Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Looking for explanation of electroforming process for CDs/DVDs

for Artisans, Jewelry, Crafts

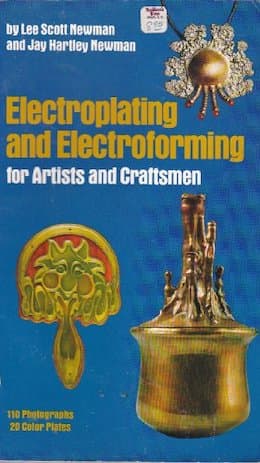

avail from eBay, AbeBooks or Amazon

avail from Amazon

avail from Amazon

avail from eBay, AbeBooks or Amazon

avail from eBay, AbeBooks or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

Q. I work in a CD/DVD Plant, I know how to make Mothers/Fathers/Stampers from the Glass master, but the thing I am wondering is exactly how it all works. Is there a resource somewhere on the net that actually explains it all, it seems that no one I work with really even cares about how the process works, they are just there for the paycheck.

I want to have the ability to actually break down and explain to people what I actually do rather then just say I make cds/dvds.

Thank you in advance for any Link you may have that would help me.

Electroform/Finishing - Scranton, Pennsylvania, USA

2005

A. Your ambition is laudable, Jeremy! Unfortunately I don't quite understand your question. If you already know how to make each progressive stage from the glass master to the stamper, and you realize that the stamper is used as the mold for the CD, what is it that you're not understanding? There really isn't a difference between a father and a stamper. The reason you go through those additional steps is that if you used the father as a stamper, production would be limited and it would wear out. By making mothers (reverse images of the father) you can make stampers (reverse images of the mothers).

If you google "mother father stamper" you'll find some sites that explain the steps.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I meant, what I wanted to learn about was the actual process, not just the manual labor of moving stuff around and pushing the buttons to turn on the machines.

I'd like to know how the solution and the different current makes an exact duplicate of the original plate but reversed.

Why and how it works basically.

They teach you enough to run the machines, but they don't explain what actually happens at all which is what I want to know.

- Scranton, Pennsylvania, USA

A. Okay, I understand now. I didn't realize that with the automated machines they had you so far away from the actual process that it was hard to know what was going on.

The overall process is called 'electroforming', which is actually exactly the same thing as electroplating except for the name, and CD manufacture is also quite similar to vinyl record manufacturing -- it's just that the little holes in a CD are much smaller than the grooves in vinyl, so small that might not see them or recognize what you are making. But a stamper or 'mold' does have tiny little projections, much like a music box but hundreds of times smaller, and those projections in the stamper/mold make the holes in the CD. The laser that reads the CD gets a reflection or lack of reflection because of the holes, and the millions of holes constitute the digital data which the CD holds.

So, in between the glass master and the CD is a series of mirror images. Where the master has holes, the father which is plated from it will have projections. The mother which is plated from that will have holes due to the projections on the father, the stamper will have projections due to the holes in the mother.

First the glass master is metallized (made conductive). In vinyl record shops this was done by spraying it with silver nitrate and a reducing agent to cause it to get coated with silver. Your CD shop probably does this metallizing in a vacuum coating machine instead.

Our FAQ on "Faraday's Law" has graphics that may help you visualize the following discussion on electroplating:

Now that the master is metallized and can carry electrical current, it can be placed on a spinner table in a vat of nickel sulphamate solution. When DC electricity is applied, negatively charged electrons flow through the wiring away from the anode to the master. Because the anode is made of nickel metal, when the electrons are removed from those nickel atoms, they get converted to positively charged nickel ions and dissolve into the solution. Meanwhile the master is accumulating negatively charged electrons which attracts those positively charged nickel ions; and as the negatively charged electrons re-join the positively charged nickel ions, we once again have neutrally charged nickel metal atoms formed on the stamper. This is continued until the plating is thick enough to have mechanical integrity and to be able to function as a father.

Then the father is separated from the master and mounted on the spin table in the plating machine, and through a similar process, the mother is formed from plating on the father. One more similar step and you have the stamper/mold.

That's the basic principle. If you're interested, you can get books about electroforming or electroplating. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q, A, or Comment on THIS thread -or- Start a NEW Thread