Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Glass cap binds to stainless steel housing

We are having problem with one of our products.

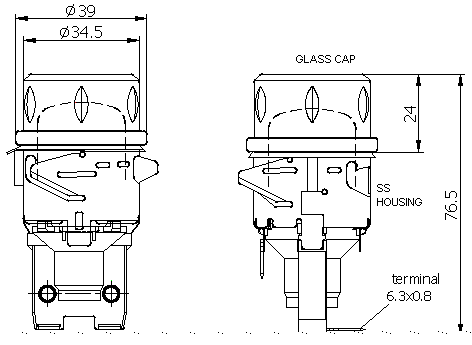

The product is a cooker (oven) lamp holder. The body is ceramic and there is 300 series stainless steel around the ceramic body with screw threads on the stainless part. Finally, there is glass cap attached to it to protect the light bulb inside. ( The whole product has a circular shape and the glass diameter is about 1.4'').

The problem is; it is not possible to unscrew the glass cap from the stainless steel housing ( shaped from steel sheet) after the lamp holder is subjected to heat for about 100 hours . The temperature in the oven is not more than 600 F. During testing, there is no material in the oven to create any pollution that may go between threads and stick on them. Unscrewing of the glass cap is important because, in time the bulb may burn and the end user may want to replace it.

When we examine the parts after testing, we see that threads on the glass look whitish and the stainless steel looks brownish.It looks like there is a kind of oxidation on the stainless steel this temperature. Also the surface of the glass seems to be affected somehow.

We are looking for a finish which we can apply either on glass or the stainless sheet to prevent sticking of these 2 parts with each other.

Mechanical Engineer - Istanbul, Turkey

2005

Hello Mr Atalay,

I think you may need a small design change to avoid having threads on the glass and the ss. Heat is probably expanding and distorting the fitment. The corrosion products that you see jamming the assembly are probably atmospheric corrosion residues.

You may try a bright blue decorative chrome flash of 0.3 microns on the SS directly, without any nickel plating underneath. I dare say it may work.

Write back if you have any success with the chrome.

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

2005

Hi Suavi,

I agree with Khozem's feelings about expansion.

There are metals that have a lower expansion rate such as, going by memory, Inconel. You could get better data on that from specialty metals USA or speciality metal Wiggin which is in the UK.

Your problem reminds me of the troubles people had with the early light bulbs ... which used to fail after a few hours or so ... until they found a metal (Inconel ?) that had the same expansion rate as the glass and thus prevented/retarded any oxygen entering the bulb and causing the filaments to burn out.

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

2005

Geez, Freeman.. you ARE old! Weren't light bulbs invented in the 1800's?

Marc Green

anodizer - Boise, Idaho

2005

Q, A, or Comment on THIS thread -or- Start a NEW Thread