-----

Best Woods Nickel Strike ASF

Q. Our specification for plating SS calls for Wood's Nickel Strike 10 - 20 ASF. This matches the old ASTM B656 [withdrawn 2000] Appendix A mandatory requirements. During a Supplier Audit our supplier stated it would be better to use 20 -100 ASF, but could not provide any specification that stated this range. Is there a downside or is it more beneficial increasing the ASF range 20 - 100 asf?

Thanks,

2006

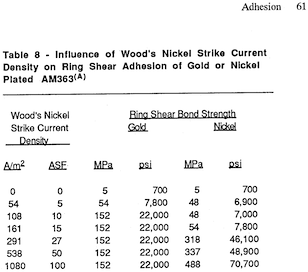

A. Jack Dini's wonderful "Electrodeposition" is a "must-read" for this topic because it includes actual bond strength measurements at different ASF. To summarize it in one phrase, though, your supplier is on the right track.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

2006

A. Years ago there was an article in either Metal Finishing or the AESF magazine. Bond strength rises rather linearly to about 90 amps, has a tiny hump to about 105 amps and then falls like a rock above that. I used 90 as an optimum and gave a reasonable amount of room from the falling area.

James WattsNavarre, Florida

2006

Q: How many amps are needed to nickel strike onto steel?

erik yoderAugust 25, 2013

A. Hi Erik. We appended your inquiry to a thread which addresses it. Such things may vary depending on the substrate and what kind of plating you're putting on top of the nickel strike, but James figure of 90 ASF sounds like a good one. Here is a tiny excerpt from Dini's book which hopefully he and his publisher will consider fair use since just the "Adhesion" chapter runs 44 pages .

But why would you nickel strike plain steel? That's a process usually used on stainless steel or to activate nickel plating.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

August 25, 2013

Q, A, or Comment on THIS thread -or- Start a NEW Thread