-----

Nickel/Teflon coating helps mold release?

2005

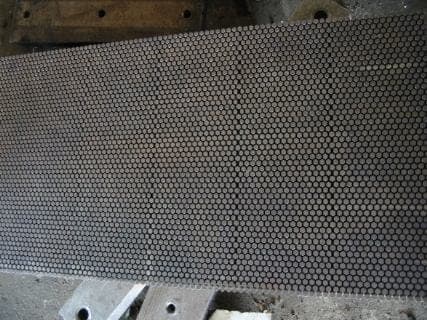

We are making a mold for PP injection, it has over 4000 honey cell size head on top of a plate. The plate size is 420x220 mm, and the cell size is 4.2 mm side to side, spacing between two cell is 0.7 mm, it makes the polishing really hard to accomplish. We have finished the EDM work but the surface is not smooth enough so we have release problem during our process of injection.

We were told by some people it needs to be Nickel/Teflon coating so it could do the job. After 3 days searching, we don't get this service available. But we do have Electroless Nickel plating service, is that enough to make the surface smooth so we could make the mold work? Or is there anything we need to do.

LEON ZHANG- JIAXING, ZHEJIANG, CHINA

You seem to have two different problems there. One is the scale left by the EDM process. Anything you want to plate on top of your mold surface will require the COMPLETE removal of that scale. Second, electroless nickel (EN) plain or composite with Teflon will NOT smooth out any surface but will tend to copy it, because its leveling ability is very limited. So, you absolutely have to polish the mold. It will improve by only doing it and will improve more if you plate it. EN will be good, EN+Teflon will be better but more difficult to get.

Guillermo MarrufoMonterrey, NL, Mexico

2005

2005

Leon,

I have found that ENi has improved mold release. So, I think it be worth a try. If you can not polish, you could try a fine glass beading the area. Be careful with the glass beading.

I am in the process of evaluating ENi, ENi with PTFE and ENi with Boron Carbide. To determine the best mold release.

- Elgin, Illinois, USA

2006

Our company is making some insert molding tools, a metal part is molded together with plastic part, the metal part will cause abrasion and scratch to the mold, and what's more the precision is also a problem. I want to coat some Teflon on cavities, which may possibly solve the two problems.

Elgin, do you have any experience with that?

Thank you

- Shenzhen, China

Q, A, or Comment on THIS thread -or- Start a NEW Thread