader at Mifflin Middle School. My dad has a Hull Cell ⇦ huh? at his work that my brother used last year for a project. I wanted to plate steel panels using different anodes (zinc, copper, etc) to see which is the best conductor of electric charge. Can I just use an ohm-meter like at science class? Do you have a good idea how to test how conductive each would be? Is this even a good test or should I try something else?

Mark H [last name deleted for privacy by Editor]- Reading Pennsylvania USA

December 14, 2015

A. Hi Mark. In the Hull Cell you will encounter a low resistance in the wiring, and a low resistance in the anode and cathode, but a high resistance across the liquid (the plating solution) -- so I don't think that particular experiment will work well because the low resistance of the anode will be masked by the high resistance of the solution.

Very few kids have access to a Hull Cell, which is a nice professional tool, so why not use it for the purpose that it was intended, and demonstrate what it can tell you (that the plating comes out differently where the anode is very close to the cathode than where it is far away from the cathode), how it tells you that, why it matters, etc.?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. You could try this: make an acid copper bath, and plate panels in your cell with varying amounts of molasses added. (Yes, molasses from the grocery store) You should see a substantial difference in the appearance and quality of the plate.

Dave Wichern

Consultant - The Bronx, New York

Q. Mr. Mooney: Hi. It is Mark again from Mifflin Middle School. I asked you a question about zinc plating in a Hull Cell. I got to work with the Hull Cell today and I tried different things with the Amps and with adding what the lab guy called 'wetters' and 'brighteners' and we dipped the panels in chromate solution after they were done. I took coating thickness checks and you were right about the distance of the anode from the panel being important. My next step is that I'm going to put the panels in a salt spray chamber to measure how fast they rust.

Here is my question:

I also tried to use the hull cell to put copper plating on panels, and that was a disaster. They were all flaky and bad looking. I found a video that said to use copper sulphate, but it didn't tell me how much to use. My dad said to start out small, so I did 700 ml of water to 70 ml of copper sulphate powder, and I think that might be too much, but I just can't tell. I also had to use lower amps (I went from 2 amps down to .5 amps and things got better but not great). Do you think I used too much copper sulphate?

- Shillington, Pennsylvania USA

(affil links)

free pdf is currently available from academia.edu

A. Hi Mark. Very few American high schoolers experiment with electrochemistry as deeply as you have already done in middle school. Congratulations to you, your dad, and your instructors :-)

Your copper sulphate concentration is low if anything. Please see the copper sulphate plating bath formulations in the Metal Finishing Guidebook.

Real copper sulphate plating baths involve sulfuric acid as well as the copper sulphate, and the lack of it is one possible source of your difficulties. But another is that copper sulfate based plating baths cannot be properly used deposit directly on steel because copper will spontaneously immersion plate onto steel with poor adheson. Do you possibly have access to brass Hull Cell panels? Good luck.

My first field trip as a fresh engineer nearly 50 years ago was to a plating shop in your general area with a name remarkably similar to yours -- any relation?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Good day Mark.

It is very refreshing to read about your project.

I learned about electroplating at your age also. Ted has given you the information of the basic solution composition of the acid copper bath.

I do not know how much info/experience that you, or your father have regarding plating.

I would like to add that you should use phosphorised copper anode material (if you are using brighteners) along with vigorous solution agitation in the hull cell. Are you making your solution with de-ionized/distilled water? Try to determine the amps per square foot on your panels.

Kocour is a company who could help you with the hull cell panels, andul they can supply a hull cell scale/ruler.

Keep up the effort.

Best of luck to you.

Regards,

Aerotek Mfg. Ltd. - Whitby, Ontario, Canada

![]() Thanks, Eric,

Thanks, Eric,

Yes, phosphorized anodes are required for continuous production; otherwise the copper concentration will rise high until the solution near the anodes becomes non-conductive. But I don't think a student will actually need them for a science project.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Mr. Mooney: Thank you for the book link. I will get my older brother to help me understand it. I think the problem is that we tried to plate over steel, not brass. We will try again. I am testing at Hofmann Industries, because my dad and grandpop work there, but they don't do copper so they let me try what I wanted to try. I will try to get some brass panels to try.

THANKS

Mark

- Shillington, Pennsylvania USA

![]() Hi again. Say hello to your grandfather for me. Although I don't remember him and he wouldn't remember me, his shop was indeed my very first field trip as an engineer, back in 1967 or '68.

Hi again. Say hello to your grandfather for me. Although I don't remember him and he wouldn't remember me, his shop was indeed my very first field trip as an engineer, back in 1967 or '68.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Andrea

My Father was the 3rd best known Electroplater in California for ten years as I grew up. He taught us kids all we ever needed to know about plating (of course some chemical and physics we need to look up now and then). Let me assure you anything using Sulfuric Acid is at best hazardous, be it plating or Anodizing you'd best be careful (breathing the fumes can and will cause lung damage, viewing the tanks too often or close can and will damage the eyes).

I'd say Copper Plating is best for you: first, copper is abundant and handy and you can get copper sulphate from Animal Feed stores or make it yourself. Further if you like and wish to not have smelly and touch contact issues use Ferric Ammonium sulphate or Ammonium Chloride (both are normally used in making Printed Circuit Boards as the diluted chemicals use no electricity to remove copper. To electroplate simply apply electrical (DC) a 1 1/2 volt batt but a 9 Volt is better and you are done, time in solution is the key to good work with only clean of oil, dirt and waste it's equal. Oh, by the way do you realize that on electroplating is the lowest form of Matter Transportation (Like on Star Trek)?

Edmond EdwardsNo BIZ like MY biz - Woodland Hills, California USA

August 5, 2017

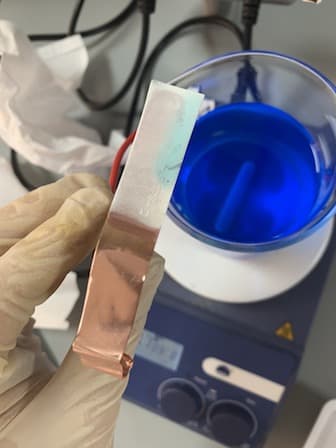

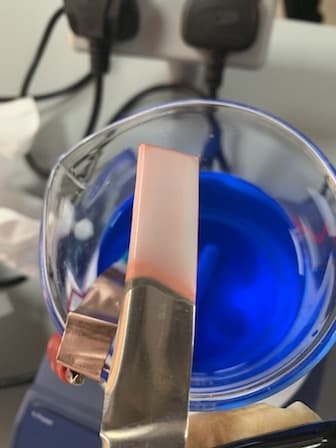

Q. White Precipitate Forming on Electrodes?

Currently doing a lab report in school regarding electroplating, using a copper acid electrolyte. I've been plating copper onto nickel strips. After about a minute has passed a white precipitate starts to form on both electrodes (Copper Anode & Nickel Cathode).

The formula of the electrolyte is:

250ml of Distilled water

10g Copper Chloride (CuCl2.2H2O Crystals) (0.04 g/ml)

25 ml Extra Pure Sulfuric acid (0.1 ml:1 ml Ratio)

48.75 g copper sulphate

⇦ on

eBay or

Amazon [affil link] (CuSO4.5H2O Crystals) (0.195g/ml)

4V applied in increments of either 5m, 10m, 15m, 20m, or 25 minutes.

Bath is kept at 80 °C and has agitation from a magnetic stir-bar set to medium-high.

- Abu Dhabi, UAE

February 22, 2021

No dead threads!

Your Q, A, or Comment puts this thread on The Finishing.com HOTLINE.