Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Info about unusual surface roughness symbols

1999

Q. Respected Sir,

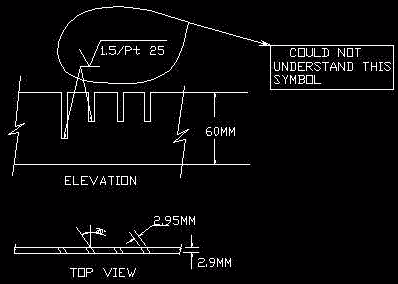

I require some detail information about the surface finish symbol shown below:

It is 2.9 MM thk. and 60 MM wide. There are slots of 2.95 MM width at an angle of 30 degrees each at a pitch of 26 MM. The dimensions are according the DIN standards. The term "1.5/Pt 25" has to be understood.

I was really happy to get some interest for my topic. Looking forward for your co-operation.

Thanking You,

Yours Sincerely,

UMANG CHAVADIAA. The American National Standard ASME Y14.36 establishes the profile for surface textures. The roughness sampling length is placed below the horizontal extension.

Bruce Solana- Panama City, Florida

2000

Q. I have a drawing of a cast steel component. One of the drawing notes contains a finishing mark I have never seen before. This mark starts with the Roman numeral III followed by the check-shaped finishing mark. The entire note reads: III(check-mark)Surface Quality per 2A 296-1004. What does this mean?

Thank you.

John Bauchat- Milford, New Hampshire, USA

2002

Q. We have a customer drawing that specifies 1.0 Finish mark, and under the mark it reads 0.4 / Rt 6.3 with a "C" under the 0.4

What do all these numbers and letters mean?

job shop employee - Jackson, Michigan

2007

Q. We have a customer drawing that specifies:

"0.9/Pt6" above the Finish mark

What do all these numbers and letters mean?

Appreciate your response.

- Singapore

March 14, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread