Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Help with gold electroforming

Q. Dear Sir,

I would like details of Gold alloy electroforming.

Precious metal brighteners.

Precious metal plating salts.

Photo-resist working temp. 90 °C and staying in plating solutions and Aqua Regia.

Raja R.A.Al-Ahmadi, KUWAIT

1997

A. Raja, Here are two suppliers of the processes you require: Degussa (Germany) and Enthone-OMI. Good luck.

Bob Lynch

plating company - Sydney, Australia

1998

Q. Anyone have experience in 18K (Au/Cu/Cd) electroforming and can successfully control within the range of 75~76% Au content? Need information!

Best Regards.

Mark Cheng- Hong Kong

1998

A. Hi, Mark. Sorry, I don't know the answer, but in addition to the companies mentioned, Technic has been offering gold electroforming processes around the globe for decades.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I am interested in trying my hand at gold plating as a hobby. I want to plate organic objects such as tree leaves or flowers. I have seen it referred to as electroforming. Do you have any knowledge of this process? As a hobby, I don't really want to spend a great deal of money on equipment. The results may not be what I want and I may abandon the idea. What would be an inexpensive way to try this out without having to shell out a lot of cash? If you don't know about any of this, do you have a source who may?

Thanks for any information,

Jerry L [last name deleted for privacy by Editor]1998

A. Hi Jerry. If you want to learn on a budget, start with copper plating not gold plating. Mistakes are very costly when you're dealing with something that costs $1000 per ounce :-)

Please see our FAQ on plating/electroforming on organic objects.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Thank you Mr.Bob Lynch for your kind advice.

Thank you Mr.Bob Lynch for your kind advice.

Mr. Jerry Landes: Please contact again for further discussion.

Thanks for FINISHING.COM for their generous help but do not want to say for the people who know but do not help.

God bless M/S Ted Mooney & Tom Pullizzi.

With salute and best regards

Raja R.A. [returning]Al-Ahmadi, KUWAIT

1999

Ed. note: Thank you, Raja, and God bless you.

A. Dear Raja,

which carat are you interested in? If you want 24K, you don't need a special system but only a good electroforming process that can give you a hard deposit, with enough mechanical resistance.

For other carats (14, 18 and 21/22) you need a dedicated machine.

I think Enthone Inc. is a company that can provide you updated technology in this field.

Regards.

Alberto

- Milano, ITALY

July 26, 2008

Q. Our company is interested to go into 14 K gold electroforming but we don't know the technology and the chemistry needed to make the solution. we also want to make gold potassium cyanide converted from 24 K to 14 K. Can we melt a 14 k gold using nitric acid and muriatic acid? If so what is the percentage. Also what is the anode that we must use for the gold electroforming?

Heide l. Cardenio- Metro Manila, Philippines

1999

1999

A. Hi Heide l. Cardenio

Gold electroforming is a long process. Anyway, I will suggest to begin with 18 K gold electroforming where the technology knowledge is fairly established.

Process

Mould preparation using low melting alloys

Cyanide copper plating

Bright acid copper plating

ELECTROFORMING

- Vicenza Italy

2000

A. Heide, The best electroforming I have seen is a process from Degussa in Germany. In this process the models are simply the waxes used for investment casting which are coated with a conductive coating then electroformed in the carat rating required. The process is however sold as a package (that is, you have to buy the machine with the computer controller as well as the plating processes).

Regards

Bob Lynch

plating company - Sydney, Australia

A. Hello Heide. In the USA and much of the world, people do not attempt to formulate their own electroplating solutions; rather, they buy them from vendors like DeGussa, Technic, and others who have done decades of intensive development work; and Bob is doubtless right that you should stick with well developed 18K rather than trying 14K.

You can probably use stainless steel anodes in many cyanide gold plating baths. Although 24K anodes could probably be used, no one does that because of the cost and value of such anodes. 14K anodes would never work because gold is more noble than the copper, silver, or whatever other metal you would melt into it; studying the Nernst equation will reveal what the problem is.

It is obviously difficult to cover the whole technology of gold electroforming in a forum response, since it fills chapters if not whole books, but we'll start a topic here which will hopefully eventually cover a lot of it.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Please tell me where I can purchase ammonia

⇦ this on

eBay or

Amazon [affil links] gold sulphate^sulphite for electroforming and why the sodium does not work properly.

