Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Steam Blackening Process

Q. I read something about black oxidizing by means of subjecting the workpiece to superheated steam (300 °C or about 600 °F). Can we instead heat the workpiece, and quench/dip it to water? I am asking this because heat treatment process also produces a black finish. I am wondering whether this black finish is actually a black oxide layer, or is it just a scale?

Thanks,

Hartarto Ciputra- Surabaya, Indonesia

2003

Q. Hello, I am tying to find out about the process of steam blackening. I have heard about companies that heat steel parts up to 1100 °F and then introduce steam to create an Fe304 surface. While this sounds great it is more of a heat treat than a finish and it destroys the temper of the parts.

What I make are Laser cut Bicycle tools and I have been zinc phosphating them for years but I have never been supplied with a consistent finish, and it is too easy to scratch through the Phos and see shiny metal as a result so I have basically given up on this form of treatment. However my Taiwanese competition has also been using Zinc Phos but they have a very hard and very black coating under their Phos that does not scratch off easily and the closest I have heard about is steam black under Phosphate. A name that has been mentioned is Nippon Grease (in Japan) and they make something called Blacker-4929. Are there any suppliers of the process or the chemicals.

Thank you.

Paul Bestlaser cutting - Wallingford, Connecticut, USA

2005

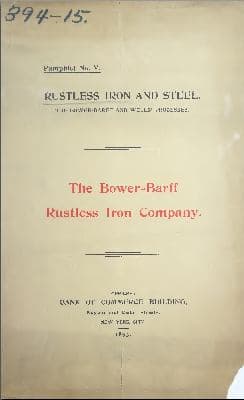

A. Preheated steam blackening is comparatively old (128 years) and somewhat expensive process -- old name for it is Bower-Barff process. .

Other similar processes exists too (Wells, Gesner, Bradley, Bontempi, Coslettizing). Objects must be heated to 1000 °C, then steam heated to 538 °C must be introduced to furnace (according to old books).

Hope it helps and good luck!

Goran Budija- Cerovski vrh Croatia

2005

|

|

Q. Well, - Wallingford, Connecticut, USA 2005 A. You may try blackening oxide with blackening solution at normal temperature, the blackening film is wearable and anti-erosion. Sundy Wu- Shenzhen, Guangdong, China 2006 A. DEAR PAUL  Khair Shishani aircraft maintenance - Al Ain, UAE 2006 A. Hi. Since these are tools, I'm not seeing why they need to be phosphatized, which opens us up for the good idea Cair has suggested for black chrome plating; tools have been nickel-chrome plated for a long time, and black chrome plating is little different. Another possibility is salt bath nitriding / QPQ (quench-polish-quench) -- it's both very hard and quite corrosion resistant. Regards,  Ted Mooney, P.E. Striving to live Aloha finishing.com - Pine Beach, New Jersey July 2014 |

Q. We are presently using an industrial heat steam system for blackening steel. However we are getting both dark and light blotches on our product. No consistency. Any thoughts?

peter skalsky- hibbing Minnesota USA

July 29, 2014

November 2016

? Hi Peter. My first thought would be why do you want to continue to use an old & expensive process that isn't giving satisfactory results instead of switching to a newer better one? Thanks.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Black Oxide finish for iron "Bower-Barff" finish

Q. Hello - I am a graduate student doing research on the Bower Barff method of rustproofing metal. It was a historic method of creating a black oxide finish on metal. I have some questions about the process. Can any of you help me?

Thank you.

student in historic preservation - long grove, Illinois

November 22, 2016

A. Hello Jeanne. We appended your inquiry to a thread which already addresses it. Please click on the graphic above to read about the Bower-Barff process and then pose your questions. Thanks.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

November 2016

Q, A, or Comment on THIS thread -or- Start a NEW Thread