-----

Variegated appearance in sulfuric anodic coating

2006

Hi. I've been doing a lot of research about anodizing. I'm now familiarized with the procedures suitable for chromic acid and sulfuric acid anodizing.

The motive is that I received defective parts of a local company for my research project at college (University of Costa Rica). We must find the source of those defects and later design a theoretical anodizing line for the processing of those parts. The line won't be built. This is a graduation project.

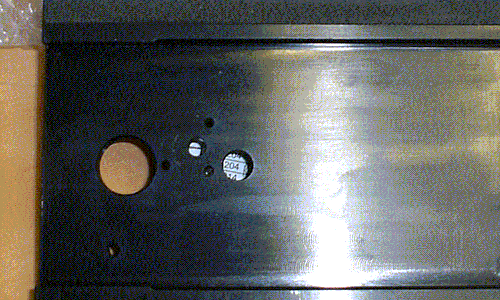

One of the parts has a variegated appearence with different tones of gray. It was sulfuric anodized, what you call type II. It also has like stain from some liquids or something (like the marks left by a spilled liquid on a table). What might it be? I'm almost sure it has to do with defective rinsing or cleaning. Perhaps the alloy?

Student - San Jose, Costa Rica

I forgot the picture. I must say that some other pieces in the same batch presented pores and white spots. I know what the white spots can be (I've already learned the section on this site about that topic) but I'm not sure about the pores (or may I say holes).

Arnoldo Castro CastroStudent - San José, Costa Rica

2006

First of two simultaneous responses --

Were you going to post a picture? It sure would help in this case.

Marc Green

anodizer - Boise, Idaho

2006

Second of two simultaneous responses --

It sounds like a possibly burnt part with potentially bad rinsing and some pitting. Look into those topics and you may find what you are looking for.

Good luck!

Compton, California, USA

2006

2006

One possibility is that it had some corrosion on it. The anodizer might have etched it long enough to clear that area which can cause the rest of the part to over-etch. They also might not have etched it long enough. It is possible that the sheet had deep corrosion and

nothing the anodizer could do to fix it. It would require something like a dual action sander of a timesaver to fix the problem.

Far out, they spilled coke on it and let it dry.

- Navarre, Florida

Q, A, or Comment on THIS thread -or- Start a NEW Thread