- UK

2000

? Hey Chris, Are you sure of the sulphate? I know that sodium gold sulfite is used in a non-cyanide gold plating system. Regards, Fred Mueller, CEF

Fred Mueller, CEFWendt Dunnington - Royersford, Pennsylvania

2000

Q. Sorry for the spelling mistake. I really mean ammonia gold sulphite this seems to work much more consist than the sodium for some reason, it is possible to add other alloys in very small quantities to make a better solution. I am so grateful to you for your kind reply thanks.

chris wilks [returning]- uk

2000

A. Chris, Try Degussa in Germany or your local agent. They have a range of electroforming processes.

Bob Lynch

plating company - Sydney, Australia

2000

Q. I am interested in gold electroforming. I need to know the chemical composition of the gold solution, anodes to use and the process involved. I really need assistance on this matter.

Utoomporn k [last name deleted for privacy by Editor]- Thailand

2000

Q. Dear Sir:

I would appreciate to know about gold electroforming (solution, operating condition, the electroforming technology, current density, bath, brighteners, and so on). I saw in the papers that all the baths are cyanide gold. I have questions about the danger of it, and what care you must take. Are there other baths of non-cyanide gold I could use, free of maintenance?

Sincerely yours,

Zulema Angela Mahmud- Buenos Aires, Argentina

2001

by Reid & Goldie

-- hard to find & expensive; if you see a copy cheap, act fast!

on eBay or

AbeBooks

or Amazon

(affil links)

A. Hi Utoomporn, Hi Zulema. It's a broad subject but Reid & Goldie's 630-page book on good plating has a 15-page chapter on the electroforming specific issues .

I do not believe that all the baths are cyanide gold but there are advantages in sticking with the proven standard.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. On the subject of gold electroforming solutions, there is also one made by Metalor, formerly Engelhard, called Enform 18P. You might like to contact the office in Cinderford Gloucestershire England.

Good luck!

Les C [last name deleted for privacy by Editor]University of Central England - Birmingham, England

2003

Q. I am interested in gold electroforming. I need to know the chemical composition of the gold solution, anodes to use and the process involved. I really need assistance on this matter.

Thank you

ILA L [last name deleted for privacy by Editor]- Roma , Italy

2004

Need info on very thick gold sulfite electroforming

Q. Hi,

I am an artist/goldsmith and author. I want to build a gold electroforming bath using gold sulfites (potassium or sodium?). I understand that stability of these solutions is fussy and they need buffering with sodium sulfite. I would like to be able to electroform to .5 to 1.5 mm thicknesses. I do not care about nodule formation, in fact I would like that. As well, a bright finish is nice, but not necessary as I can tumble the finished gold objects. I would like to be able to make up bath replenishing solution myself if possible to lower costs. Can anyone advise me here? What formulas, equipment etc are specific to doing this with sulfites? How tricky is it to maintain the bath? I do not care how long it takes to grow the metal (well, within reason).

Thank you,

Charles Lewton-BrainArtist/goldsmith/researcher - Calgary, Alberta, Canada

2004

2004

A. Dear Charles!

Gold sulphite bath is not something for Do it Yourself work,but I think you can use ferrocyanide bath (0,5-1% of potassium cyanide toxicity). I am metalwork conservator and we used it for silver electroforming and it works.

potassium ferrocyanide

⇦ this on

eBay

or

Amazon [affil links]

.....200 gm

Potassium carbonate.......40 gm

Gold chloride............. 50 gm

Water......................1 lit

stainless steel anode,or platinum plated titanium (never mix solution and acids)

- Cerovski vrh Croatia

2004

A. Charles,

In the early 70's, I worked for Sel-Rex, the first maker of sulfite gold plating systems. One of the many things that I was in charge of was the manufacture of sodium gold sulfite. The process is dangerous - maybe even more so than the cyanide you're trying to avoid. There are bad acid fumes and, at one point, there is a great danger of producing the extremely explosive gold fulminate. Besides this, the process is tricky, exacting, expensive, and requires a good production chemistry background. The process was patented in the late 60's. The patent is about the only place that you'll find out where to make it. No one is going to tell you how.

Do the smart thing and buy the solution ready made. I would strongly suggest buying from Technic. They have always been innovative and helpful and they know as much about sulfite gold as anybody. Ask a lot of questions. Make sure the bath will plate to a thickness of 1.5 mm (.059"). Sulfite gold is not that easy to use. When things go wrong (and, they will), you'll many times need the free (usually), instant, expert advice that ONLY a supplier can give you - that's what you're paying for. Plus, you'll end up with a better, more reliable system. It's usually penny-wise and dollar-foolish to try and make your own chemicals or solutions, whether you're plating gold, nickel, silver, or whatever. Only amateurs do this, thinking that they'll save money.

A cyanide solution, containing about 4 tr.oz. of gold per gallon and using gold anodes, may still be the best (and, cheapest - and easiest) choice for electroforming gold. Technic, or other good gold bath suppliers, could sell you the PGC, give you a good bath formula, and tell you how to set it up and use it. Cyanide is safe if you know what you're doing and do it legally. It's not something you do in your garage. Check out thread #25979, read plating books, and search for other cyanide info on this forum and the internet. Be prepared.

Otherwise, find a plater. For small volume, this is your best choice. However, it makes experimentation more difficult.

Chris OwenConsultant - Houston, Texas

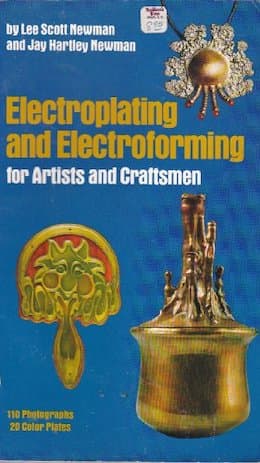

by Jay H. Newman

on AbeBooks

or eBay or

Amazon

(affil links)

"Amateurs do this, thinking that they'll save money."

Good point, Chris. Professional platers rarely try to design their own process chemistry, whereas amateur platers often try.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Hello Charles and plating colleagues, normally I would agree wholeheartedly with the advice given to "amateurs" embarking on this journey called electroplating. However, Charles is no amateur in the sense often used in this forum. Mr Lewiston-Brain is an accomplished technical researcher and practicing goldsmith. He is internationally recognized for his efforts in raising the safety awareness for practicing artists to the wide array of health hazards often encountered in the field of goldsmithing, sculpture and jewelry. He is highly regarded within his field and has provided accurate and easily understood information to anyone who would listen, especially educators. I have no doubt he will safely find a solution and methods to meet his requirements.

Charles, you are on the right track with regard to sulphite based gold chemistry for electroforming. Avoid the ferrocyanides; remediation is not good for this family of chemistries. As mentioned,there are commercial chemistries you can purchase that will meet your needs. Contrary to popular belief there are few people left within those companies mentioned that have the "actual" intimate and direct information (gold electroforming) based on empirical discovery which could help you. However,they can provide general principles and guidelines to follow if you can locate the right person. Other elements that will be critical to your success will include selecting the correct power supply, temperature and metal density of gold bath, agitation as well as numerous other variables which will need to be included. The cost for procuring the equipment, chemistries and the time to bring all the esoteric elements together is no small feat even for the accomplished plater. A very high degree of process control and bath monitoring is essential. You are probably familiar with the remarkable work of Stanley Lechtzin with regard to electroforming with copper. You will find that gold electroforming is significantly different (tougher) in chemistry, correct waveforms, and as you know costs.

By the way, try contacting Neil Bell from Red Sky Plating as he also has expertise on this topic and has been consistently generous and gracious with his knowledge.

Best regards,

David VinsonMetal Arts Specialties - Leonard, Michigan

2004

Ed. update Feb. 2025: Neil Bell has retired and his Red Sky Plating is closed :-(

Thanks for the many years of support of finishing.com, Neil.

Thanks, David. I stand admonished for calling my betters "amateurs" :-)

It was a bad choice of words. I am in awe of how metal-working artists do what they do! What I probably should have said is that people who do industrial electroplating learn that there is a whole industry out there that has worked for decades towards optimizing plating processes and offer them as proprietaries, whereas people who aren't into high volume plating may not realize that this is the customary approach and assume that they must make up plating solutions themselves from raw chemicals as they remember from chemistry class.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2004

A. Dear Charles!

I have used ferrocyanide bath over 10 years and I can tell you that it is very stable and easy to prepare.I have used it for gold plating, not for electroforming (2,65 gm gold chloride,15 gm potassium ferrocyanide ⇦ this on eBay or Amazon [affil links] ,15 gm sodium carbonate ⇦ this on eBay or Amazon] /for electroforming bath must be concentrated).

From financial point this type of bath is much cheaper than any proprietary product and, last but not least, several good books mentions it: Lowenheim's "Modern Electroplating", 1963 [on AbeBooks, eBay, or Amazon affil links] ; Dettner/Elzes Hanbuch der galvanotechnik/1963. If you don't want to work with it simple chloride based bath is also one possibility.

Chloride base bath:

gold chloride.......25-40 gm

HCl (1,19 gm/l)......20-50 gm

sodium chloride.....10-30 gm

H2SO4 (1,84 gm/l)....10-20 gm

water................1 lit

temp.................70 °C 8-10 A/dm2

Good luck!

Goran Budija- Cerovski vrh Croatia

(You're on the 1st page of this topic) Next page >

Q, A, or Comment on THIS thread -or- Start a NEW Thread